Proton exchange membrane fuel cell combined heat and power system

A proton exchange membrane, fuel cell technology, applied in fuel cells, fuel cell additives, heating systems, etc., to achieve the system's environmental friendliness, good economy and market potential, and reduce peak loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

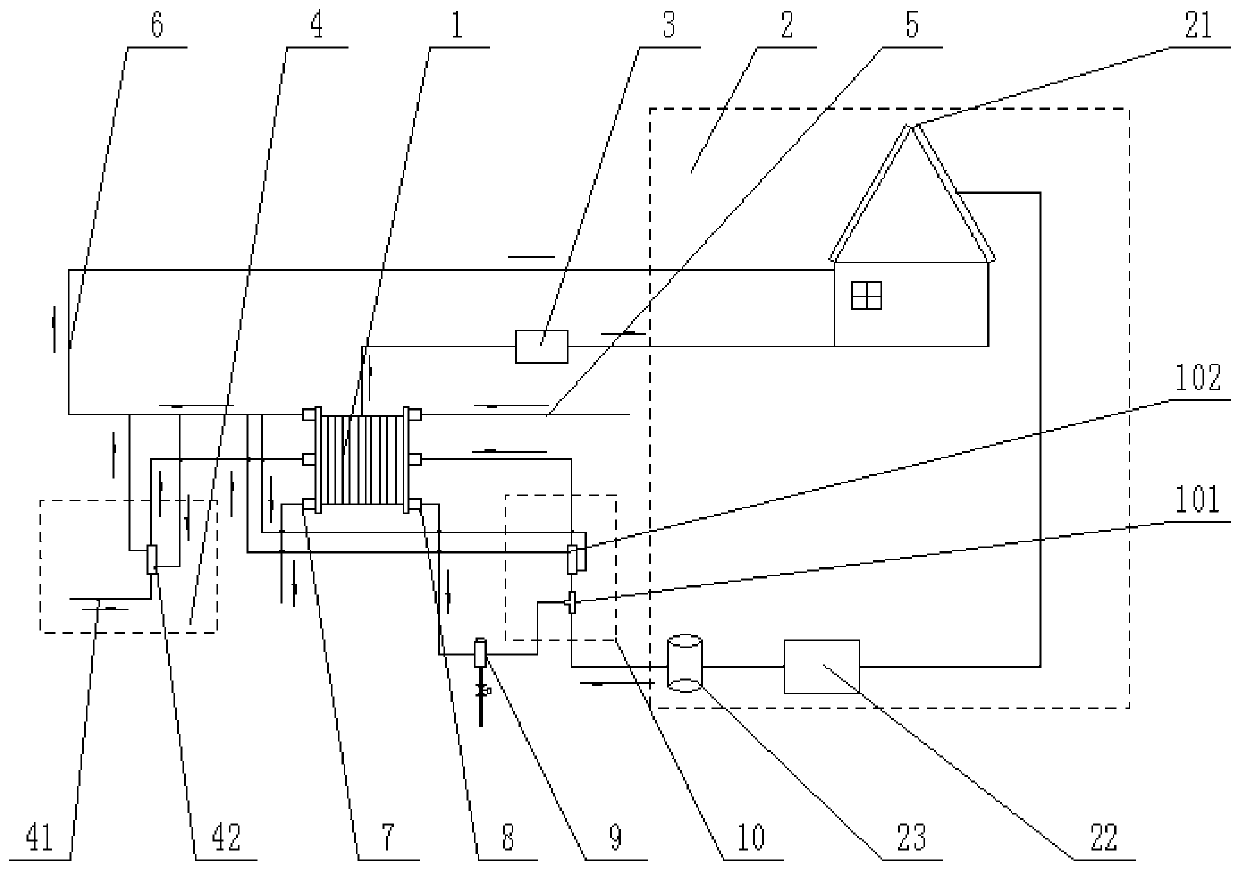

[0016] Example 1: Combining figure 1 Describe this embodiment, a proton exchange membrane fuel cell combined heat and power system, including: stack 1, hydrogen production device 2, power converter 3, air humidifier 4, cooling water pipe 5, heat supply pipeline 6, air exhaust Port 7, hydrogen outlet 8, gas-water separator 9 and injection humidification device 10, the cooling water inlet of the electric stack 1 is connected with a cooling water pipe 5, and the cooling water enters the electric stack 1 through the cooling water pipe 5, and the outlet of the electric stack 1 The water port provides heating for the user through the heating pipeline 6, the air humidifier 4 injects air into the cathode end of the cell stack 1 through the pipeline, the hydrogen production device 2 is connected with the injection humidification device 10 through the pipeline, and the injection humidification device 10 supplies air to the battery. The anode end of stack 1 is injected with hydrogen, the...

Embodiment 2

[0017] Embodiment 2: This embodiment is described in conjunction with Embodiment 1. The hydrogen production device 2 includes a solar plate 21, a water electrolyzer 22 and a hydrogen buffer tank 23. The solar plate 21 is connected to the water electrolyzer 22 through a line, and the water electrolyzer 22 The gas outlet of the hydrogen buffer tank 23 is connected to the gas inlet of the hydrogen buffer tank 23 through a pipeline, and the gas outlet of the hydrogen buffer tank 23 is connected to the injection humidification device 10 through a pipeline, and the hydrogen generated by the electrolysis of water is pressed into the hydrogen buffer tank 23 through a hydrogen compressor , both ends of the hydrogen buffer tank 23 are provided with valves and pressure gauges at the inlet and outlet. In this way, solar photoelectric electrolysis of water is used to produce hydrogen during the day, and the hydrogen is stored in the hydrogen buffer tank 23. At night, the peak power consumpti...

Embodiment 3

[0018] Embodiment 3: This embodiment is described in conjunction with Embodiments 1 to 2. The ejector humidifier 10 includes an ejector 101 and a No. 1 humidifier 102. The gas outlet of the hydrogen buffer tank 23 is connected to the high-pressure fluid inlet of the ejector 101 through a pipeline. , the outlet of the ejector 101 is connected to the inlet of the No. 1 humidifier 102 through the pipeline, and the outlet of the No. 1 humidifier 102 is connected to the anode end of the electric stack 1 through the pipeline. In this way, the use of the ejector 101 reduces the traditional circulation pump belt coming parasitic power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com