Water-saving washing machine drainage device and washing machine

A technology for a water-saving washing machine and a drainage device, which is applied in the field of washing machines, can solve the problems of reducing the concentration of detergent, large waste of water resources, waste, etc., and achieves the effects of low manufacturing cost, simple structure and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

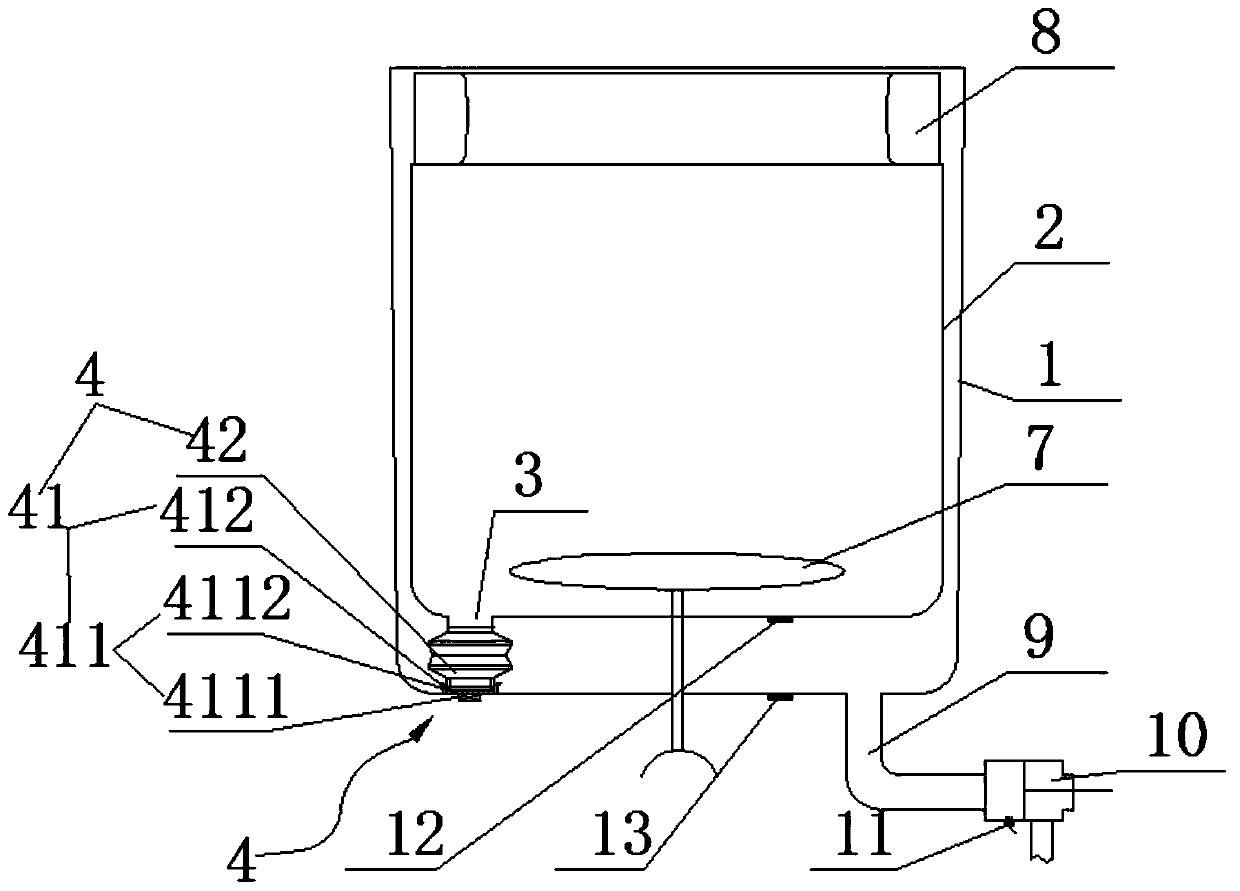

Embodiment 1

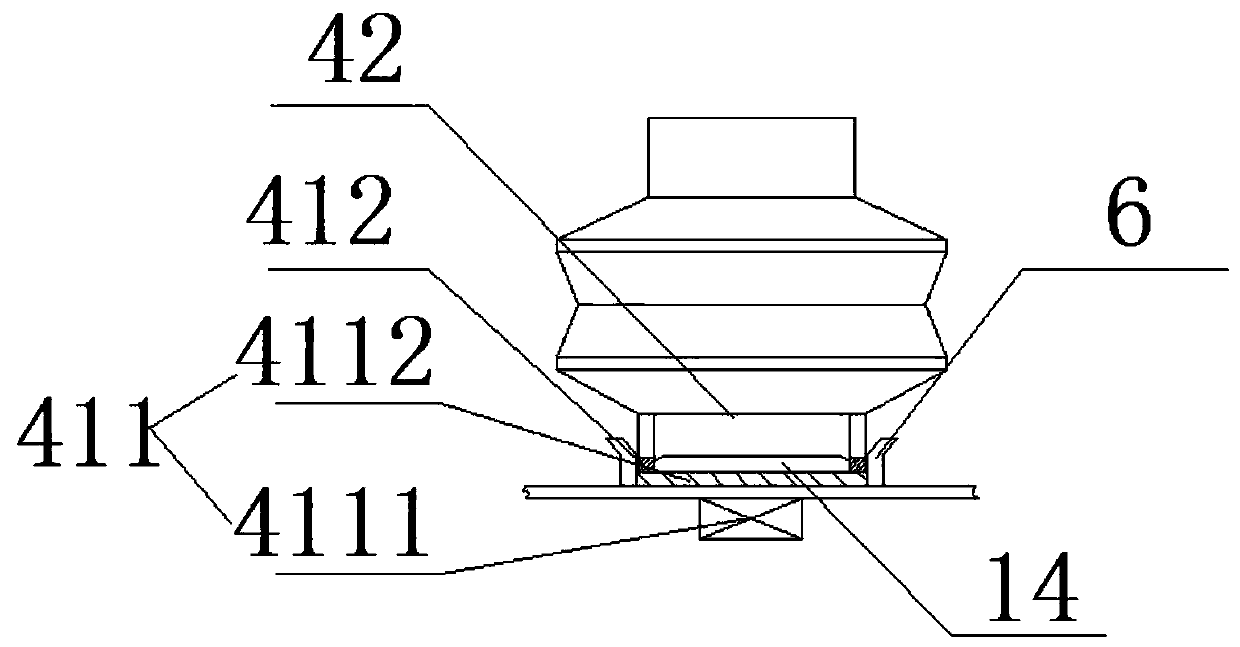

[0043] In this embodiment, the bellows 42 is connected to the drain hole 3; the drain driving device 41 includes an electromagnetic mechanism 411 and a magnetic ring 412. Wherein, the electromagnetic mechanism 411 is located on the bottom end of the outer cylinder 1 and corresponding to the bellows 42; the magnetic ring 412 is located on the lower end of the bellows 42; the electromagnetic mechanism 411 is connected to the magnetic The ring 412 tightly sucks and drives the bellows 42 to extend to seal and close the drain hole 3. The corrugated pipe 42 and the drain hole 3 are connected together by clamps, wire ties, glue, hot melt welding, etc., which is simple to assemble and easy to install. The electromagnetic mechanism 411 generates electromagnetic force, which causes the magnetic ring 412 to move downward to attract the electromagnetic mechanism 411. At this time, the bellows 42 is drawn by the magnetic ring 412, extends downward, and cooperates with the electromagnetic me...

