Dual hand robot for track link trimming and automating process using same

A technology of robots and crawler chains, applied in manipulators, manufacturing tools, metal processing equipment, etc., can solve problems such as low productivity, high accident rate of staff, and reduced productivity, and achieve stable processing, reduce production costs, and reduce production times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, specific contents for implementing the present invention will be described with reference to the drawings. Also, for describing the present invention, when it is judged that related known functions are obvious to those of ordinary skill in the art and would obscure the gist of the present invention, detailed description thereof will be omitted.

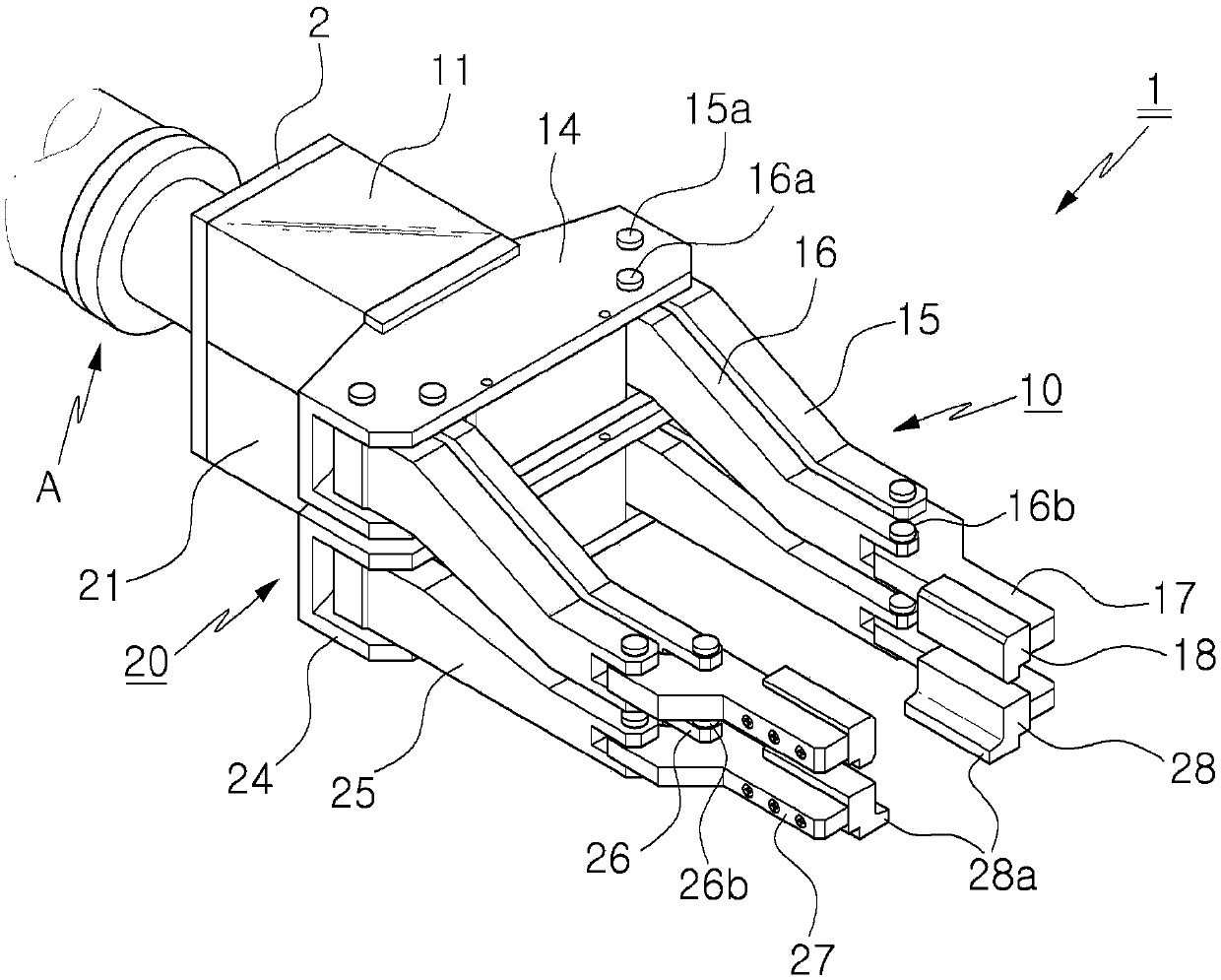

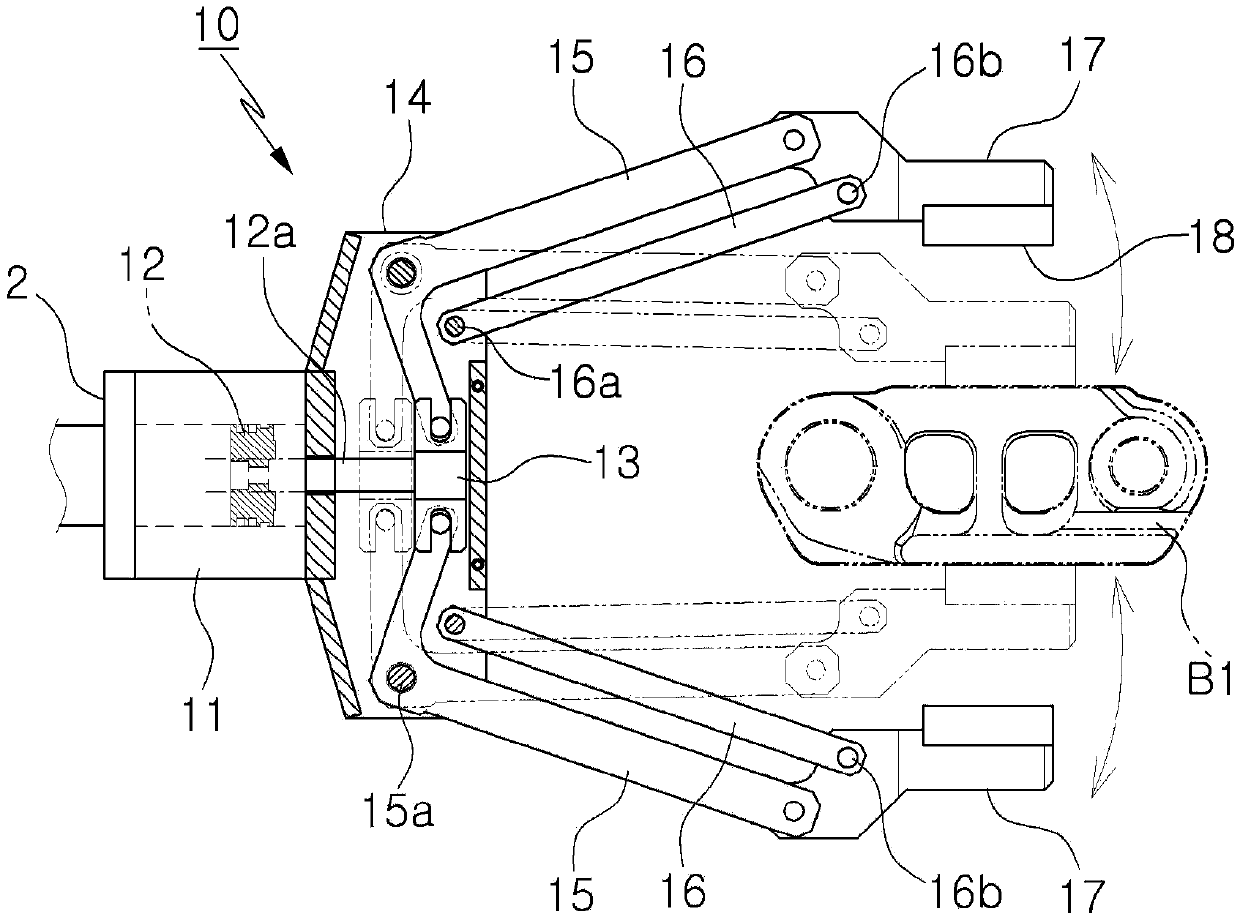

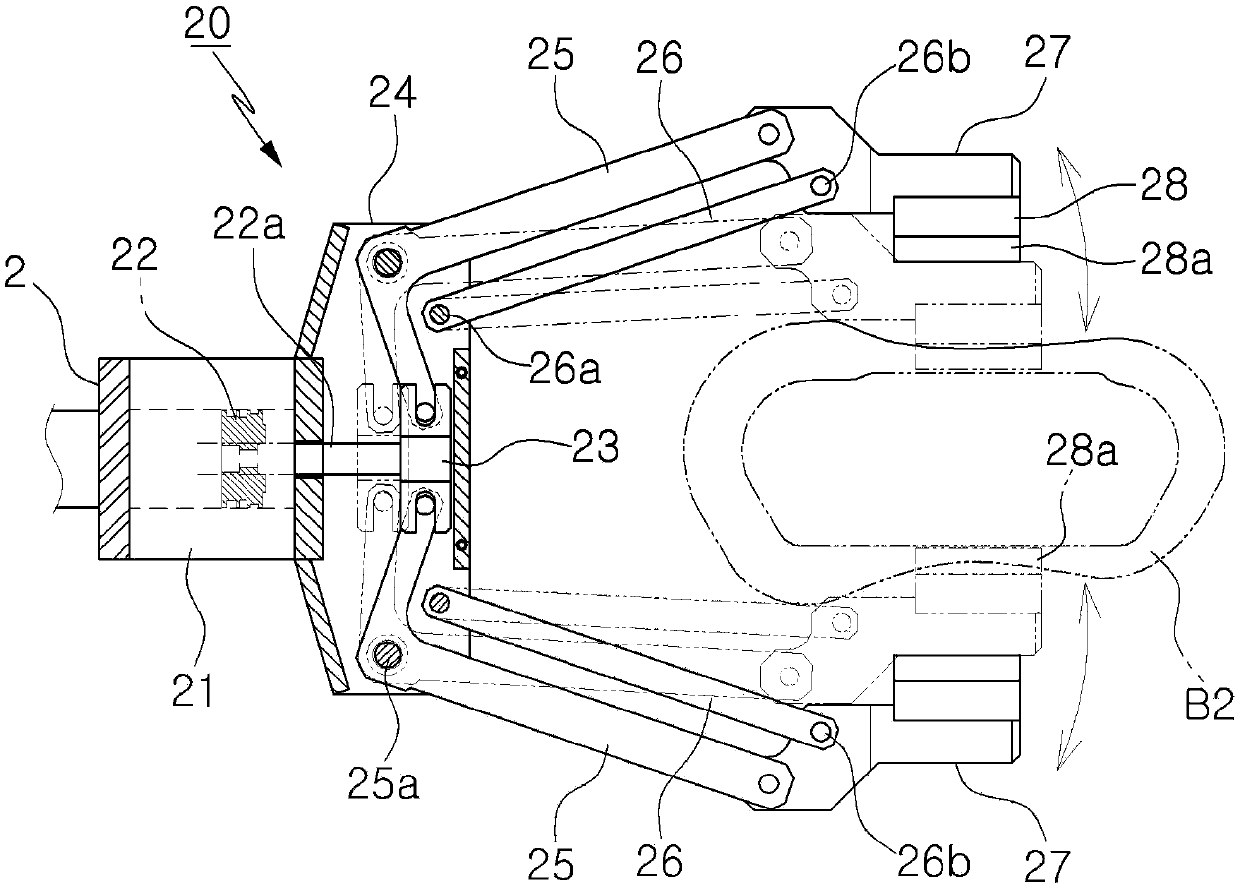

[0033] figure 1 In order to show a perspective view of a preferred embodiment of the two-handed robot for crawler chain trimming provided by the present invention, figure 2 , image 3 It is a longitudinal sectional view showing the operating state of the first manipulator robot and the second manipulator robot of the present invention.

[0034] Such as figure 1 As shown, in the present invention, a two-handed robot 1 is provided at the end of the arm of a transport robot A used for transporting materials or products in a forging production line. Arm end; the first manipulator 10 is arranged on the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com