Explosion-proof double-layer high-pressure hydrogen storage tank

A high-pressure hydrogen and storage tank technology, applied in gas/liquid distribution and storage, container discharge methods, container filling methods, etc. Simple structure, obvious economic advantages, and the effect of reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content of the present invention more clearly, further description will be made below in conjunction with specific embodiments.

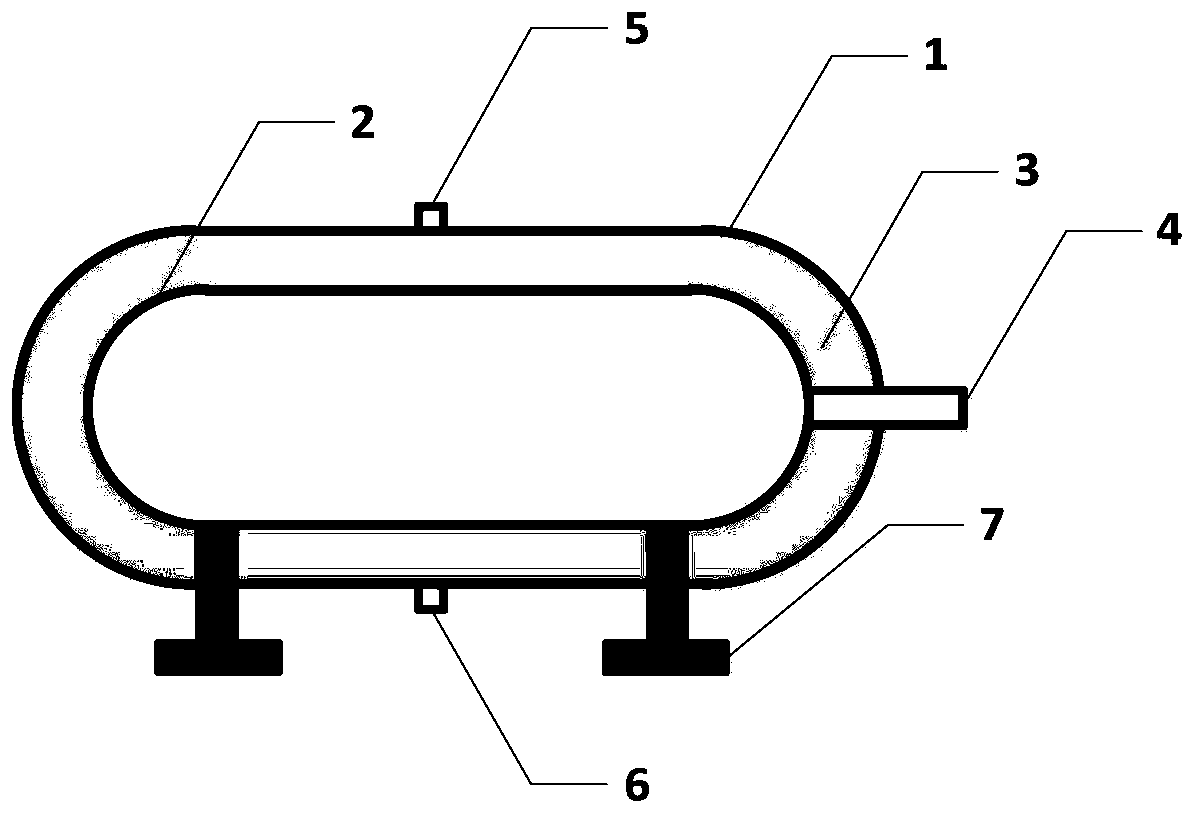

[0030] Figure 1 ~ Figure 3 They are schematic diagrams of horizontal cylindrical storage tank, vertical cylindrical storage tank and spherical storage tank respectively. Wherein, the tank body is a double-layer structure, consisting of an inner tank 2 and an outer tank 1, the inner tank 2 and the outer tank 1 are connected as a whole through the tank seat 7; a sandwich 3 is formed between the inner tank 2 and the outer tank 1, and the inner tank 3 Filled with antiknock agent, said antiknock agent can be liquid water, compressed nitrogen, liquid nitrogen, compressed carbon dioxide, liquid carbon dioxide, or other antiknock agents, and the outer tank 1 is provided with an antiknock agent inlet 5 and an antiknock agent outlet 6. It is used to fill or release the anti-knock agent filling into the interlayer 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com