Microaerobic biological treatment system and method for degrading cyclic compounds in coal pyrolysis wastewater

A treatment system and micro-aerobic biological technology, applied in the field of micro-aerobic biological treatment system, can solve the problems of increased sludge treatment pressure, difficult separation, and unrecyclable materials, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

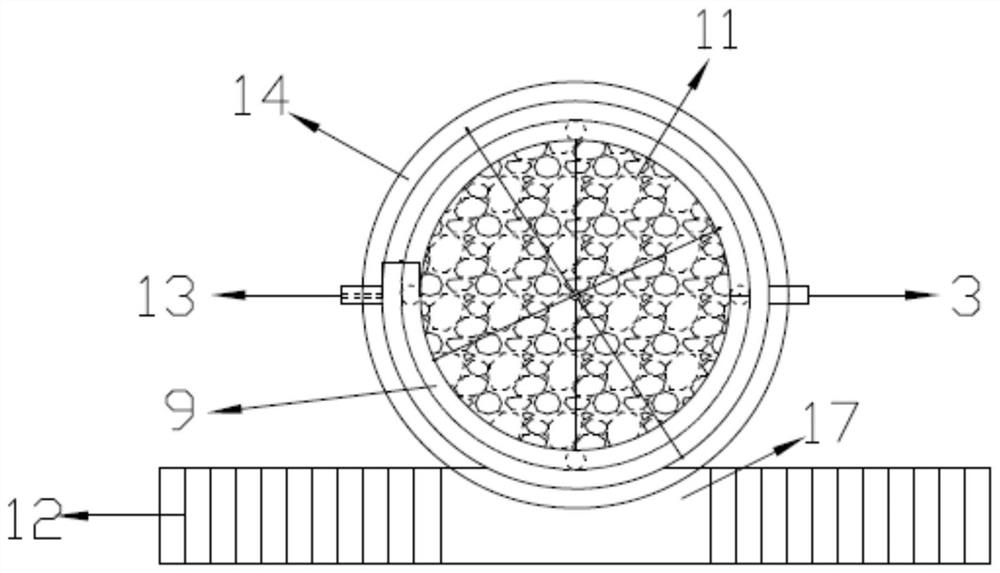

[0029]Specific Embodiment 1: In this embodiment, a micro-aerobic biological treatment system is a semi-underground cylindrical structure, including a micro-aerobic active coke carrier mobile biological bed system, a semi-coke filter layer system, and a material recovery system. The coke carrier mobile biological bed system is located below the ground 19. The micro-oxygen activated coke carrier mobile biological bed system includes a blower 1, a microporous air disc aeration device 2, a water inlet pipe 3, at least one submersible mixer 4, activated sludge, and a magnetic reformer. Active coke 5, multi-parameter water quality monitor 6 and pool a 20, the semi-coke filter layer system includes filter material support layer 7, semi-coke 11, water outlet pipe 13, liquid level sensor 15, pressure measuring tube 16, annular water outlet Weir 18 and pool b 21, the material recovery system includes electromagnetic lifting pulley device 9 and electromagnetic recovery device 10;

[0030...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the material recovery system also includes a staircase 12, a movable cover 14 and a filter material replacement platform 17, and the movable cover 14 is arranged on the microaerobic biological treatment At the top of the system, a staircase 12 is arranged on one side of the microaerobic biological treatment system, and the top of the staircase 12 is a filter replacement platform 17.

[0032] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the filter material support layer 7 is composed of an upper and lower structure, and the upper and lower structures are vertically provided with support layer holes 8, and the upper and lower structures The holes 8 in the supporting layer are dislocated, and the inner wall of the top of the annular outlet weir 18 is evenly distributed with a sawtooth structure along the horizontal direction.

[0034] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com