Manufacturing method of lightweight connecting rod with rubber-metal ball joint

A rubber metal and manufacturing method technology, applied in the coating and other directions, can solve the problems of poor stress condition, complex structure, inconvenient production, etc., and achieve the effect of improving the bearing capacity, simplifying the installation process, and avoiding weak position strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

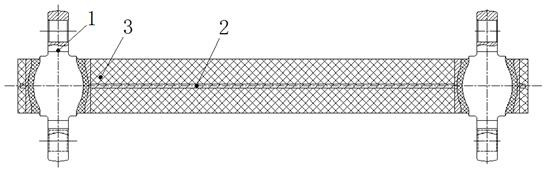

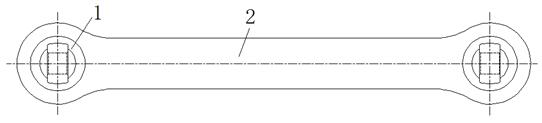

[0039] by attaching Figure 1-4 It can be seen that the present invention relates to a method for making a lightweight connecting rod with a rubber-metal spherical hinge. First, the rubber-metal spherical hinge 1 and the reinforcing body 2 are respectively made, and then the rubber-metal spherical hinge 1 is put into the reinforcing body 2, and the Make the outer shell 5 of the rubber metal ball hinge embedded in the ball hinge hole 4 in the reinforcement body 2, and then put the reinforcement body 2 embedded with the rubber metal ball hinge 1 into the molding die 6, and the lightweight high The molecular material is wrapped around the outer shell of the rubber-metal spherical hinge and the reinforcement to form a lightweight connecting rod base 3, thereby forming a lightweight connecting rod with a rubber-metal spherical hinge. The specific production method is as follows:

[0040] 1) Make the rubber-metal spherical hinge and the reinforcing body respectively; wherein, the m...

Embodiment 2

[0054] The principle of the second embodiment is the same as that of the first embodiment, except that the structure is slightly different. The described method for making a lightweight connecting rod with a rubber-metal spherical hinge firstly manufactures the rubber-metal spherical hinge and the reinforcing body, respectively. Then put the rubber metal ball hinge into the reinforcement body, and make the outer shell of the rubber metal ball hinge embedded in the ball hinge hole in the reinforcement body, and then put the reinforcement body embedded with the rubber metal ball hinge into the forming mold, and through the molding process. In this way, the lightweight polymer material is wrapped around the outer casing of the rubber-metal spherical hinge and the reinforcement to form a lightweight connecting rod with the rubber-metal spherical hinge.

[0055] The specific production method is as follows:

[0056] 1) The rubber-metal spherical hinge and the reinforcing body are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com