Radial plunger pump/motor and flow distribution structure thereof

A technology of plug pumps and motors, which is applied in the field of radial plug pumps/motors and their distribution structures. It can solve the problems of high design and processing requirements for distribution valves, delays in the opening and closing of distribution valves, and loss of volumetric efficiency, and improve friction and wear. and leakage problems, good sealing performance, and the effect of improving opening and closing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

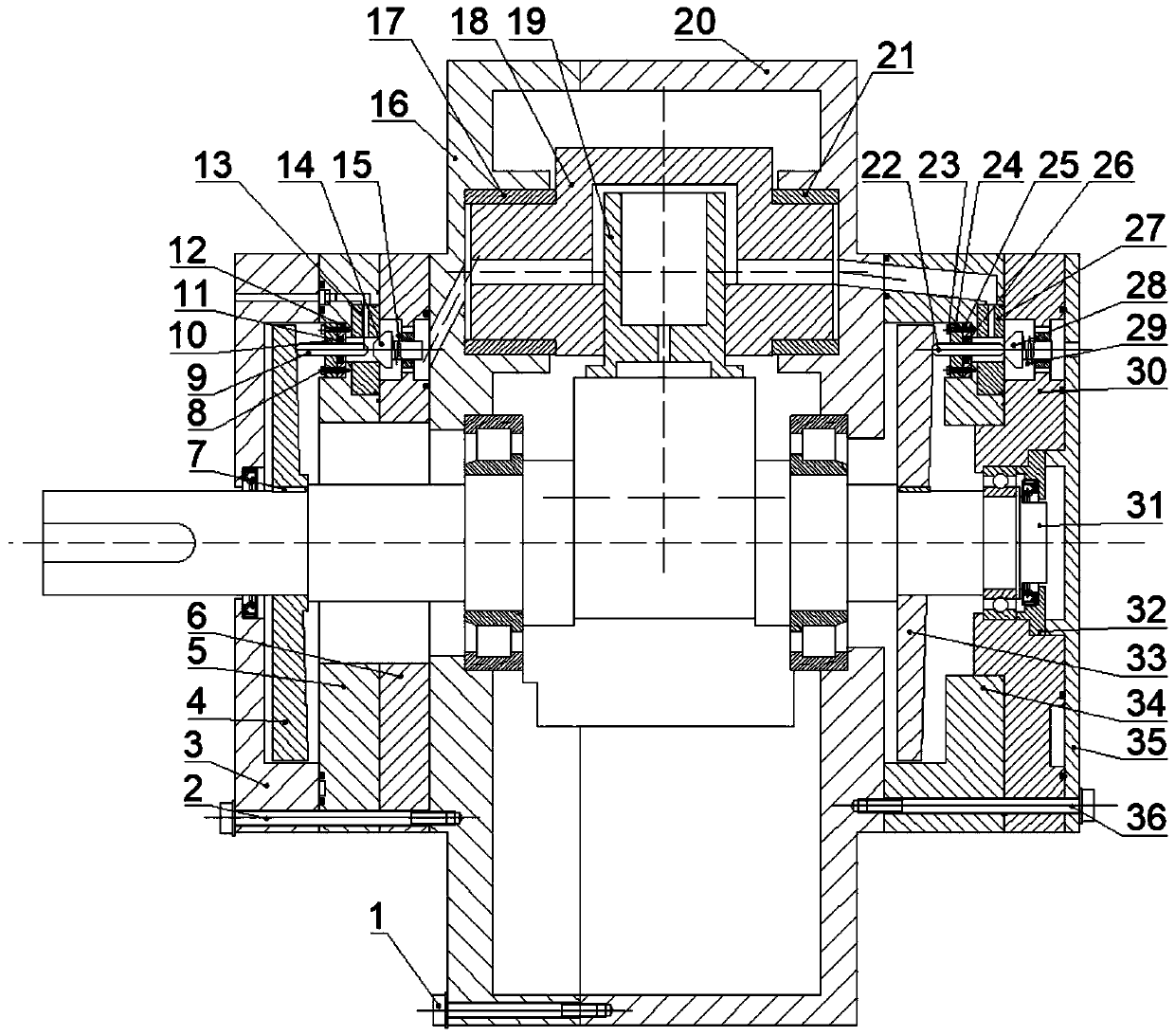

[0041] The present invention is described in further detail now in conjunction with accompanying drawing. These accompanying drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so only show the formation related to the present invention, and mainly carry out with the structure and working principle of this flow distribution structure applied to the swing cylinder type five-plunger motor Explanations, of course, are not limited to the specific structure of the swing-cylinder five-piston motor.

