A Method of Filling Welding Keyhole Using Stir Friction

A friction stir and keyhole technology, used in the filling of keyholes, using friction stir to fill the welding keyhole field, can solve the problems of difficult process, long time, tunnel holes, etc., to simplify system control, avoid extraction process, reduce The effect of process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is applied to the filling of welding keyholes of aluminum alloy automobile wheel hubs welded by friction stir welding.

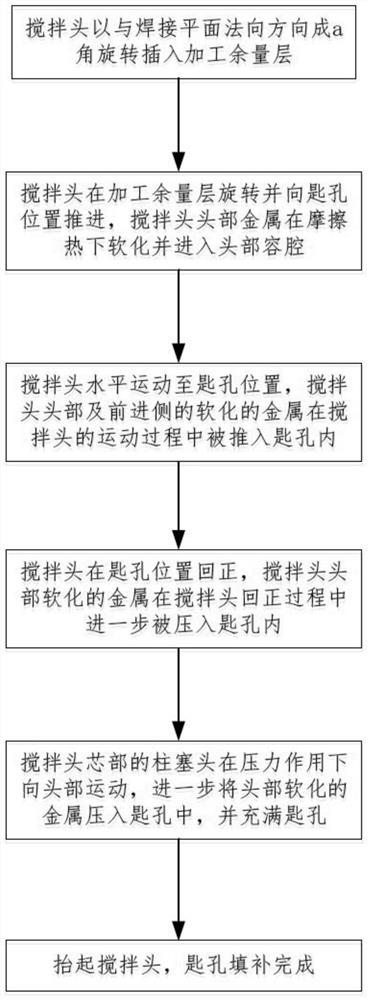

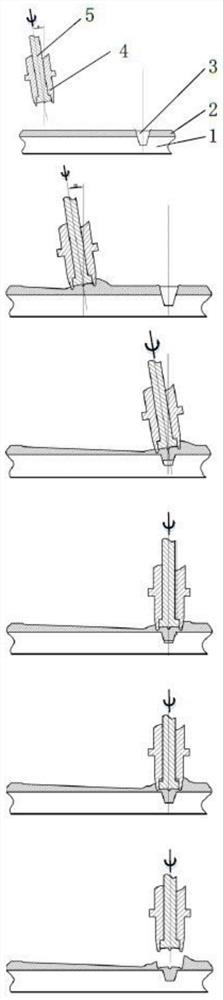

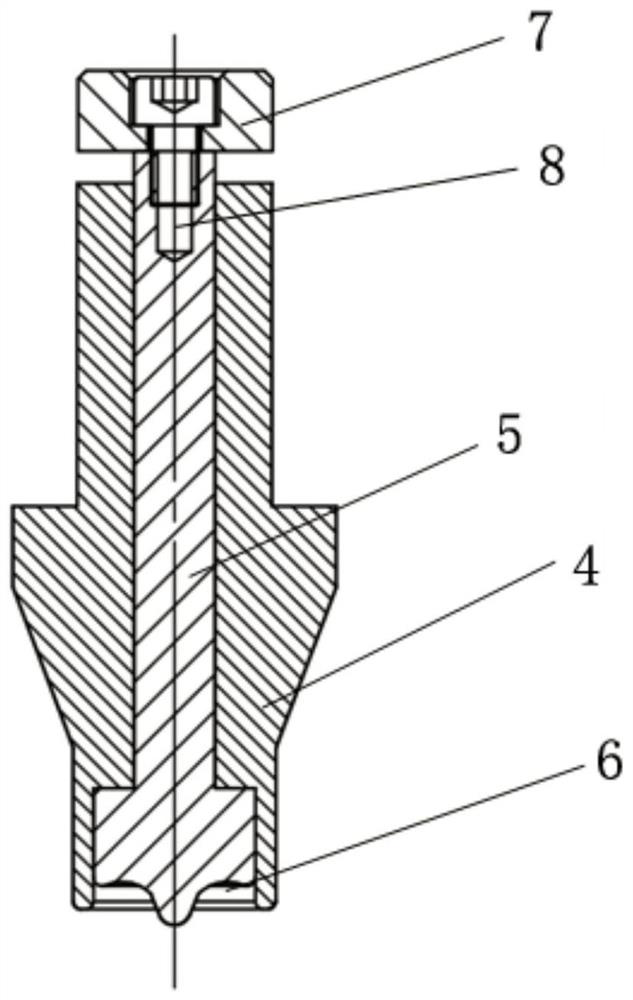

[0041] The wheel hub uses friction stir welding to weld the spokes and the hub together. After welding, the machining allowance layer of the machining is 3mm on one side, and the weld seam is a circular closed weld seam. When the welding head leaves the weld seam, a 8.5mm gap is left on the weld seam. Deep welded keyhole. For the keyhole, a rotating stirring head is inserted obliquely into the machining allowance layer of the hub at an inclination angle of 3 degrees. The rotating speed of the stirring head is 1600r / min, the moving speed is 200mm / min, and the moving distance of the stirring head is 60mm. During the process of the rotating stirring head moving to the keyhole position in the machining allowance layer of the hub, the allowance material at the front of the stirring head is softened due to frictional heat, and the softened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com