Embodiment 2

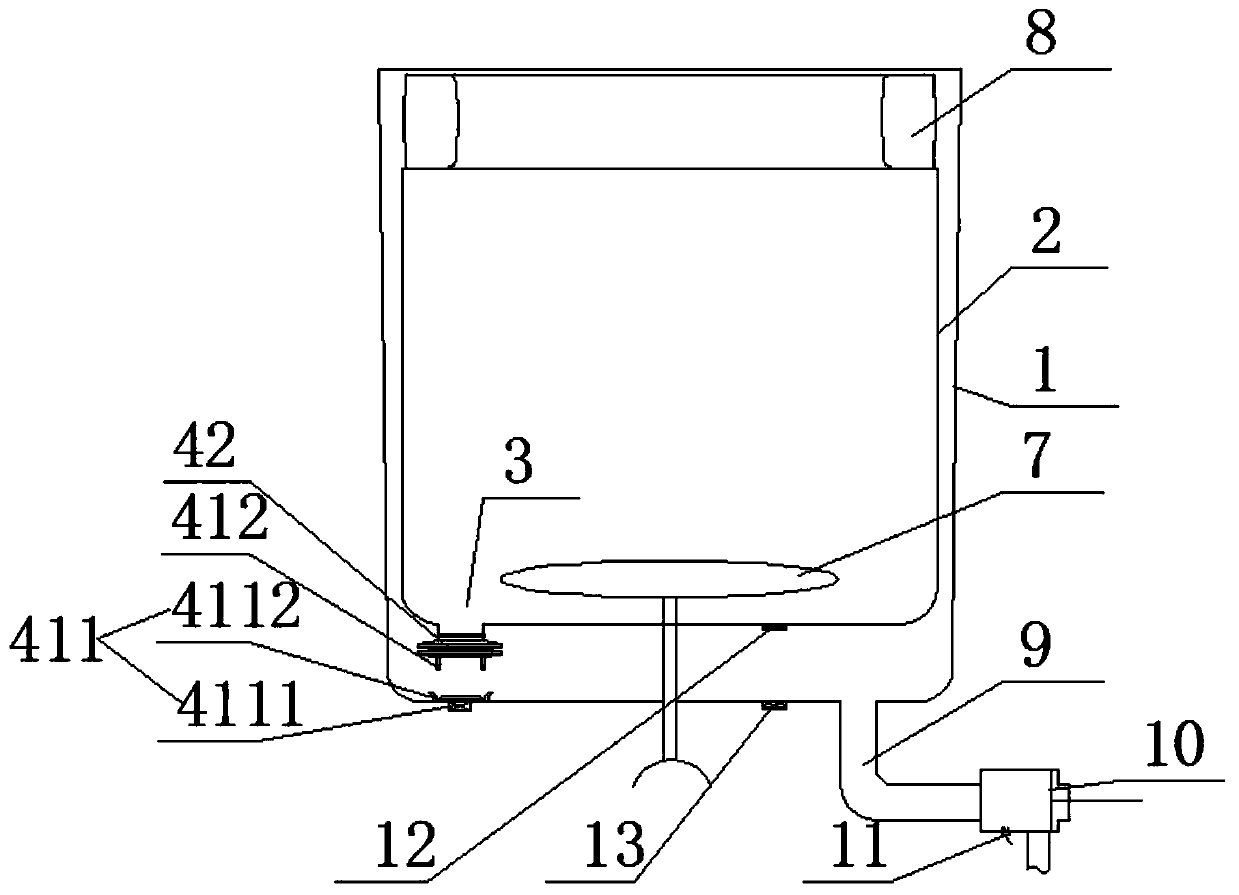

[0053] In the second embodiment, the drainage device of the water-saving washing machine in this embodiment is basically the same as that in the first embodiment, except that: Image 6 The bellows 42 is located on the bottom end of the outer cylinder 1 and is provided corresponding to the drain hole 3; the drain driving device 41 includes an electromagnetic mechanism 411 and a magnetic ring 412. Wherein, the electromagnetic mechanism 411 is provided on the upper end of the bellows 42; the magnetic ring 412 is connected to the drain hole 3; the electromagnetic mechanism 411 is closely attracted to the magnetic ring 412 after being energized to drive the bellows 42 extends to seal and close the drain hole 3. The positional relationship among the bellows 42, the electromagnetic mechanism 411 and the magnetic ring 412 is changed, but the function of no water between the outer cylinder 1 and the inner cylinder 2 can also be realized. The electromagnetic mechanism 411 generates elect...

Embodiment 3

[0055] In the third embodiment, the drainage device of the water-saving washing machine in this embodiment is basically the same as that in the first embodiment, except that: Figure 4 with Figure 5 A telescopic mechanism 5 connected to the electromagnetic mechanism 411 and driving the electromagnetic mechanism 411 to telescopically move relative to the drain hole 3 is provided on the bottom of the outer cylinder 1. In order to better adsorb the magnetic ring 412 at the lower part of the corrugated tube 42 and meet the requirements of the distance between the inner cylinder 2 and the outer cylinder 1, a telescopic mechanism 5 is added at the bottom of the outer cylinder 1. The telescopic mechanism 5 includes a motor, The transmission mechanism and the telescopic telescopic connecting rod are connected with the electromagnetic mechanism 411. In the washing state, the motor drives the telescopic connecting rod to move upward, and the electromagnetic mechanism 411 is tightly sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com