Shell, manufacturing method thereof and electronic equipment

A shell and optional technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, ion implantation plating, etc., can solve the problems of easy peeling off of the appearance layer, weak bonding of the appearance layer, easy cracking and falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

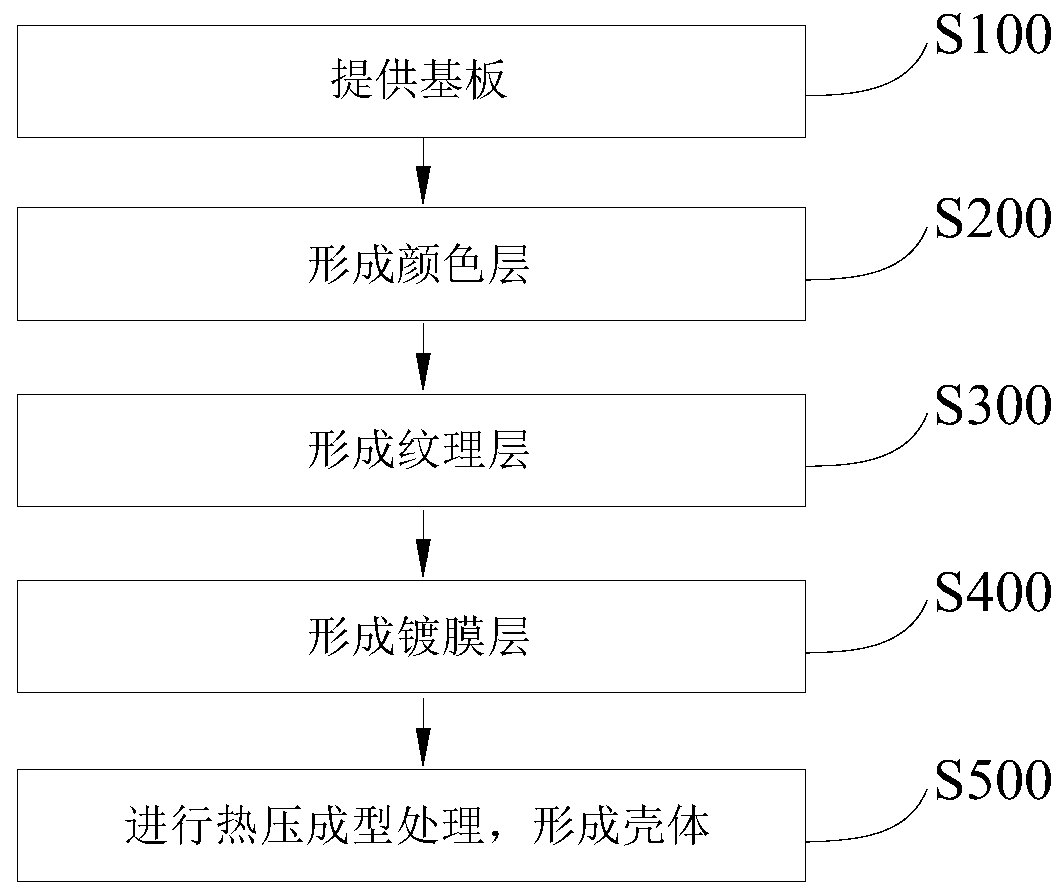

Method used

Image

Examples

example 1

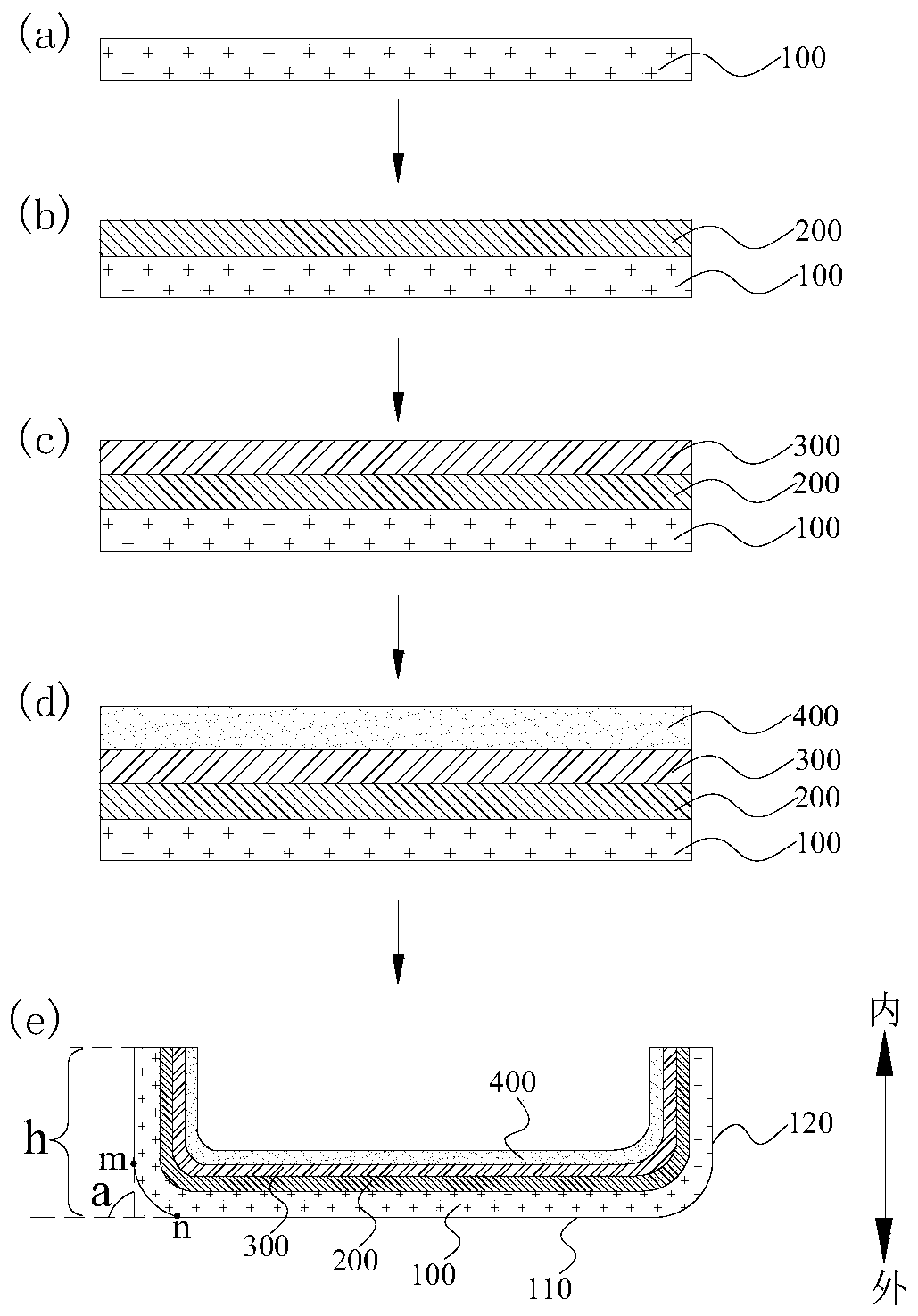

[0066] (1) A composite plate of PC and PMMA is used as the substrate, wherein the thickness of the PC layer is 0.59mm, and the thickness of the PMMA layer is 0.05mm, and the substrate is cut to a suitable size;

[0067] (2) Silk-screen mirror silver ink on the PC layer side of the substrate, the thickness of the mirror silver ink is 1-4 μm, and then bake to form the LOGO, the baking temperature is 60-80 ° C, and the baking time is 45-80 minutes;

[0068] (3) spray color ink on the side with LOGO on the substrate, and solidify, bake at 85-100°C for 20-120min to form a color layer, the elongation at break of the color layer is 120%;

[0069] (4) Transfer a layer of UV glue on the side of the color layer away from the substrate to form a texture layer. The thickness of the texture layer is 10μm, and the LED curing energy is 800-2500mj / cm when transferring 2 , and then mercury lamp curing energy 550-1500mj / cm 2 , the UV glue is polyurethane acrylate, the Shore hardness of the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com