Speed-adjustable sealed vibration sample preparation crusher

A sealed, pulverizer technology, applied in the direction of non-rotational vibration suppression, grain processing, etc., can solve the problems of increased equipment power consumption, high temperature of the bowl, and failure to achieve fineness, etc., to achieve improved crushing efficiency, high efficiency and high The effect of mass crushing and mass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

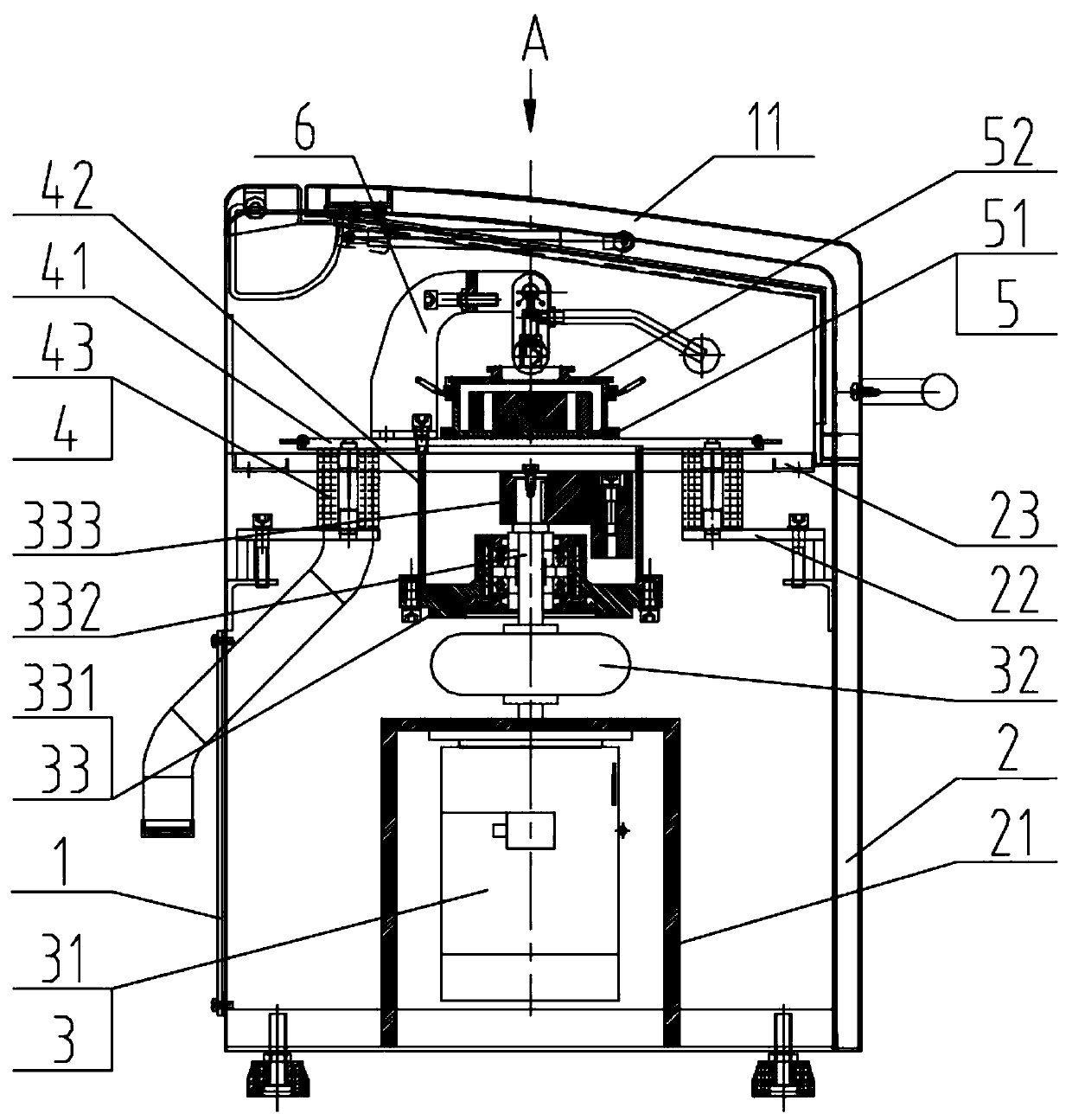

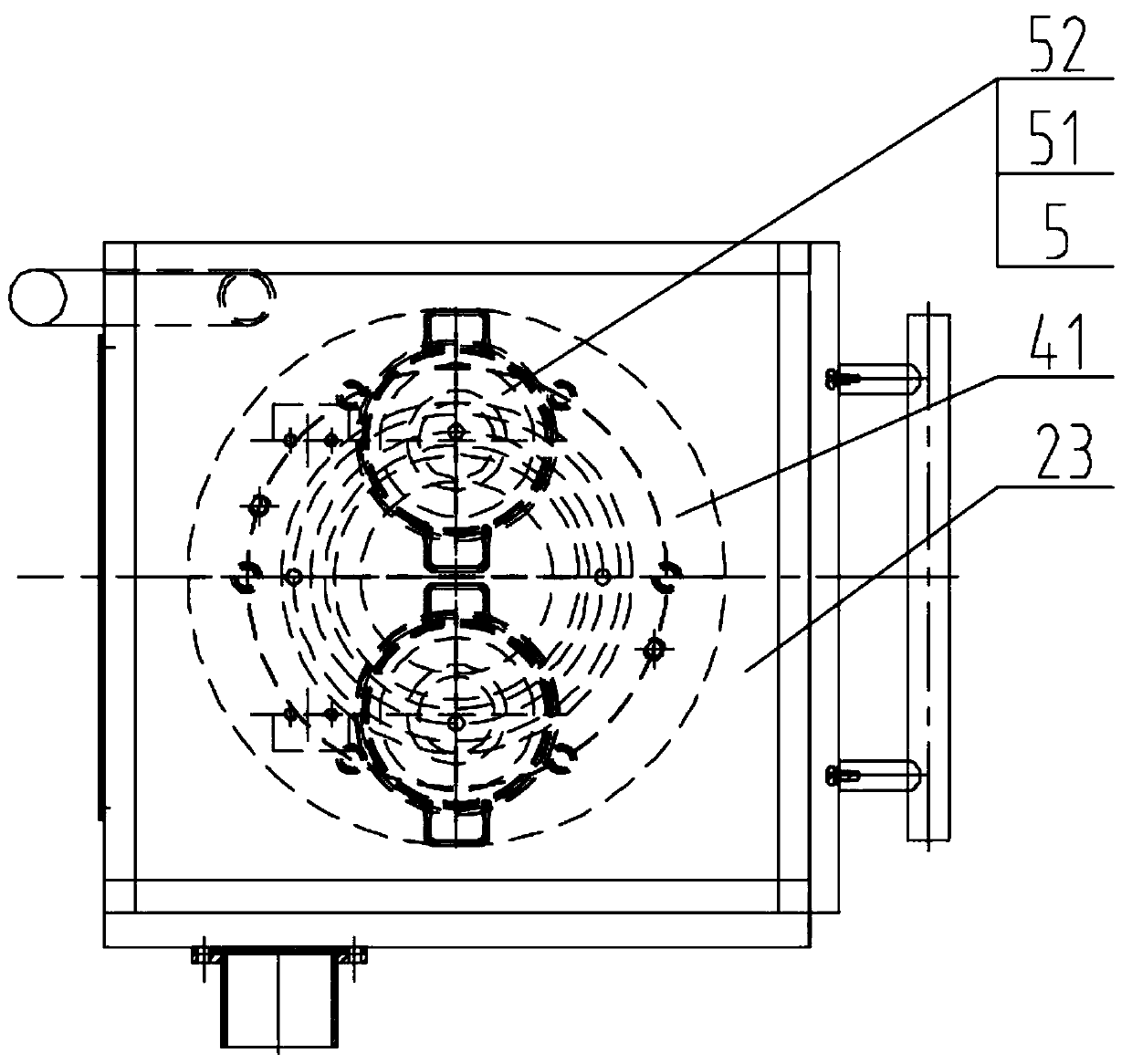

[0025] Such as figure 1 , figure 2 As shown, the speed-adjustable sealed vibrating sample pulverizer includes a casing 1, a supporting frame 2, a driving device 3, a vibrating device 4, a grinding device 5, a pressing device 6 and an electric control device.

[0026] The shell 1 is wrapped and mounted on the outside of the support frame 2, and includes an upper cover 11, which is hingedly mounted on the upper part of the shell 1, and the shell 1 plays the roles of sealing, safety and aesthetics.

[0027] The inside of the support frame 2 includes a motor support frame 21 whose installation position is located at the center of the lower part and a shock-absorbing platform 22 whose installation position is located at the upper part.

[0028] The drive device 3 includes a drive motor 31, a shaft coupling 32 and a vibrator 33; the drive motor 31 is fixedly mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com