A Method for Predicting the Mechanical Life of a High Voltage Circuit Breaker

A high-voltage circuit breaker, mechanical life technology, applied in circuit breaker testing, mechanical component testing, machine/structural component testing, etc., can solve the problem of inability to accurately predict the mechanical life of high-voltage circuit breakers, and achieve the effect of accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

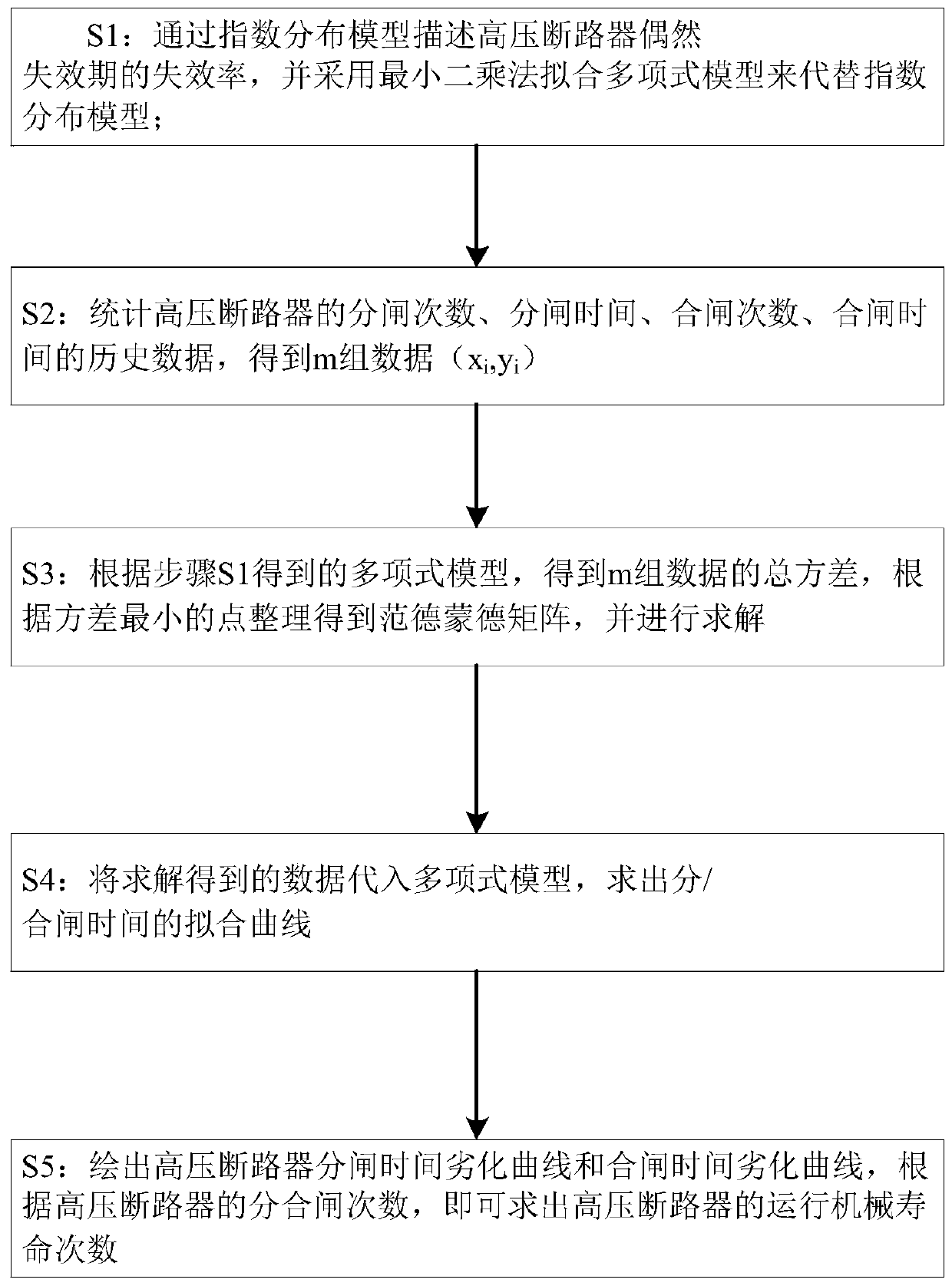

Method used

Image

Examples

Embodiment 1

[0042] A high-voltage circuit breaker (or high-voltage switch) can not only cut off or close the no-load current and load current in the high-voltage circuit, but also act as a relay protection device when the system fails.

[0043] The closing (closing) process of the high-voltage circuit breaker is as follows: the closing release is electrified—the closing release operates—the closing release is completed—the closing spring releases energy—through the cam and the transmission parts ( For example, four connecting rods) - the transmission parts of the circuit breaker (knuckle arm and insulating pull rod, steel pull rod) - drive the contact system to close, and the contact system moves at a certain closing speed - the arc contact is closed The node of gate time.

[0044] The corresponding closing time includes: the charging time of the closing release - the action time of the closing release - the closing time of the contact, that is, the closing speed will affect the length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com