Rubber composition for anti-vibration rubber and anti-vibration rubber for vehicle

A rubber composition and composition technology, applied in vehicle parts, shock absorbers, transportation and packaging, etc., can solve problems such as high loss, low dynamic magnification, and dynamic magnification improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

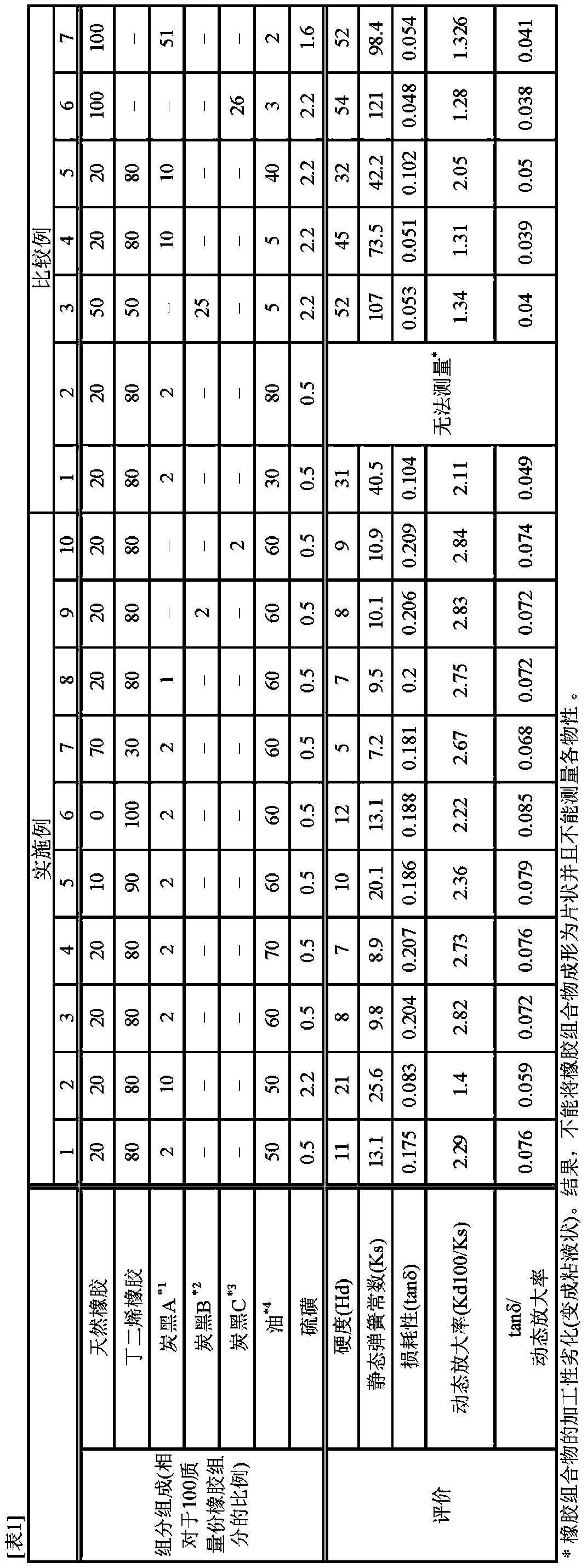

Embodiment 1 to 10 and comparative example 1 to 7

[0084] A rubber composition for anti-vibration rubber to be used as each sample was prepared according to the component composition listed in Table 1.

[0085] The rubber composition for anti-vibration rubber of each sample was heated at 155° C. for 30 minutes to 90 minutes to perform a vulcanization treatment, thereby preparing a sample of a crosslinked rubber composition for anti-vibration rubber.

[0086] (evaluate)

[0087] Each sample of the crosslinked rubber composition for vibration-proof rubber was evaluated in terms of (1) hardness, (2) static spring constant, (3) loss, and (4) dynamic amplification.

[0088] (1) Hardness (Hd)

[0089] The hardness of each sample of the vulcanized rubber composition for anti-vibration rubber was measured according to JIS K 6253 (type A). The measurement results are listed in Table 1.

[0090] For the measured hardness, the larger the value, the higher the hardness.

[0091] (2) Static spring constant (Ks)

[0092] The static sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com