Multi-factor width parameter nanofluid heat transfer characteristic experimental system and experimental method

A technology of nanofluid and experimental system, applied in multi-factor wide parameter nanofluid heat transfer characteristics experimental system and experimental field, can solve the problem of nanofluid boiling heat transfer and critical heat flux without considering the influence of pressure and restricting the related mechanism of nanofluid research progress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

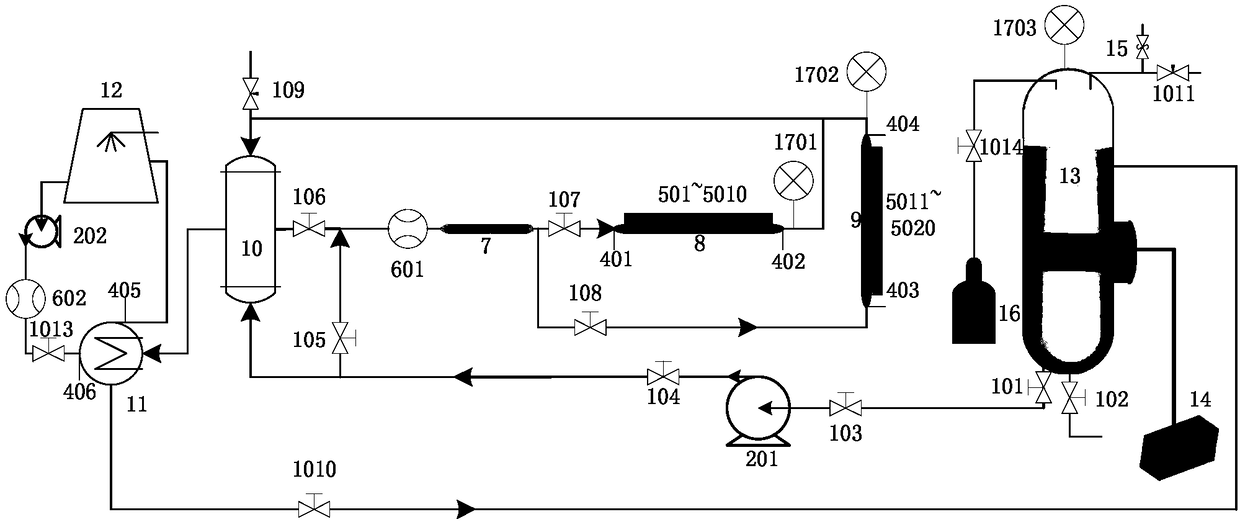

[0037] A multi-factor wide-parameter nanofluid heat transfer characteristic experimental system, including an experimental loop, a cooling loop, and a pressure control loop;

[0038] The experimental circuit consists of a gas-liquid header 13, a pump 201, a regenerator 10, a preheating section 7, a horizontal experimental section 8 and a vertical experimental section 9, a cooling jacket, an ultrasonic oscillator 14, a data acquisition system and an electric heating system The upper end of the gas-liquid header 13 is connected with the nitrogen cylinder 16 through a pipeline, and the high-pressure nitrogen gas is supplemented to the gas-liquid header 13 through the nitrogen cylinder 16, so that the pressure control of the experimental circuit can be realized. The lower end of the gas-liquid header 13 is a heat-exchange working medium. In order to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com