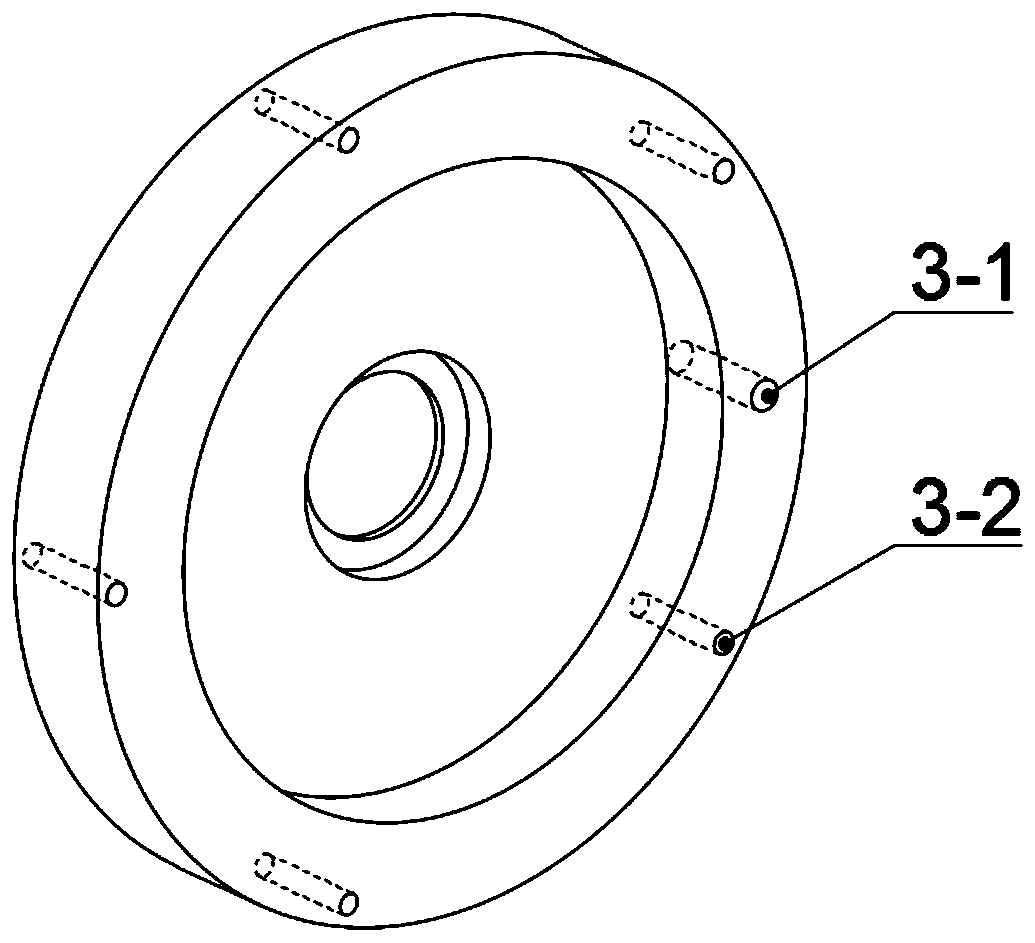

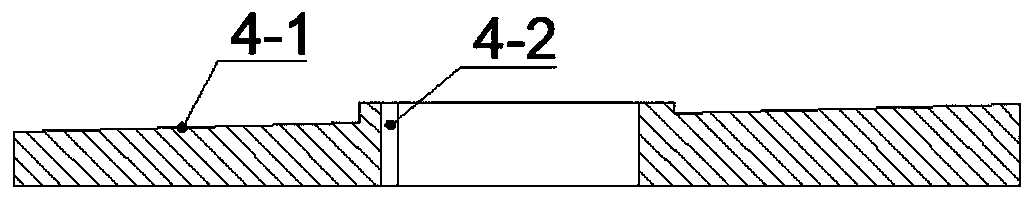

[0042] Such as figure 1As shown, the swing cylinder five-piston motor mainly includes a first end cover 3, a first pump / motor housing 16, a first swing cylinder sleeve 17, a swing cylinder 18, a plunger 19, a second pump / motor housing 20 , the second swing cylinder liner 21, the crankshaft 31, the second end cover 35; the plunger 19 is installed in the swing cylinder 18, and the two ends of the swing cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com