Conveyor device and method for conveying shipments

A technology of conveying equipment and conveying parts, which is applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., and can solve the problems of low acceleration, time-consuming, and flow reduction of light goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

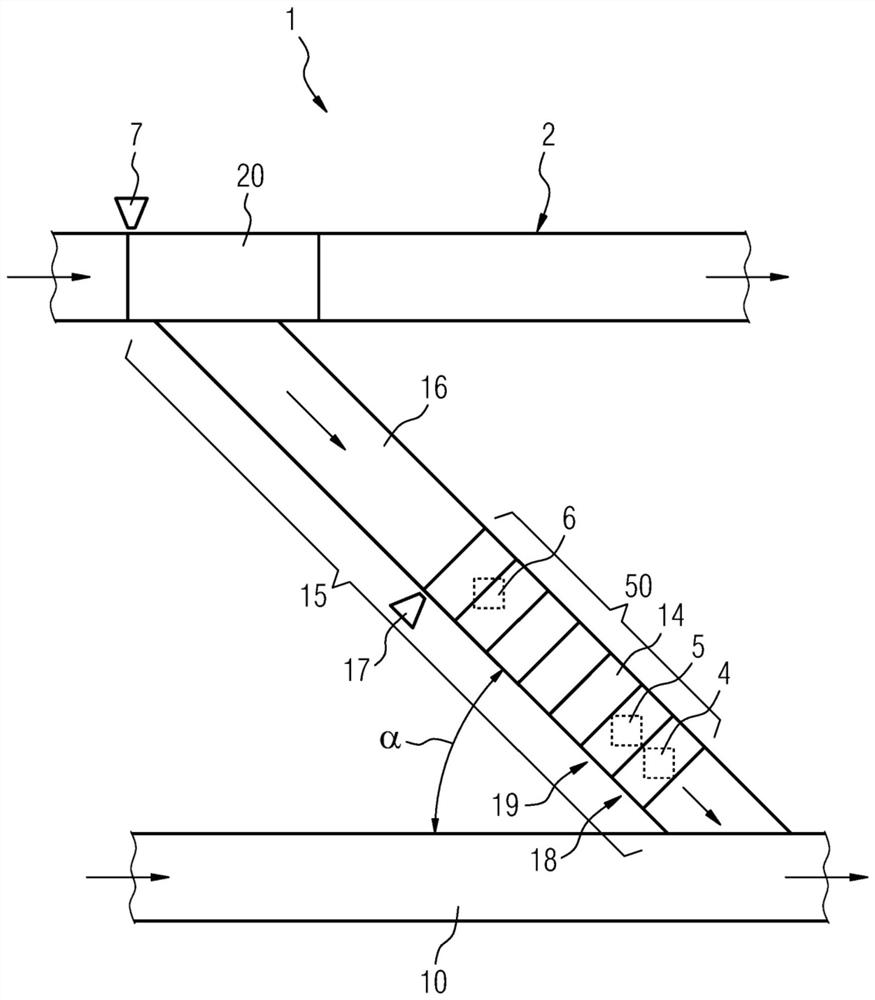

[0018] exist figure 1 A conveying device 1 according to the invention is shown in . The conveying device 1 here includes a conveying unit 2 which is designed for conveying item goods. The items 4 , 5 , 6 are transported, for example, by the transport unit 2 at a specific first transport speed. The conveying unit 2 is, for example, a conveying line, in which, for example, a plurality of different types of goods 4 , 5 , 6 are conveyed. The item goods 4 , 5 , 6 are conveyed on the conveying unit 2 in the direction of the arrows, for example. Furthermore, the transfer device 1 comprises a sorting unit 10 .

[0019] The respective items 4 , 5 , 6 are to be received and sorted from the conveyor unit 2 into the sorting unit 10 . The sorting unit 10 has, for example, a second conveying speed, wherein the conveying likewise takes place in the direction of the arrow purely by way of example. For this purpose, the sorting unit 10 provides a plurality of positions. For example, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com