Method for directly preparing iodine monochloride from iodine-containing salt

A technology of iodine monochloride and iodine salt, applied in the direction of interhalogen compounds, which can solve the problems of limited application range, increased transportation cost, high cost, etc., and achieve the effects of high product purity, reduced production cost, and improved reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

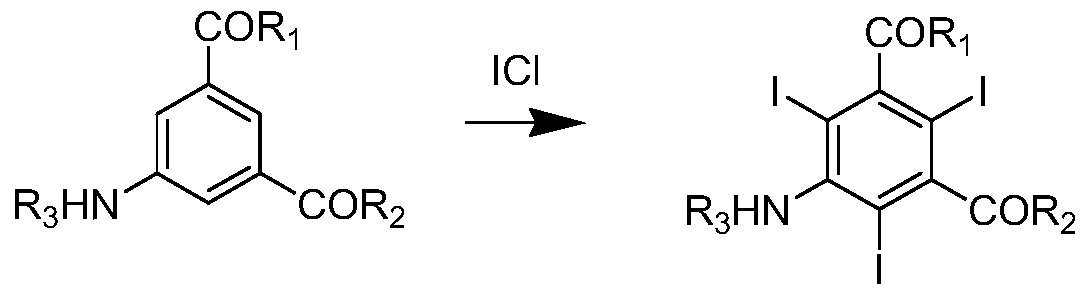

Image

Examples

Embodiment 1

[0022] (1) Put 50g of iodine-containing salt into a three-necked flask, fix it in an oil bath, connect the three-necked flask to a vacuum pump, turn on the vacuum pump to evacuate the three-necked flask to -0.1MPa, and heat the oil bath to 90°C , heat preservation and pressure holding for 4h, to obtain dry iodized salt;

[0023] (2) First lower the temperature of the oil bath to 40°C, then feed chlorine gas with a flow rate of 2g / h into the three-necked flask through the safety bottle, and maintain the pressure of the three-necked flask between 0.1MPa and 0.2MPa. The introduction of chlorine gas, potassium iodide gradually turns black, and changes from solid to liquid. When the amount of chlorine gas introduced reaches 70% of the stoichiometric amount, mechanical stirring is started. After the stoichiometric amount of chlorine gas is passed through, the stirring reaction is continued for 3 hours. After passing through the safety bottle and the concentrated sulfuric acid soluti...

Embodiment 2

[0028] (1) Add 1 kg of potassium iodide into the enamel reaction kettle and seal it, turn on the vacuum pump to evacuate the reaction kettle to -0.095MPa, turn on the heating mantle oil bath to heat the reaction kettle to 75°C, keep the temperature and pressure for 8 hours, and obtain dry potassium iodide ;

[0029] (2) First reduce the temperature of the reactor to 50°C, then feed chlorine gas with a flow rate of 50g / h into the reactor, and maintain the pressure of the reactor between 0.1MPa and 0.2MPa. When 75% of the stoichiometric amount, turn on the mechanical stirring. After the stoichiometric amount of chlorine gas is ventilated, continue to stir the reaction for 4h. After the reaction, the residual chlorine gas is passed into the NaOH aqueous solution with a mass fraction of 10%. The materials in the reaction kettle were transferred to an enamel filter and injected with nitrogen until the pressure was 0.1MPa-0.2MPa, and 735.4g of iodine monochloride was obtained by fil...

Embodiment 3

[0032] On the basis of embodiment 2, in embodiment 2 steps (1), 1kg potassium iodide is replaced into 5kg potassium iodide (its iodine content is 58.6wt% after analyzing) that reclaims from workshop, and pass into the chlorine gas in step (2) The flow rate was changed to 220g / h and the stirring reaction was continued for 6h after passing through the chlorine gas. Other conditions and steps were the same as in Example 2, and 3539.1g iodine monochloride was obtained by filtration.

[0033] The purity of the prepared iodine monochloride is 99.0wt% by titration with sodium thiosulfate standard solution, and the yield of iodine monochloride is 93.4% through weighing calculation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com