Bristle-like chemical fiber filament brushing bristle

A technology of chemical filaments and bristles, applied in the field of brush processing, can solve the problems of unsuitable cleaning, paint loss, time-consuming and labor-intensive, etc., and achieve the effects of shortening the paint absorption time, increasing the amount of paint absorption, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of bristle-like chemical fiber bristles, which are composed of chemical fiber filaments of the following specifications with the same length:

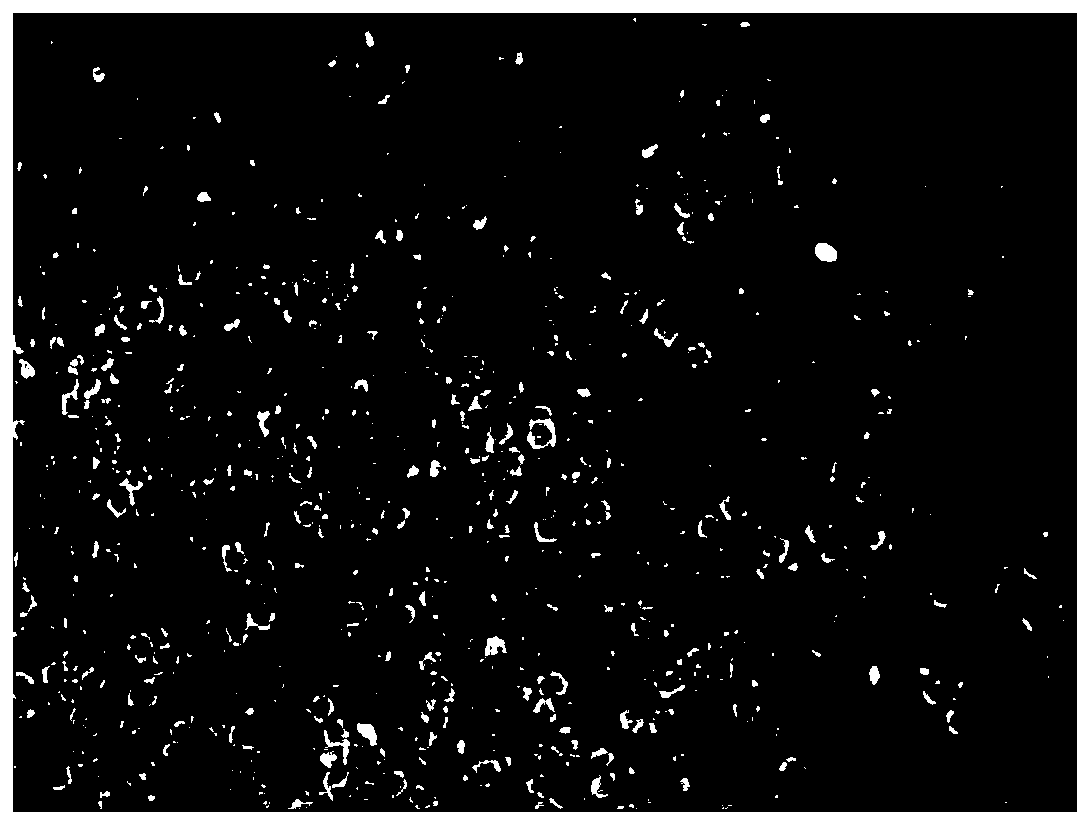

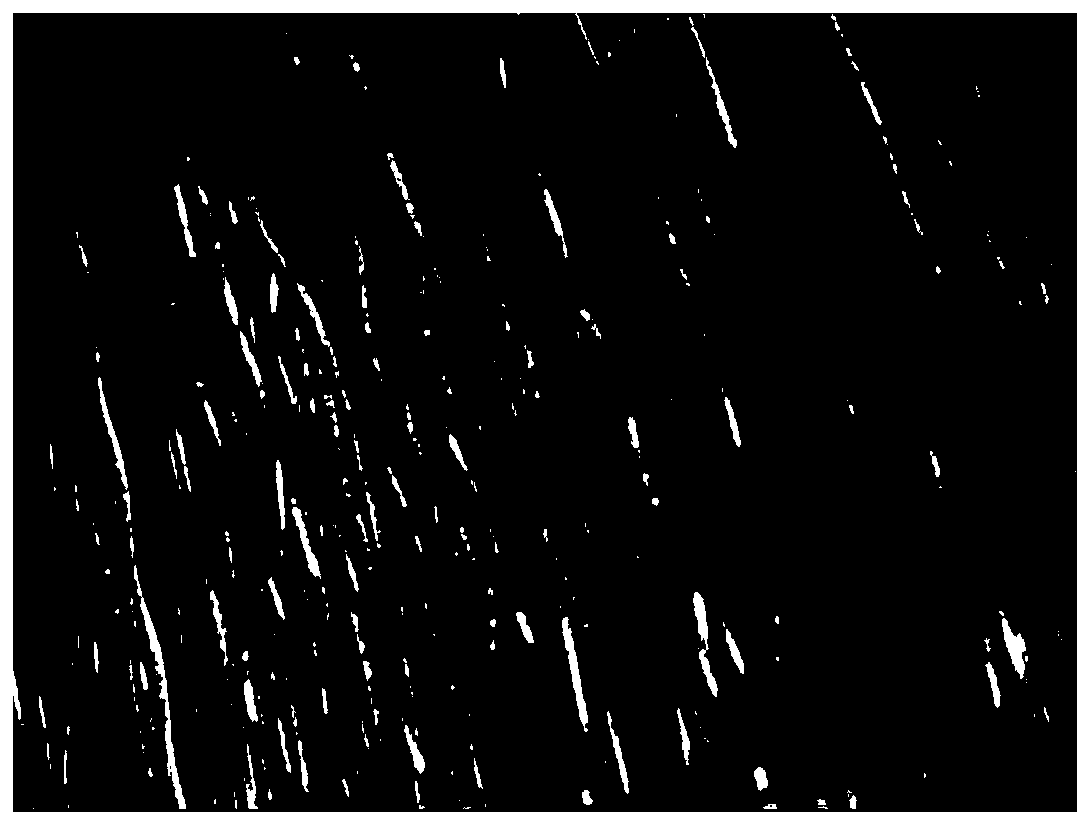

[0030] 20% of solid sharpened chemical filaments with a diameter of 0.16mm, 30% of hollow sharpened chemical filaments with a diameter of 0.16mm, 30% of corrugated chemical filaments with a diameter of 0.20mm, 10% of triangular chemical filaments with a diameter of 0.20mm, with a diameter of 0.18mm cross chemical filament 10%. Wherein the hollow diameter of the hollow sharpened chemical fiber is 0.04-0.07mm. Microscopic photos of the above five kinds of chemical fibers are as follows: Figure 1-5 shown.

[0031] The solid sharpened chemical fiber, hollow sharpened chemical fiber, corrugated chemical fiber, triangular chemical fiber, and cross chemical fiber are mixed evenly in proportion, and then neatly arranged and bundled into a bundle to form bristle-like chemical fiber bristles.

Embodiment 2

[0033] A kind of bristle-like chemical fiber bristles, which are composed of chemical fiber filaments of the following specifications with the same length:

