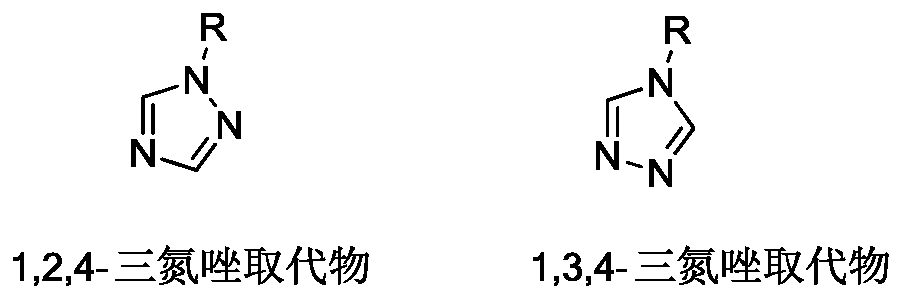

Method for reducing 1,3,4-triazole substituent in 1,2,4-triazole alkylation reaction process

An alkylation reaction and triazolidine technology, which is applied in the field of reducing 1,3,4-triazolidine substitutes in the process of 1,2,4-triazolidine alkylation, can solve the problem of poor yield. It can shorten the reaction time, simplify the operation and reduce the reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The synthesis of tebuconazole: 1,2,4-triazole (17.44g, 252.5mmol), sodium hydroxide (10.4g, 259.9mmol), triethylbenzyl ammonium chloride 2.8g, N, N- 10g of dimethylformamide was put into the reaction flask, and after preheating to 80°C, 2-(4-chlorophenethyl)-2-tert-butyloxirane (59.1g, 247.5mmol) was added dropwise. When the temperature is controlled at ≤95°C, after the dropwise addition is completed, it is kept at 98-102°C for 2-3 hours. After the heat preservation is completed, water is added to separate the layers, and the organic layer is washed with water until the pH<8. After the organic layer is desolvated under negative pressure, the obtained Tebuconazole finished product 74.5g, content 97.8%, yield 95.6%.

Embodiment 2

[0028] Synthesis of epoxiconazole: 2-bromomethyl-2-(4-fluorophenyl)-3-(2-chlorophenyl)-oxirane (58.1g, 170.02mmol), 1,2,4 -Triazole (12.9g, 187.0mmol), sodium hydride (4.6g, 190.42mmol) and tetramethylammonium chloride 2.3g were placed in a reaction flask, heated to 70°C and stirred for 1-2 hours, then cooled after the reaction was complete Bring to room temperature, add water to separate layers, wash and dry the organic layer with water, saturated sodium chloride solution, and water successively, and desolvate under reduced pressure to obtain 53.8 g of epoxiconazole, with a content of 97.2% and a yield of 93.3%.

Embodiment 3

[0032] Synthesis of epoxiconazole: 2-methylsulfonate-2-(4-fluorophenyl)-3-(2-chlorophenyl)-oxirane (69.31g, 194.3mmol), 1, 2,4-Triazole (14.1g, 204.0mmol), sodium hydride (5.4g, 223.4mmol) and 1.2g of tetrabutylammonium bromide were dissolved in 5g of DMF, heated to 60°C and stirred for 1-2 hours, and the reaction was complete After cooling to room temperature, adding water to separate layers, the organic layer was washed with water, saturated sodium chloride solution, and water successively and dried. After precipitation under reduced pressure, 60.8 g of epoxiconazole was obtained, with a content of 97.3% and a yield of 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com