Ball milling device and ball milling system thereof

A technology of ball milling and mesh, which is applied in the field of mechanical processing, can solve problems such as difficult crushing and handling, and achieve the effects of easy maintenance, advanced manufacturing technology, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

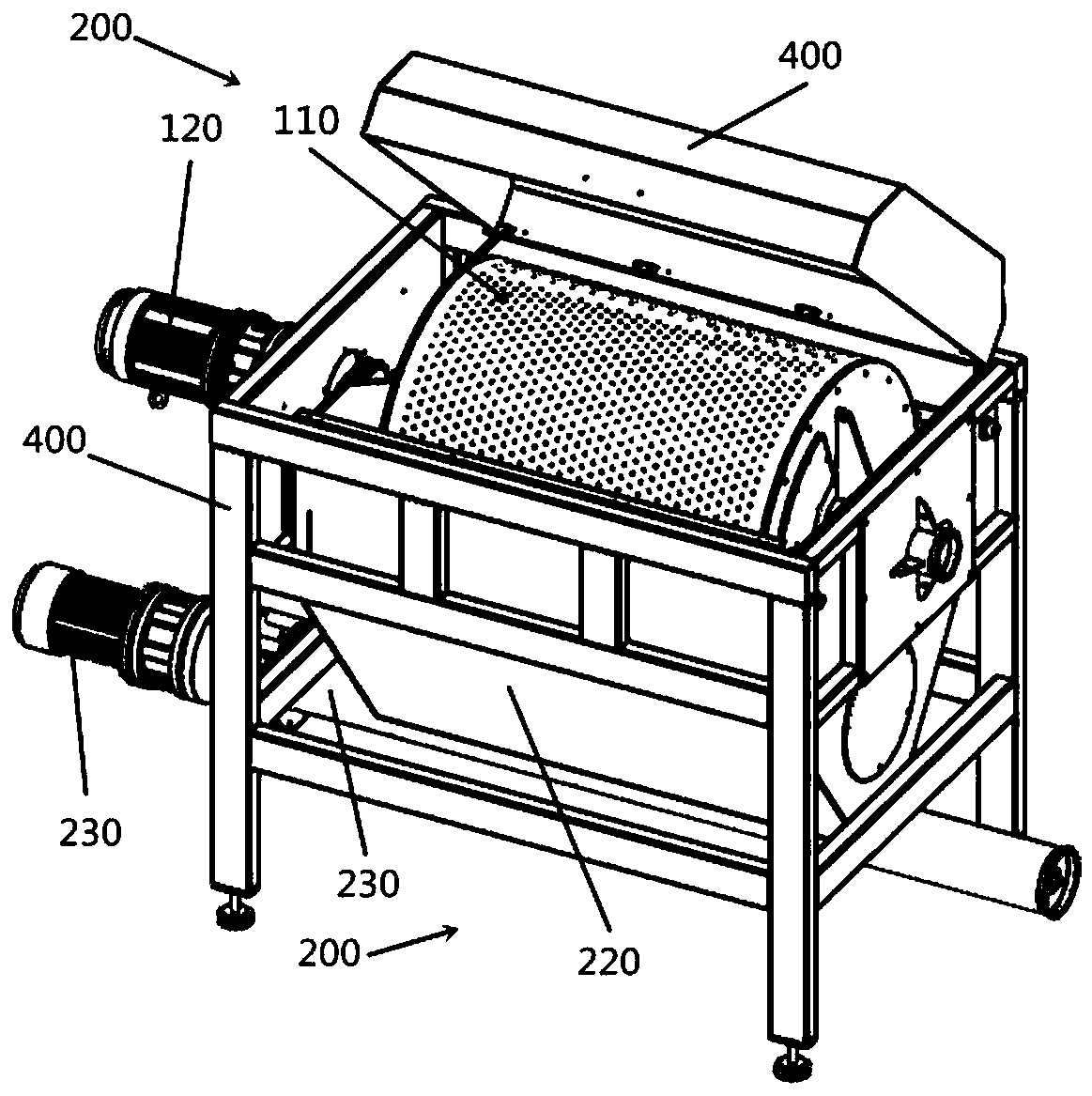

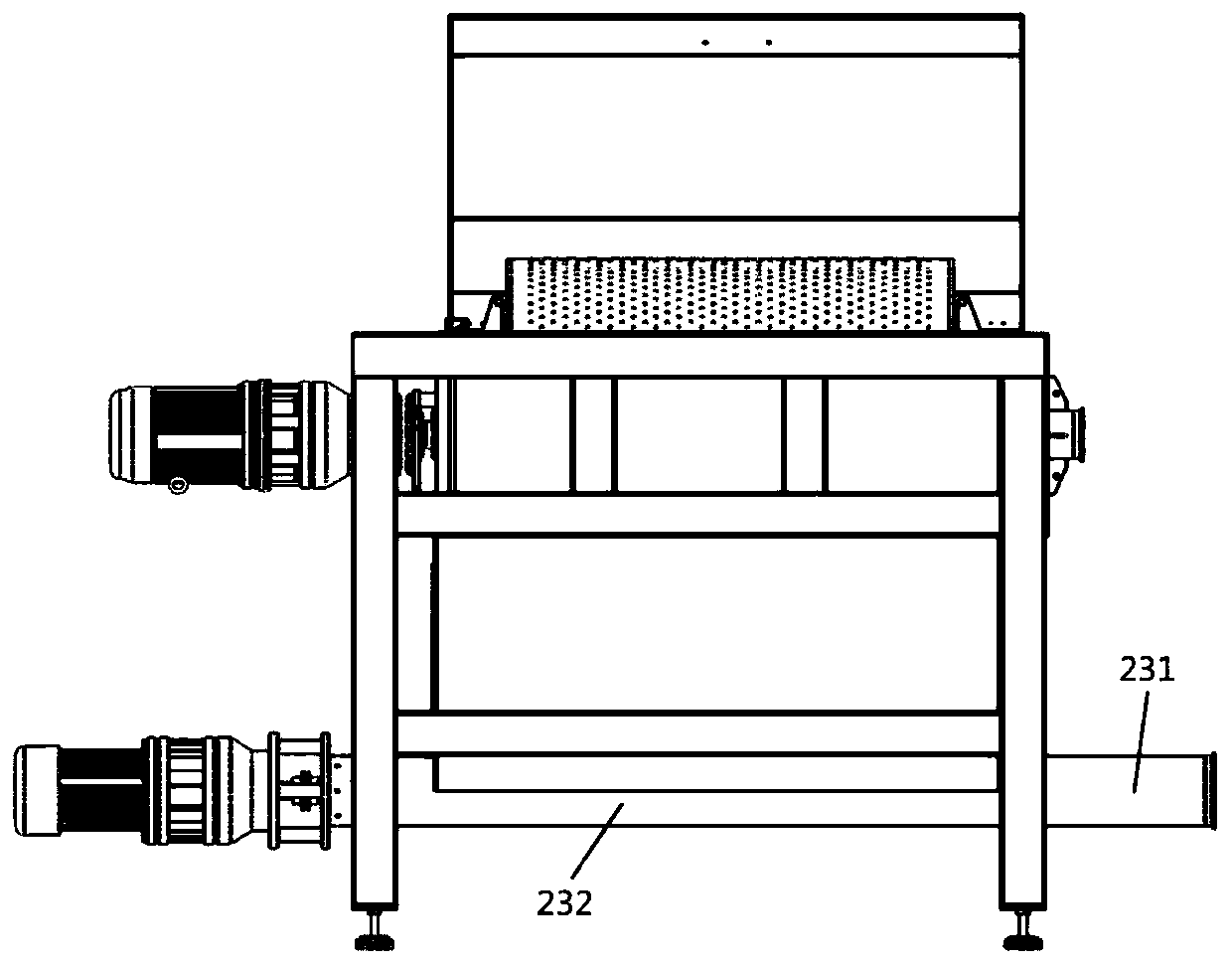

[0029] refer to figure 1 , a ball milling system, including a frame 300, the