Preparation method of gasification formed coke used for Lurgi furnace

A technology of gasification type and Lurgi furnace, which is applied in the field of preparation of gasification coke for Lurgi furnace, which can solve problems such as rising production costs of Lurgi furnace users, squeezed corporate profits, and increased difficulty in tail water treatment. , to achieve the effect of reducing the difficulty of tail water treatment, increasing the effective load, and improving the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of gasification coke for Lurgi furnace, specifically including the following steps:

[0020] a) The raw material is selected from the under-sieve coal produced by Lu'an Yuwu Coal Industry: pulverized coal is sieved, and the under-sieve coal with a 5mm sieve is crushed to a particle size of less than 3mm.

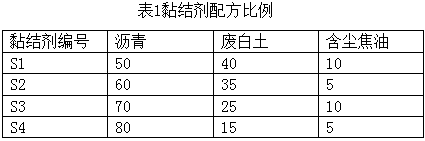

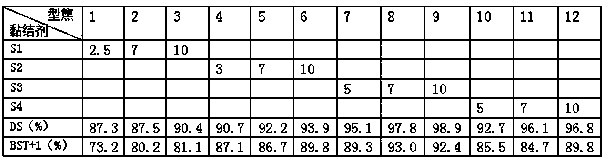

[0021] b) Take 5% of the weight of coal powder and mix it with the alkali metal carbonate coal gasification catalyst, and then add 10% of the binder step by step according to the proportion: first add asphalt and waste clay, and mix evenly with a double-shaft mixer; Then move the coal and binder mixture to the next double-shaft mixer, spray the ethanol aqueous solution to fully moisten and stir evenly; then move the material to the next double-shaft mixer, add dust-containing tar and stir evenly; the binder contains 50% asphalt , 40% waste clay and 10% dust tar.

[0022] c) Graphite is pressed into a block of 50x50x50cm, the coal obtained by the above s...

Embodiment 2

[0026] A preparation method of gasification coke for Lurgi furnace, specifically including the following steps:

[0027] a) The raw material is selected from the under-sieve coal produced by Lu'an Yuwu Coal Industry: pulverized coal is sieved, and the under-sieve coal with a 5mm sieve is crushed to a particle size of less than 3mm.

[0028] b) Mix the vanadium-based coal gasification catalyst with 6% of the pulverized coal weight with the coal, and then add 12% of the binder step by step according to the proportion: first add the asphalt and waste clay, use a double-shaft mixer to mix evenly; then mix the coal The mixture of material and binder is moved to the next double-shaft mixer, sprayed with ethanol solution to fully wet and stir evenly; then the material is moved to the next double-shaft mixer, dust-containing tar is added and mixed evenly; the binder contains 60% asphalt and 35% Waste white clay and 5% dust tar.

[0029] c) Graphite is pressed into a block of 50x50x50cm, the...

Embodiment 3

[0032] A preparation method of gasification coke for Lurgi furnace, specifically including the following steps:

[0033] a) The raw material is selected from the under-sieve coal produced by Lu'an Yuwu Coal Industry: pulverized coal is sieved, and the under-sieve coal with a 5mm sieve is crushed to a particle size of less than 3mm.

[0034] b) Take 4% of the vanadium-based coal gasification catalyst by weight of pulverized coal and mix it with the pulverized coal, and then add 3% of the binder step by step according to the proportions: first add asphalt and waste clay, mix well with a double-shaft mixer; then mix the coal The mixture of material and binder is moved to the next twin-shaft mixer, sprayed with ethanol aqueous solution to fully wet and stir evenly; then the material is moved to the next twin-shaft mixer, dust-containing tar is added and mixed evenly; the binder contains 70% asphalt and 25% Waste clay and 10% dust tar.

[0035] c) Graphite is pressed into a block of 50x5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com