Production method of solar cell

A technology of solar cells and production methods, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as poor filling uniformity of perovskite solutions, achieve uniform and stable filling effects, reduce randomness, and accelerate penetration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

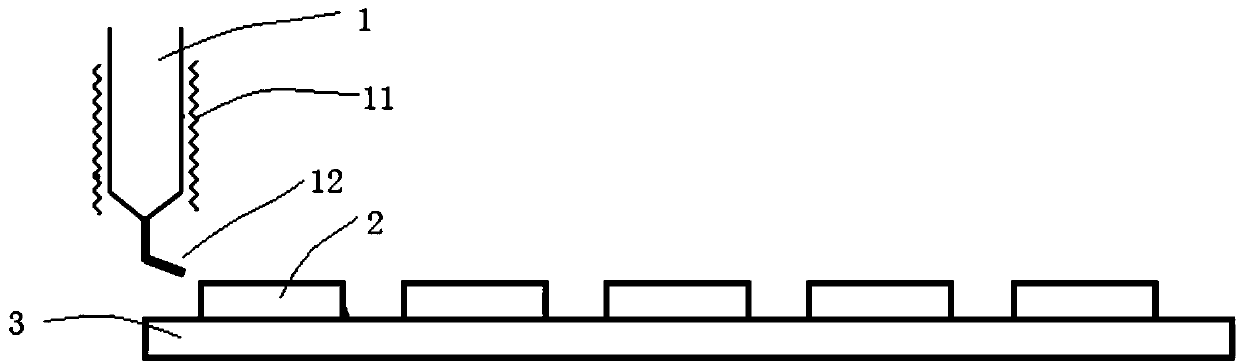

[0034] Such as figure 1 As shown, the perovskite precursor solution coating device has a liquid storage container 1, and a heating device 11 is arranged outside it, so as to heat and keep warm the perovskite precursor solution. A needle 12 for discharging the perovskite precursor solution is provided below the liquid storage container 1 . The solar cell body 2 is located below the needle head 12 , and a heating plate 3 is provided below several solar cell bodies 2 to provide a stable temperature environment for the solar cell body 2 .

[0035] A fluorine-doped tin oxide (FTO) conductive glass with a length of 100 mm and a width of 100 mm was laser etched into nine sub-cells connected in series. The conductive glass was ultrasonically cleaned with detergent, distilled water and absolute ethanol for 10 minutes in sequence. Place the cleaned conductive glass on the hot stage, and block the opposite electrode area with a shield. Heating to 450°C, spraying the ethanol solution o...

Embodiment 2

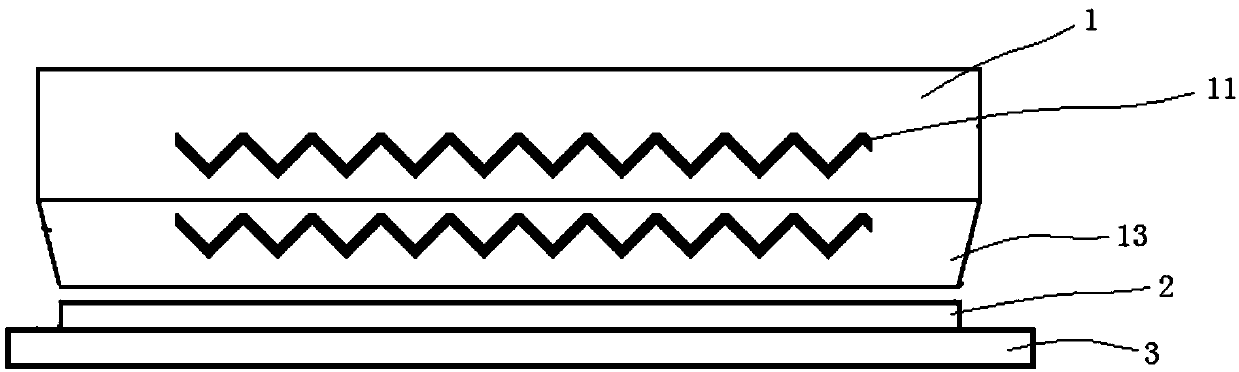

[0039] Such as figure 2 As shown, the perovskite precursor solution coating device has a liquid storage container 1, and a heating device 11 is arranged inside it, so as to heat and keep warm the perovskite precursor solution. Below the liquid storage container 1 is provided a slit cutter head 13 for discharging the perovskite precursor solution. The solar cell body 2 is located below the slit cutter head 13 , and a heating plate 3 is arranged below several solar cell bodies 2 to provide a stable temperature environment for the solar cell body 2 .

[0040] A fluorine-doped tin oxide (FTO) conductive glass with a length of 100 mm and a width of 100 mm was laser etched into nine sub-cells connected in series. The conductive glass was ultrasonically cleaned with detergent, distilled water and absolute ethanol for 10 minutes in sequence. Place the cleaned conductive glass on the hot stage, and block the opposite electrode area with a shield. Heating to 450°C, spraying the etha...

Embodiment 3

[0044]A fluorine-doped tin oxide (FTO) conductive glass with a length of 100 mm and a width of 100 mm was laser etched into nine sub-cells connected in series. The conductive glass was ultrasonically cleaned with detergent, distilled water and absolute ethanol for 10 minutes in sequence. Place the cleaned conductive glass on the hot stage, and block the opposite electrode area with a shield. Heating to 450°C, spraying the ethanol solution of diisopropyl di(acetylacetonate) titanate on the surface of the conductive glass, and decomposing it to form a dense layer of titanium dioxide. Remove the barrier of the counter electrode area, deposit nano-titanium dioxide with a thickness of 1.8 μm on the dense layer by screen printing technology, and sinter at 500 ° C for 1 hour to form a mesoporous titanium dioxide film. Cool the conductive glass, and then use screen printing technology to form a zirconia slurry with a thickness of 2 μm on the mesoporous titanium dioxide film, and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com