frame 300 is composed of multiple brackets, the bracket includes a frame that plays a supporting role and a frame that plays a space isolation role, and the isolation of the frame in the vertical direction Two parts are formed, that is, the ball milling space and the material receiving space. In this embodiment, the ball milling space is used to place the ball milling equipment and the ball milling device, and the material receiving space is used to place the material receiving equipment, that is, the material receiving device.

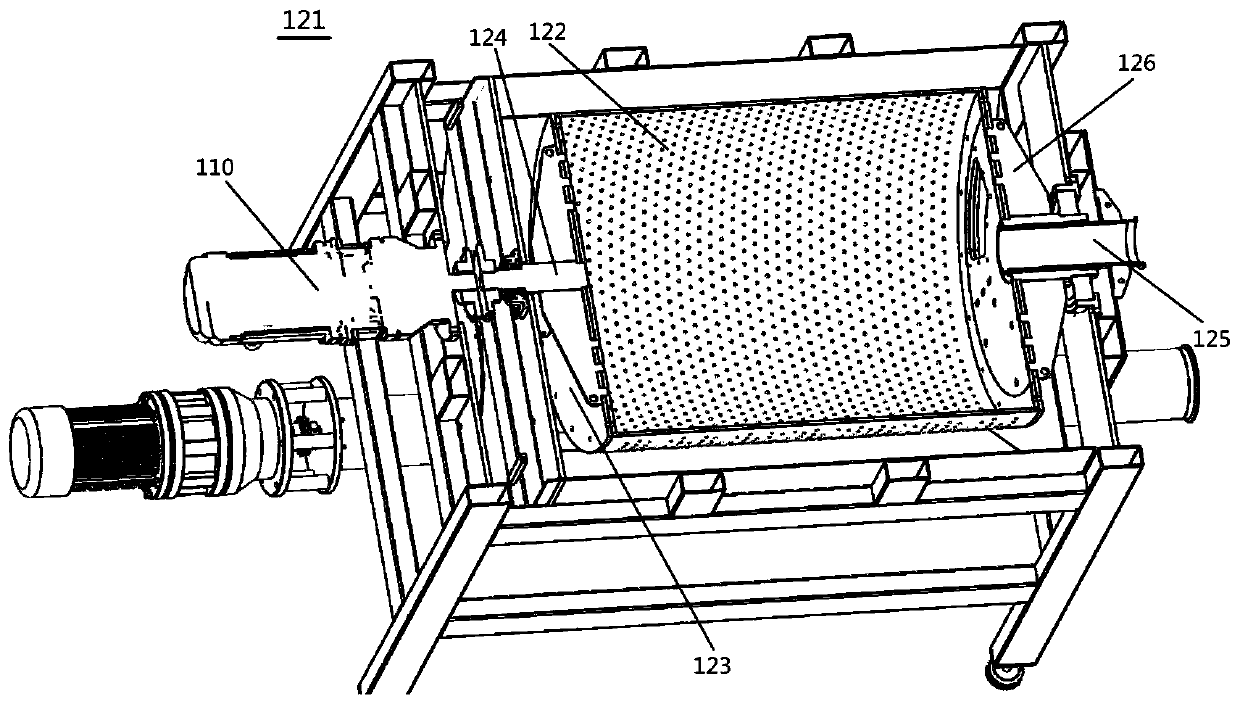

[0030] In this embodiment, the ball milling device has a ball milling part 100 , and the material receiving device includes a material receiving part 200 . Wherein, the ball milling part 100 and the material receiving part 200 are provided correspondingly, that is, the material receiving part 200 is used to receive the material after ball milling by the ball milling part 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com