[0034] 15% of solid sharpened chemical filaments with a diameter of 0.17mm, 25% of hollow sharpened chemical filaments with a diameter of 0.18mm, 35% of corrugated chemical filaments with a diameter of 0.19mm, 15% of triangular chemical filaments with a diameter of 0.19mm, with a diameter of 0.17mm cross fiber 10%. Wherein the hollow diameter of the hollow sharpened chemical fiber is 0.04-0.07mm.

[0035] The solid sharpened chemical fiber, hollow sharpened chemical fiber, corrugated chemical fiber, triangular chemical fiber, and cross chemical fiber are mixed evenly in proportion, and then neatly arranged and bundled into a bundle to form bristle-like chemical fiber bristles.

Embodiment 3

[0037] A kind of bristle-like chemical fiber bristles, which are composed of chemical fiber filaments of the following specifications with the same length:

[0038] 10% of solid sharpened chemical filaments with a diameter of 0.16mm, 30% of hollow sharpened chemical filaments with a diameter of 0.17mm, 30% of corrugated chemical filaments with a diameter of 0.21mm, 15% of triangular chemical filaments with a diameter of 0.19mm, with a diameter of 0.18mm cross chemical filament 15%. Wherein the hollow diameter of the hollow sharpened chemical fiber is 0.04-0.07mm.

[0039] The solid sharpened chemical fiber, hollow sharpened chemical fiber, corrugated chemical fiber, triangular chemical fiber, and cross chemical fiber are mixed evenly in proportion, and then neatly arranged and bundled into a bundle to form bristle-like chemical fiber bristles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com