Sound field enhanced nanofluid phase change heat transfer micro-channel heat exchanger

A micro-channel heat exchanger and nano-fluid technology, applied in cooling/ventilation/heating transformation, modification using liquid cooling, etc., to achieve the effect of enhancing the heat transfer effect, increasing the speed of bubble movement, and promoting the increase of the number of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

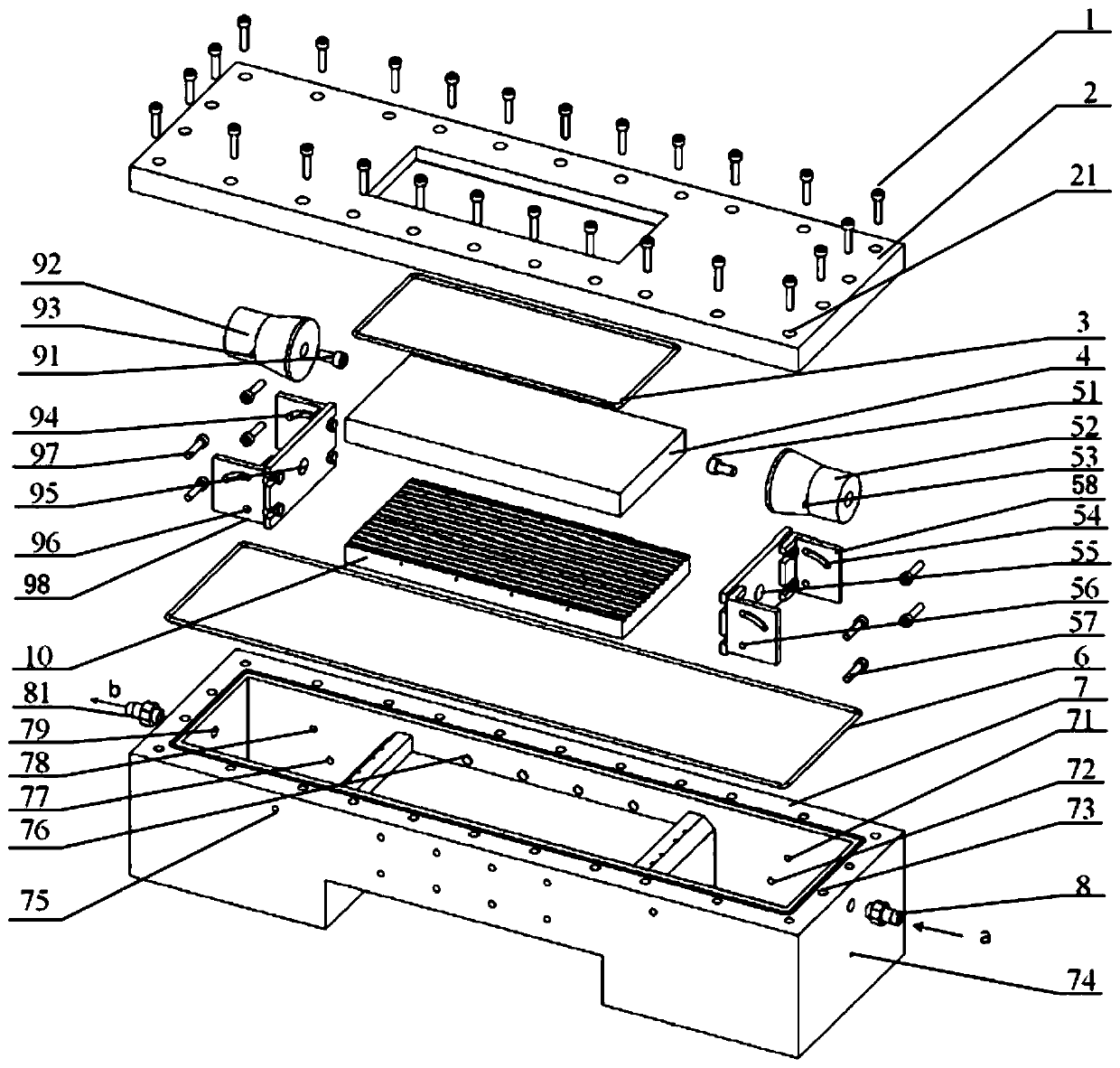

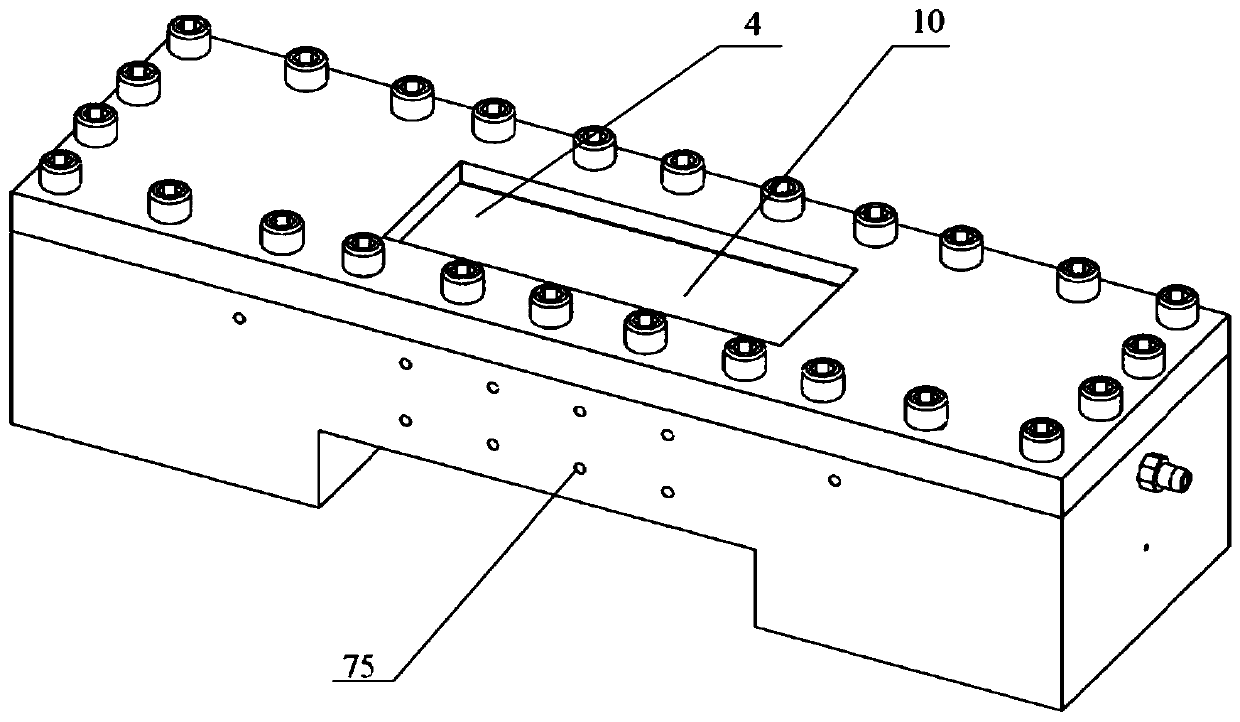

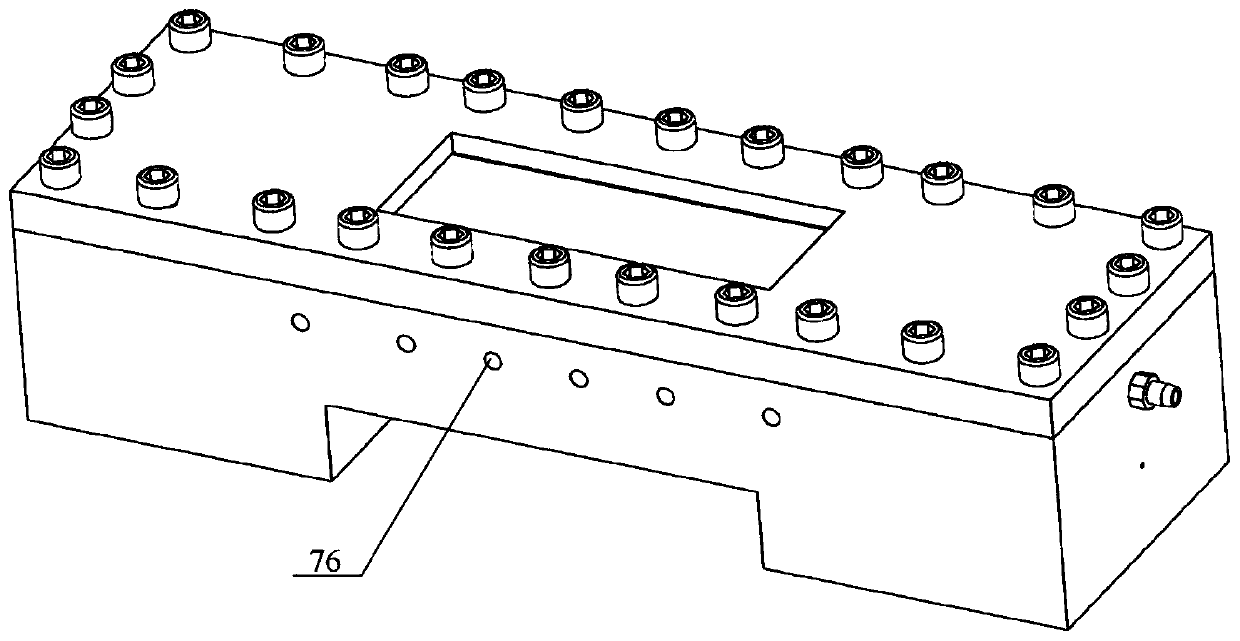

[0035] Such as Figure 1 to Figure 3 As shown, a sound field enhanced nanofluid phase change heat transfer microchannel heat exchanger includes a heat exchanger substrate 7 with a rectangular groove inside, a microchannel substrate 10 arranged in the rectangular groove of the heat exchanger substrate 7, The cover plate 2 is provided with cover plate fixing bolt holes 21, and the top surface of the heat exchanger base 7 is provided with several cover plate fixing screw holes 73, and the cover plate 2 is sealed and covered on the heat exchanger by several bolts 1. At the opening of the rectangular groove of the base 7, the two ends of the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com