Rapid pressure-bearing forming device and method for physical similar material test piece

A technology of physically similar and similar materials, applied in the field of rapid pressure-bearing molding devices, can solve the problems of low production efficiency, high error in the pressing process, difficulty in producing high-density similar material test pieces, etc., so as to reduce weight and reduce circumferential deformation. , the effect of reducing the cost and time of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

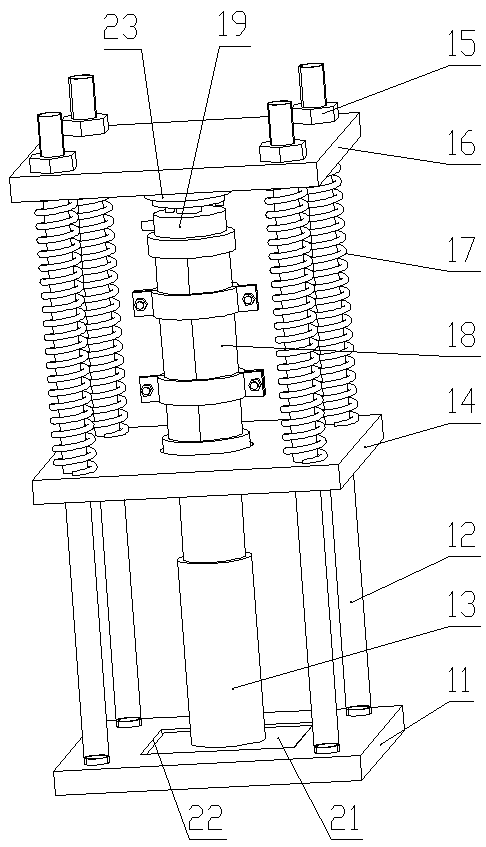

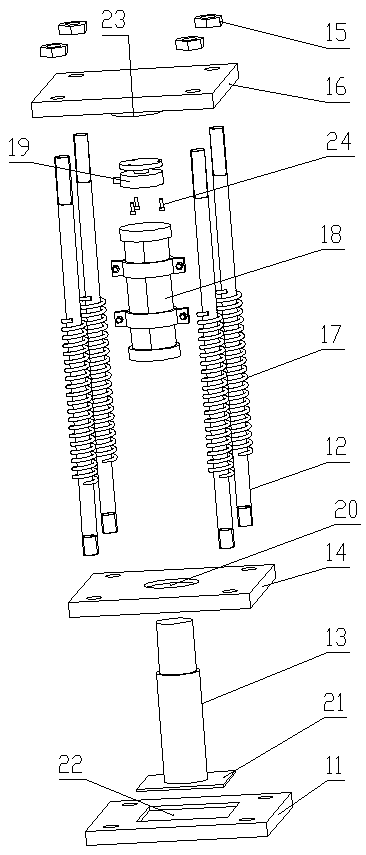

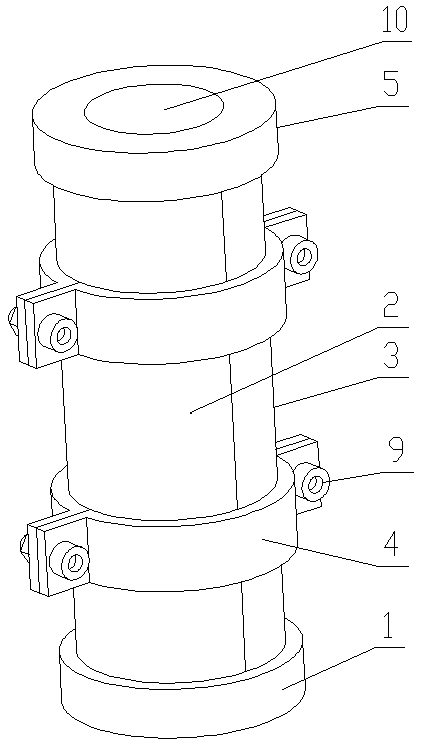

[0048] Such as Figure 1-Figure 4 As shown, the rapid pressure-bearing forming device for physically similar material specimens includes a strain gauge (not shown in the figure) and a horizontally arranged lower plate 11. The upper surface of the lower plate 11 is provided with four guide posts 12 in a rectangular array, and the lower plate 11 is provided with a hydraulic jack 13, the hydraulic jack 13 and the four guide posts 12 are arranged in the vertical direction, the sliding sleeves on the four guide posts 12 are provided with a middle plate 14, and the upper ends of the four guide posts 12 are provided with upper ends through a nut assembly 15. Plate 16, each guide post 12 is sleeved with a compression spring 17 located between the upper plate 16 and the middle plate 14. Under the elastic force of the compression spring 17, the upper end of the hydraulic jack 13 is fixed to the lower surface of the middle plate 14. Press-fitting, a test piece forming mold 18 is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com