Rotatable type lifting stage

A rotary, stage technology, used in theaters and other directions, can solve the problems of a single structure, can not achieve performance effects, can not well meet the requirements of various forms of performance, and achieve the effect of improving service life and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

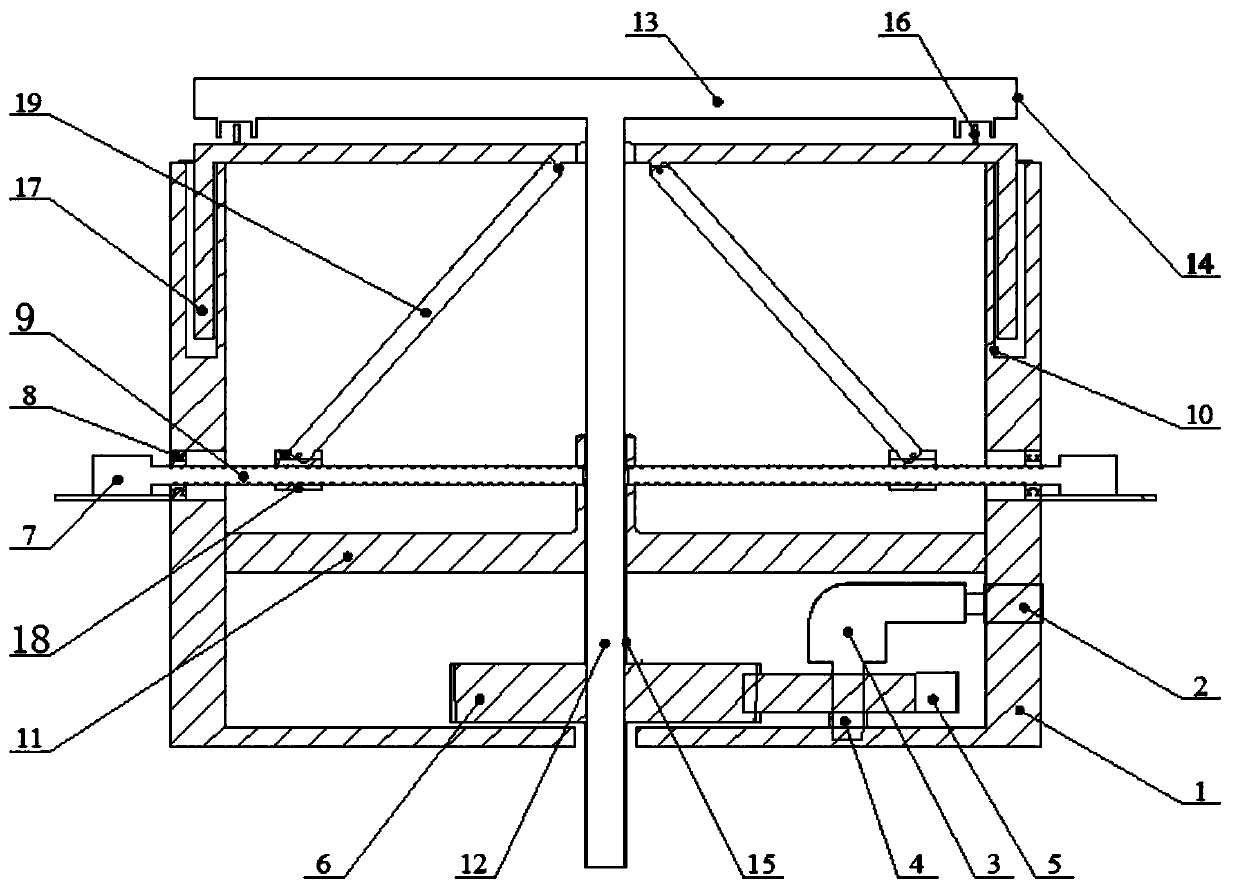

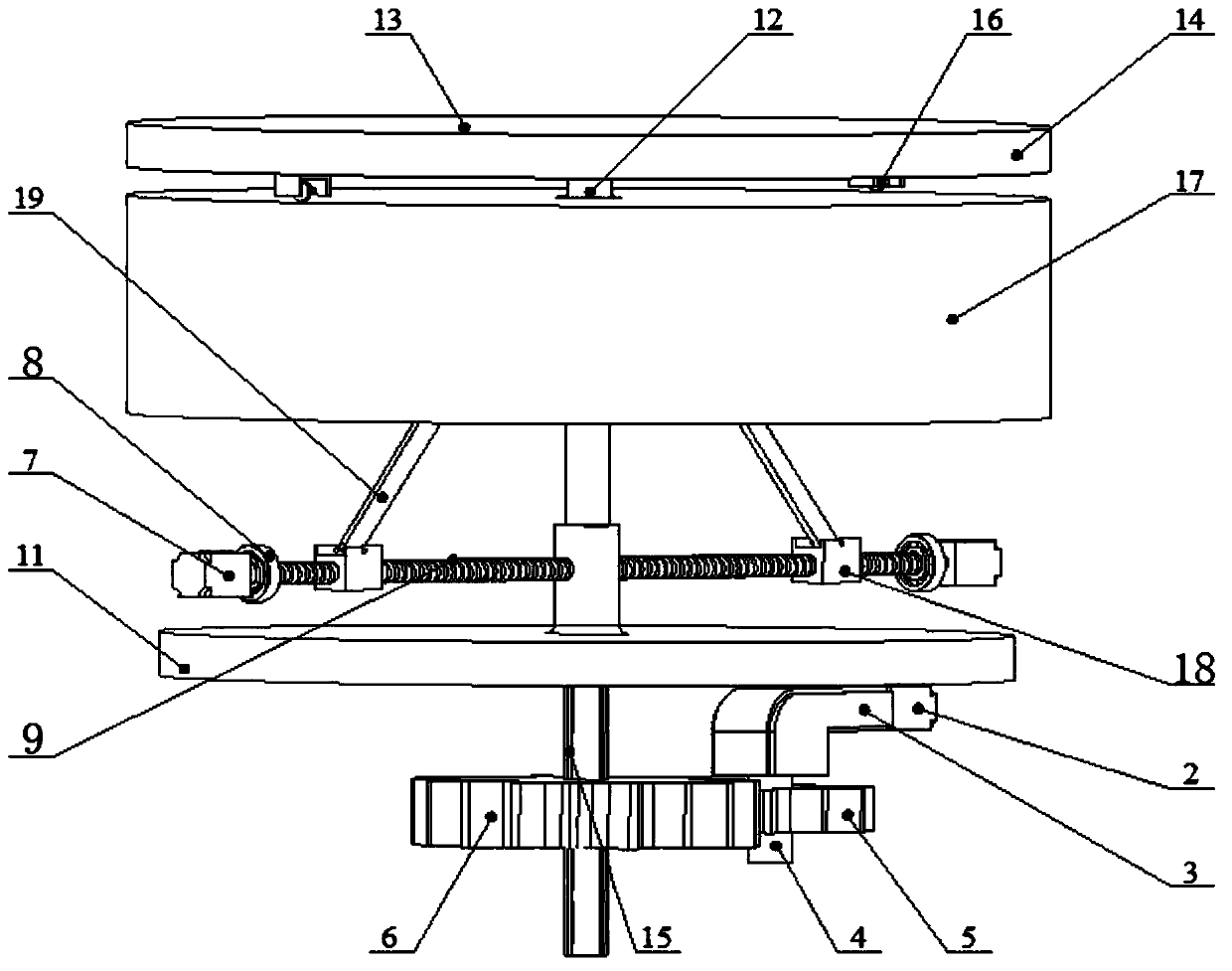

[0025] see figure 1 and figure 2 As shown, the rotatable lifting stage of the invention includes a base 1, a stage plate 13, a rotating device and a lifting device.

[0026] Abutment 1 is a cylinder with an open top, hollow inside, and a ring on the top surface. A circle of grooves 10 is provided on the ring, and the grooves 10 extend along the axis of Abutment 1. Two opposite first through holes, a bushing 11 is provided in the middle of the cavity of the abutment 1, and the inner ring of the bushing 11 extends upwards to form a boss, and two opposite second through holes are arranged on both sides of the peripheral surface of the boss. A first through-hole and two second through-hole axes are collinear.

[0027] The stage plate 13 is located above the base 1, and the center of the bottom circle is connected with the rotating shaft 12, the axis of the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com