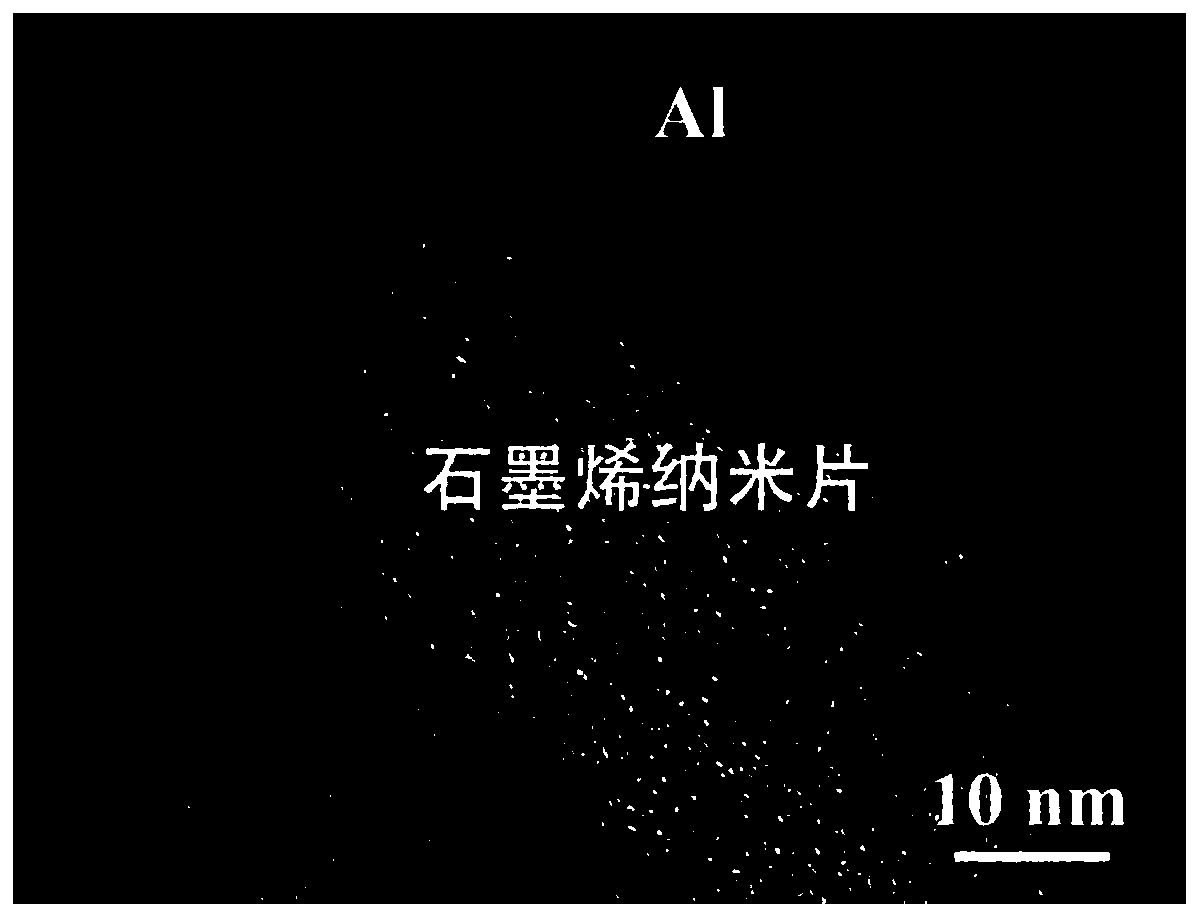

Graphene nanosheet/aluminum composite and preparation method thereof

A graphene nanosheet and aluminum composite material technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor reinforcement effect and low plasticity of graphene/aluminum composite materials, and avoid the pollution of aluminum powder. The effect of uniform dispersion and little structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The graphene nanosheet mass fraction described in this embodiment is the graphene nanosheet / aluminum composite material of 0.5% and preparation method thereof, and concrete steps are as follows:

[0033] 1) Get 5g graphene nanosheets, add in 1000ml dehydrated ethanol, first mechanically stir for 1h, the stirrer rotating speed is 700rpm, then ultrasonically disperse for 1h, the obtained concentration is the ethanol dispersion liquid of the graphene nanosheets of 0.5g / 100ml;

[0034] 2) Take 1200g of spherical aluminum powder and steel grinding balls and put them into a ball milling pot, vacuumize the ball milling pot, fill it with argon gas, and then ball mill. The speed of the ball mill is 400rpm, and the ball milling time is 3h to obtain flake aluminum powder;

[0035] 3) Open the ball mill tank in the glove box filled with argon, get 995g flake aluminum powder and move it into the ethanol dispersion of graphene nanosheets, and disperse the flake aluminum powder by mech...

Embodiment 2

[0040] The graphene nanosheet mass fraction described in the present embodiment is the graphene nanosheet / aluminum composite material of 1.0% and preparation method thereof, and concrete steps are as follows:

[0041] 1) Get 10g graphene nanosheets, add in 1000ml dehydrated ethanol, first mechanically stir for 1h, the stirrer rotating speed is 700rpm, then ultrasonic dispersion 2h, the obtained concentration is the ethanol dispersion liquid of the graphene nanosheets of 1.0g / 100ml;

[0042] 2) Take spherical aluminum powder and steel grinding balls of 1200g and 2400g respectively and put them into a ball milling jar, vacuumize the ball milling jar, fill it with argon gas, and then ball mill. The speed of the ball mill is 300rpm, and the ball milling time is 2h to obtain flake aluminum powder ;

[0043] 3) Open the ball mill tank in the glove box filled with argon, move 990g flake aluminum powder into the ethanol dispersion of graphene nanosheets, and disperse the flake aluminu...

Embodiment 3

[0048] The graphene nanosheet mass fraction described in the present embodiment is the graphene nanosheet / aluminum composite material of 1.5% and preparation method thereof, and concrete steps are as follows:

[0049] 1) Get 15g graphene nanosheets, add in 1500ml dehydrated ethanol, first mechanically stir for 1h, the stirrer rotating speed is 700rpm, then ultrasonic dispersion 2h, the obtained concentration is the ethanol dispersion liquid of the graphene nanosheets of 1.0g / 100ml;

[0050] 2) Take spherical aluminum powder and steel balls of 1200g and 3600g respectively and put them into a ball milling jar, vacuumize the ball milling jar, fill it with argon gas, and then ball mill. The speed of the ball mill is 200rpm, and the ball milling time is 1h to obtain flake aluminum powder ;

[0051] 3) Open the ball mill tank in the glove box filled with argon, get 985g flake aluminum powder and move it into the ethanol dispersion of graphene nanosheets, and disperse the flake alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com