Manufacturing method of organic el display

A manufacturing method and display technology, applied in semiconductor/solid-state device manufacturing, instruments, electric solid-state devices, etc., can solve the problems of reducing the thickness of stretched films and not being able to obtain enough thin sheets, and achieve the effect of enhancing thinning and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

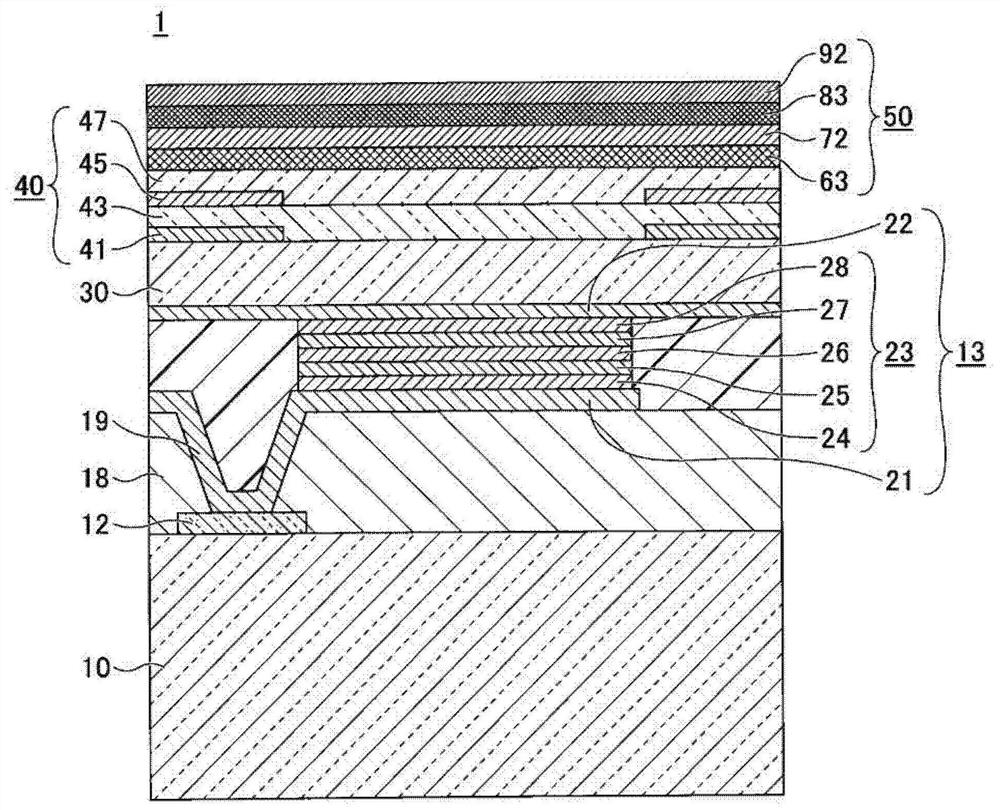

[0054] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings. In each drawing, the same or corresponding reference numerals are assigned to the same or corresponding structures, and description thereof will be omitted.

[0055]

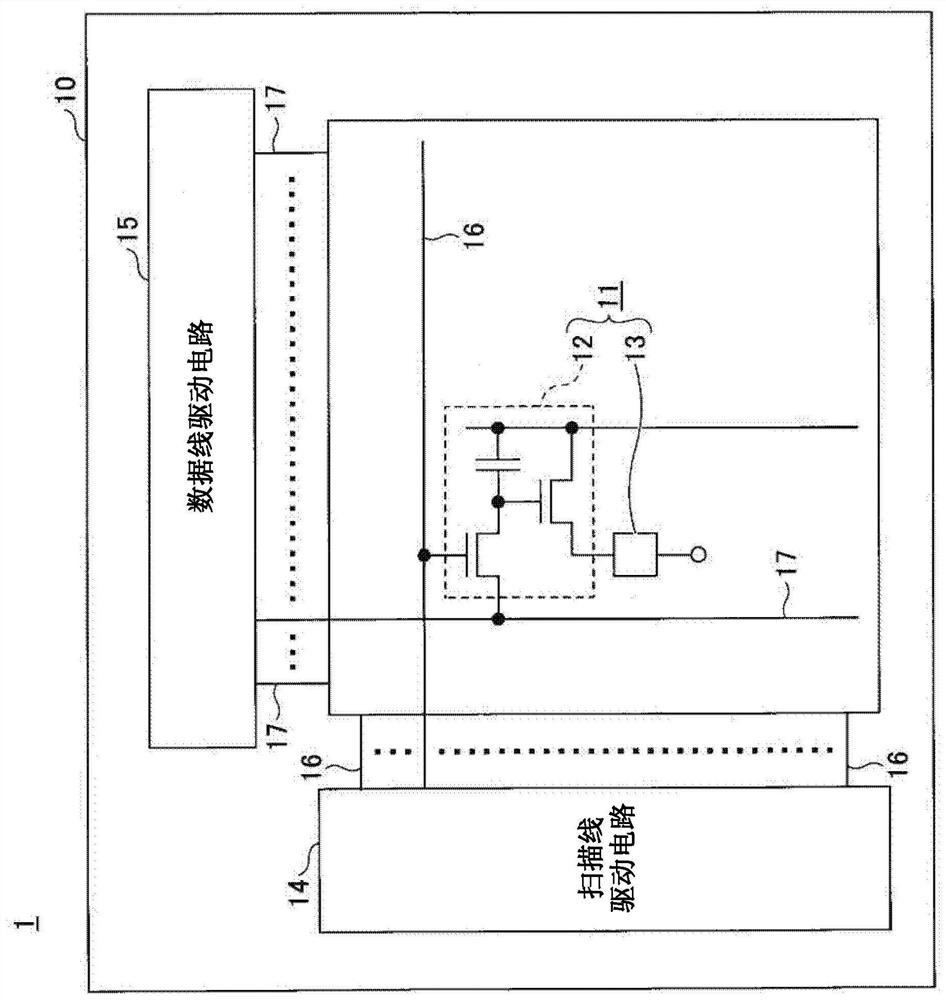

[0056] figure 1 It is a top view showing an organic EL display according to one embodiment. exist figure 1 In , the circuit of one unit circuit 11 is enlarged and shown.

[0057] The organic EL display 1 includes a substrate 10 , a plurality of unit circuits 11 arranged on the substrate 10 , a scanning line driving circuit 14 disposed on the substrate 10 , and a data line driving circuit 15 disposed on the substrate 10 . The unit circuit 11 is provided in an area surrounded by a plurality of scanning lines 16 connected to the scanning line driving circuit 14 and a plurality of data lines 17 connected to the data line driving circuit 15 . The unit circuit 11 includes a TFT layer 12 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com