Large dip angle soft thick coal seam top coal roadway surrounding rock control method

A control method and a technology with a large inclination angle, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficulty in exerting the bearing capacity of deep stable rock mass, insufficient control of soft rock roadways, and poor stability of support structures, etc., to achieve improved support. The effect of protecting quality, improving stability and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

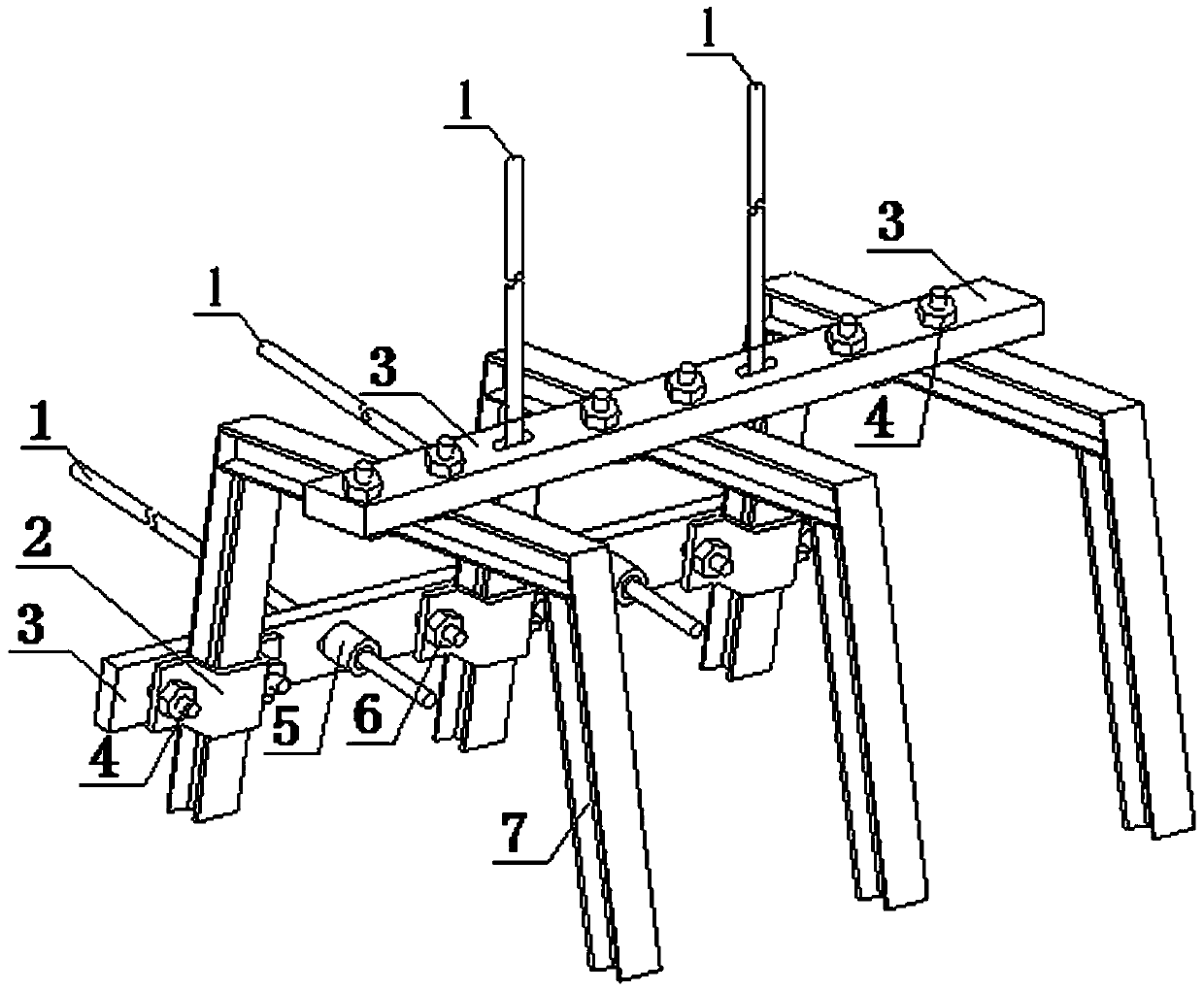

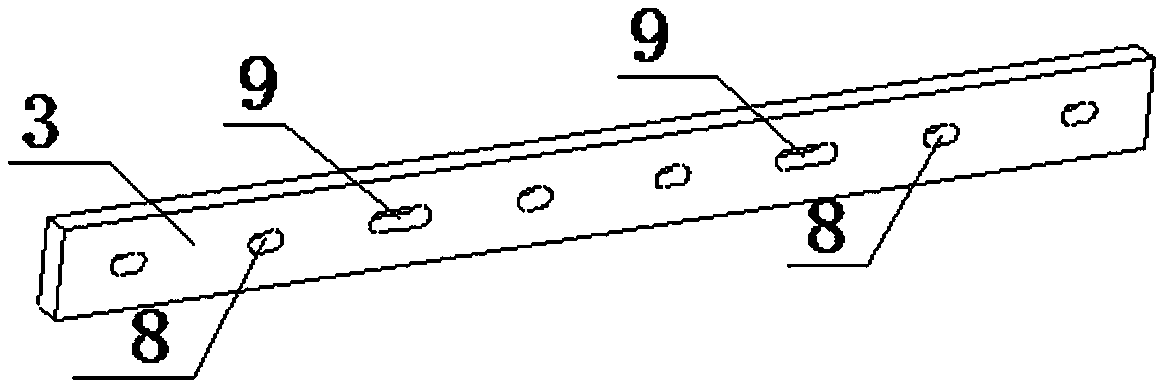

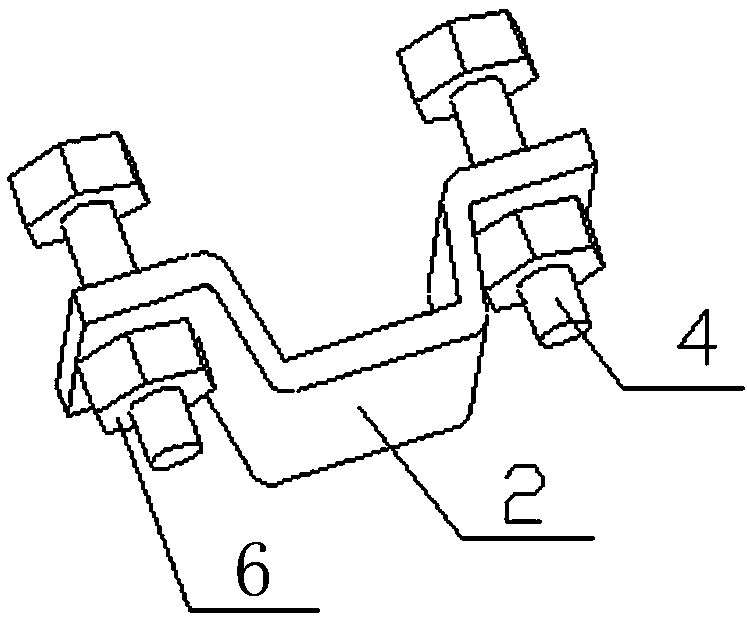

[0039] A method for controlling the surrounding rock of a roadway supporting top coal in a soft and thick coal seam with a large dip angle. The surrounding rock of the roadway includes I-shaped steel, and also includes multiple sets of active and passive combined roadway protection devices matched with the I-shaped steel. The active and passive combined roadway protection device described in a single group The roadway protection device is composed of an I-shaped steel bracket 7, a guard plate 3, an I-shaped steel buckle 2, an anchor cable 1, a lock 5 and a screw connector 6. The I-shaped steel bracket 7, the guard plate 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com