Ceiling fixing fastener

A technology for fixing buckles and ceilings, which is applied in the direction of friction clamping detachable fasteners, vehicle parts, connecting components, etc., which can solve problems such as troublesome and long processing cycles, and achieve reduced installation gaps, strong connection stability, and easy disassembly. The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

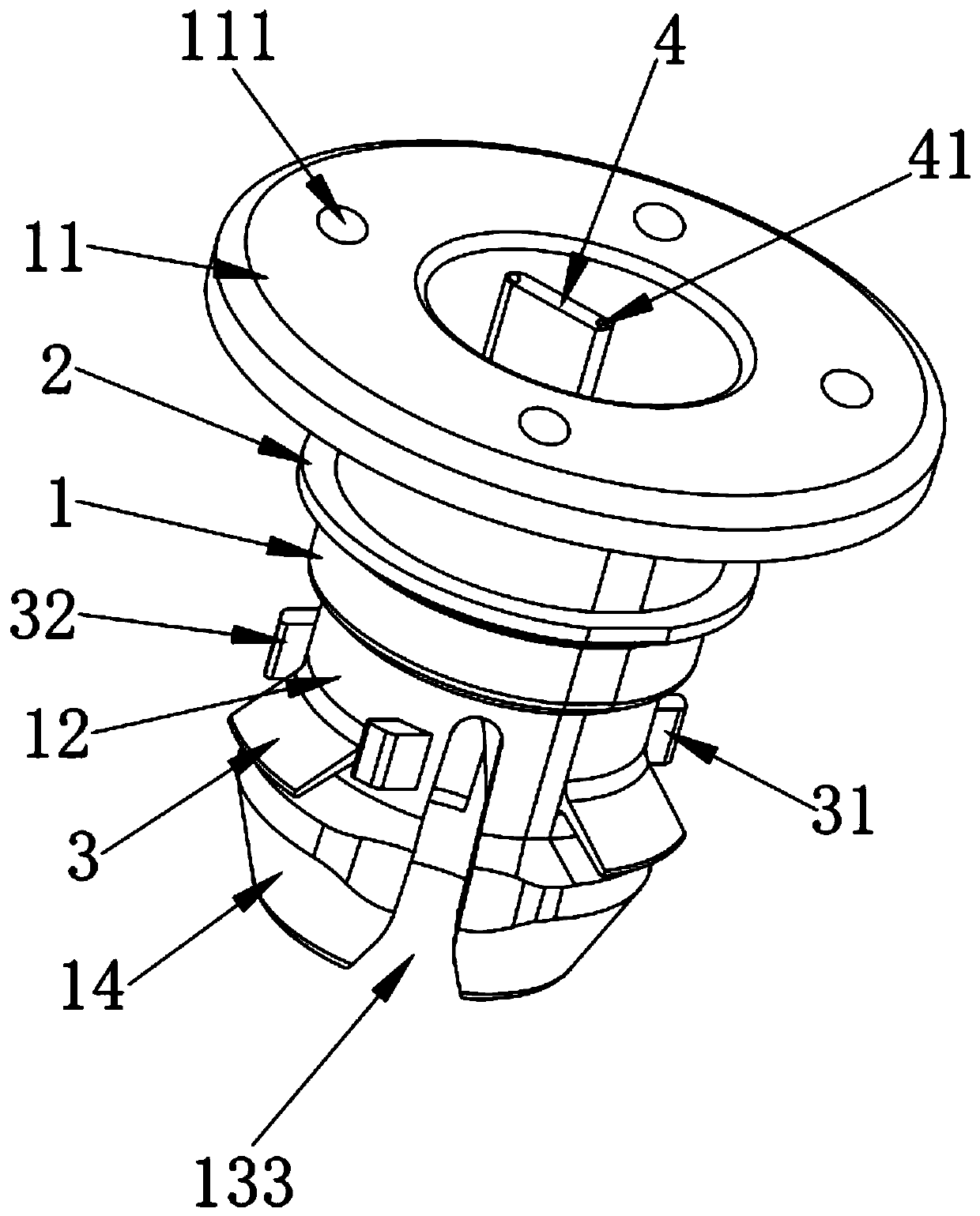

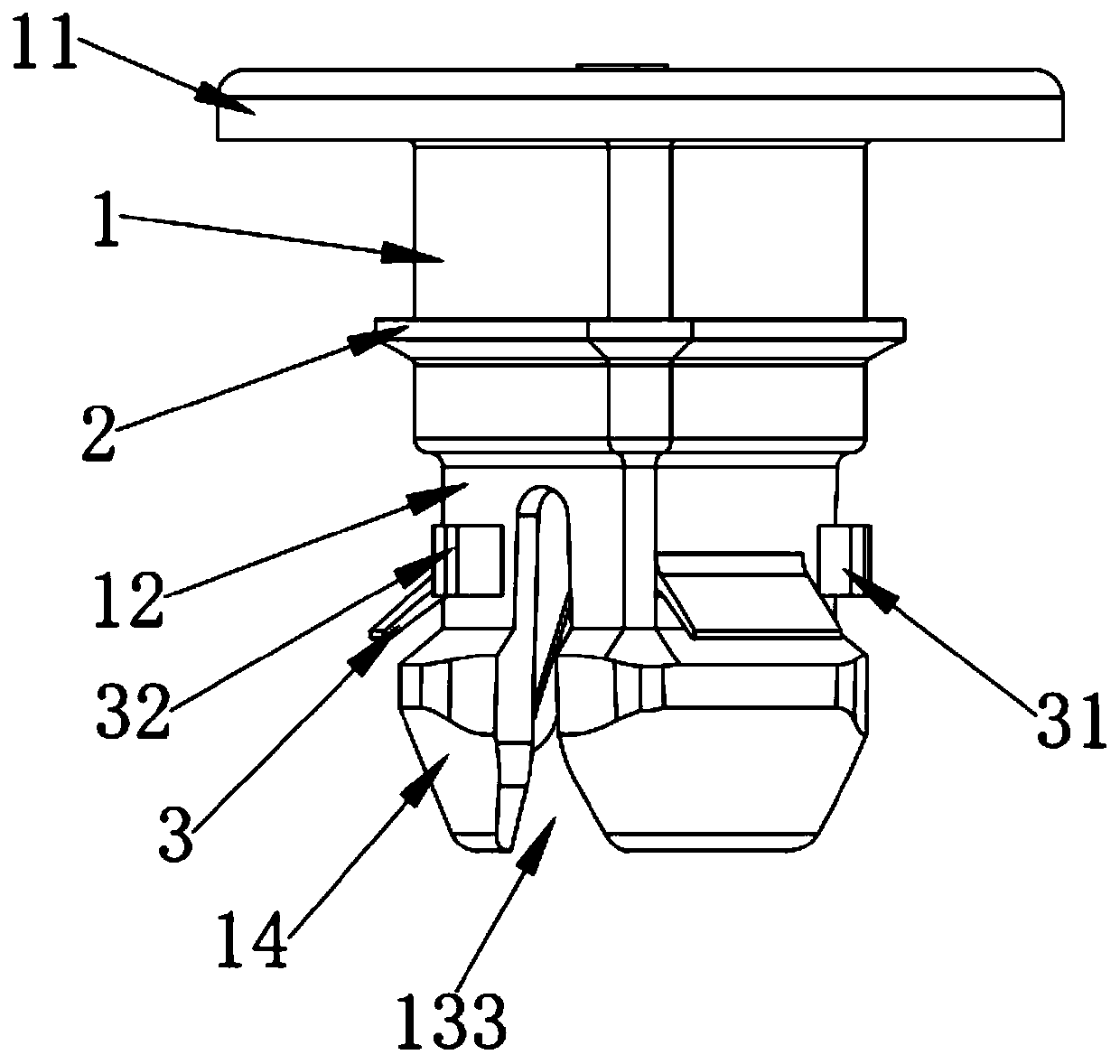

[0022] Depend on figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is composed of a cylindrical fastener body 1, etc., a button cover 11 is provided on one side of the fastener body 1, and an annular groove 12 is arranged on the other side, and the groove wall of the annular groove 12 is Both are inclined-plane structures; a limiting ring block 2 is provided between the ring groove 12 and the buckle cover 11, and the lower end surface of the limiting ring block 2 is provided with a bevel for making way.

[0023] A first opening groove 131, a second opening groove 132 and a third opening groove 133 are arranged on the fastener body 1 along the circumferential direction. On the axial direction of the three opening grooves, one end of the corresponding fastener body 1 is provided There is an open end, and the position of the open en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com