Drilling equipment for machining circumferential normal hole of pipe fitting

A drilling equipment and hole processing technology, which is applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve the problems of inability to achieve processing effects, low hole processing efficiency, large deflection of pipe fittings, etc., to avoid pipe fittings The effect of extreme symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

[0046] Figure 1 to Figure 16 For a preferred embodiment of the present invention:

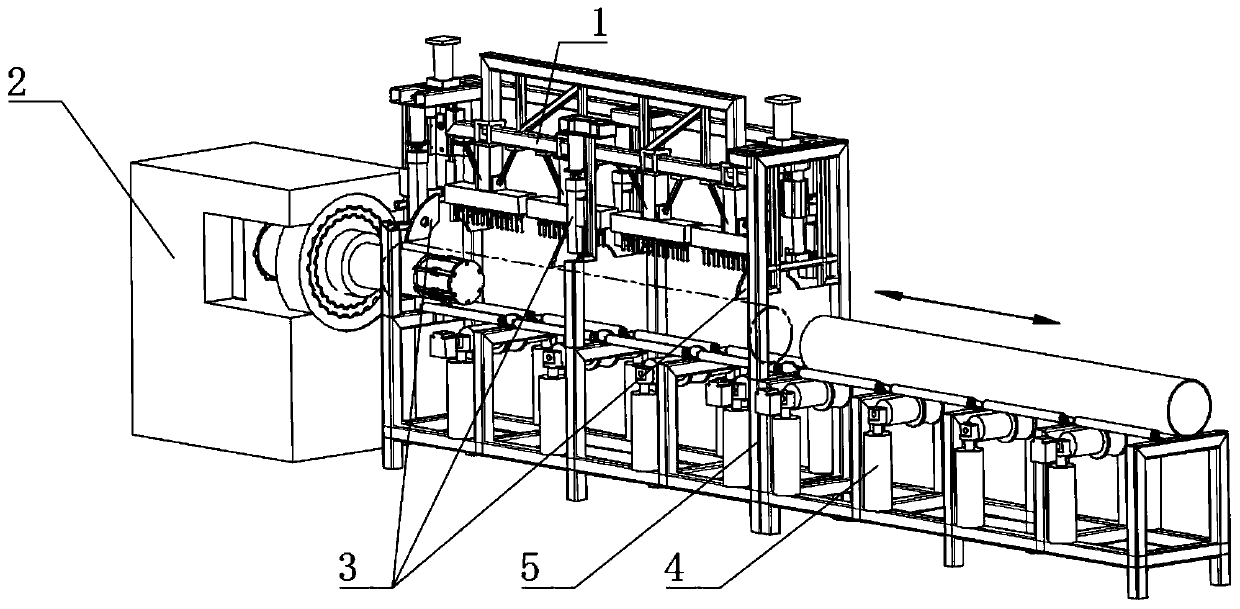

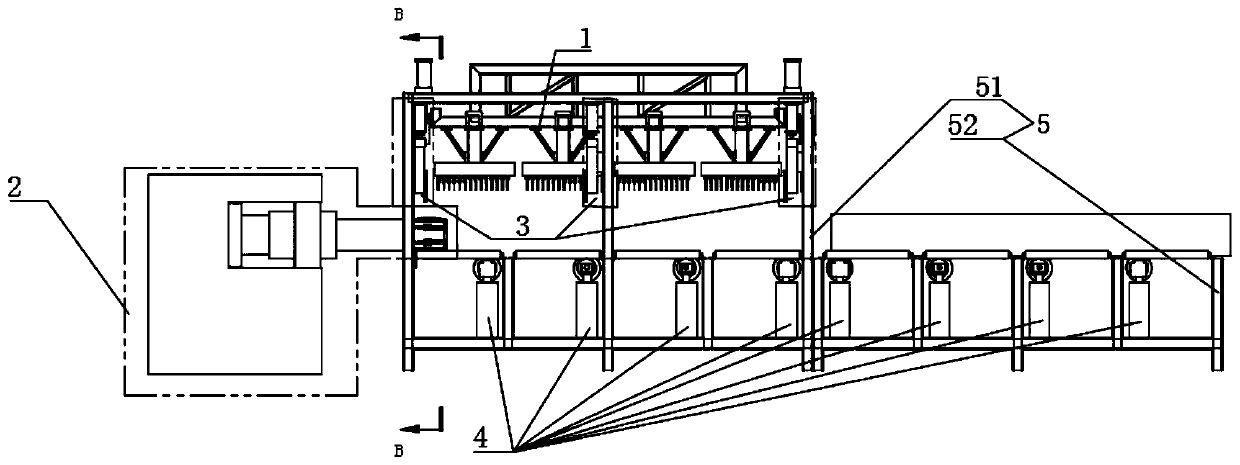

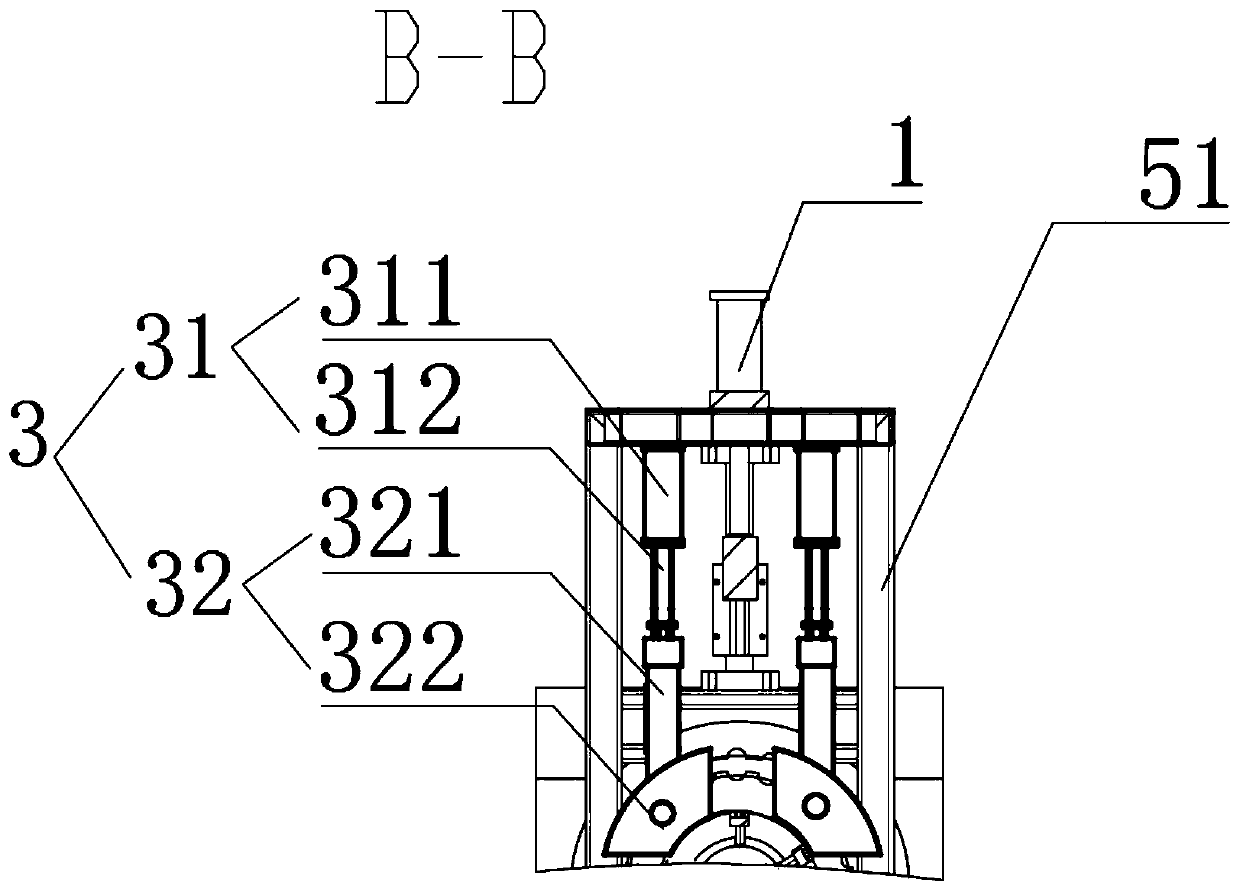

[0047] This embodiment can be used to process the drainage pipe used in the blind ditch system, assuming that the pipe fitting to be processed has a specification length×outer diameter×wall thickness=2000mm×Φ315mm×10mm. Such as figure 1 and figure 2 As shown, the device of the present application includes five major parts: a drilling module 1 , an indexing module 2 , a clamping module 3 , a feeding module 4 and a base frame 5 .

[0048] The pedestal 5 includes figure 2 The upper base frame 51 and the lower base frame 52 are shown, and the lower base frame 52 is used for placing pipe fittings and bearing loads during p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com