Positive plate and lithium ion battery

A technology of positive electrode sheet and positive electrode film, applied in the field of positive electrode sheet and lithium ion battery, can solve the problems of increasing the manufacturing cost of lithium ion battery, reducing the energy density of lithium ion battery, etc., so as to improve high temperature cycle performance and safety performance, and improve oxidability Strong and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

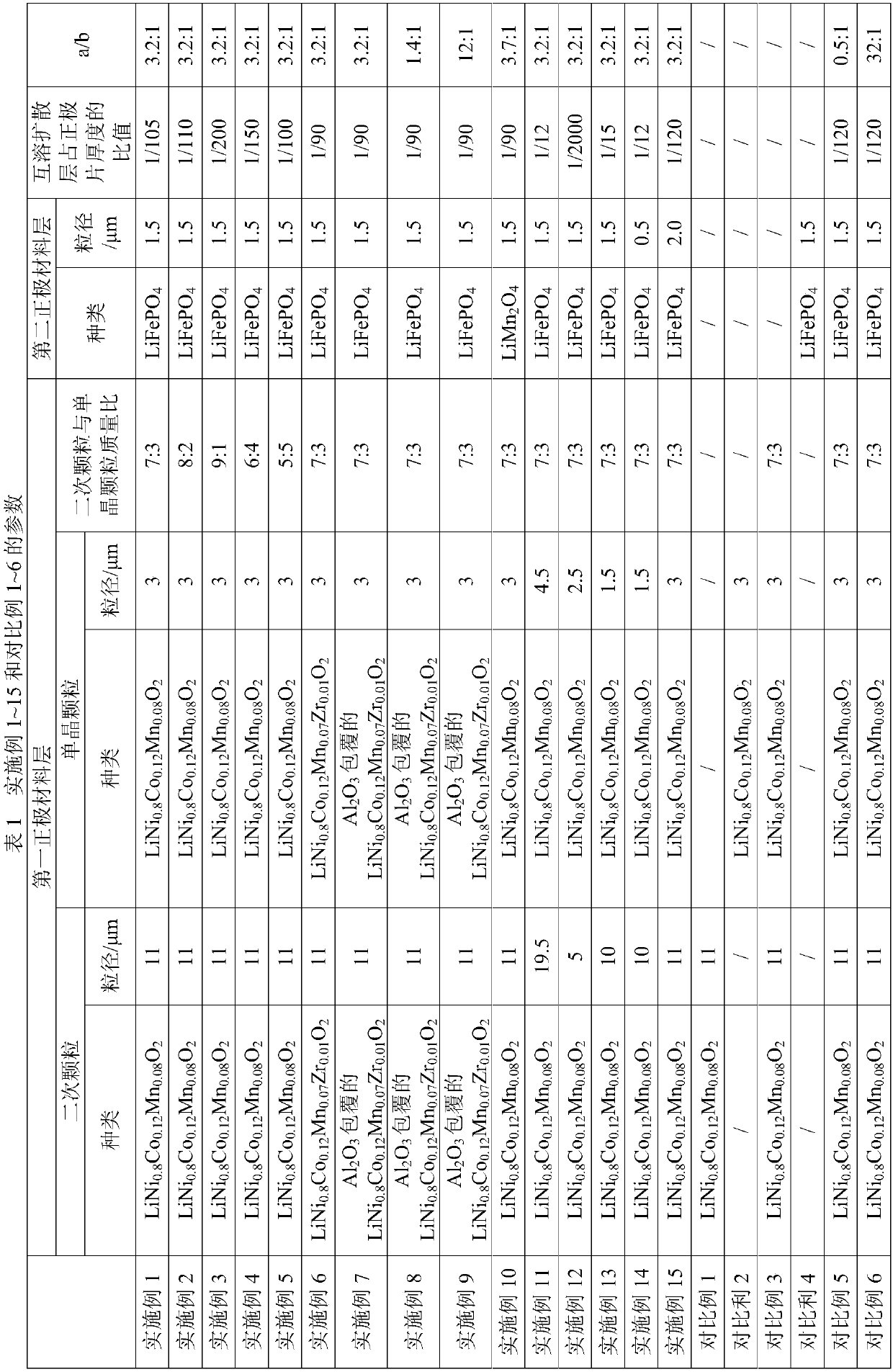

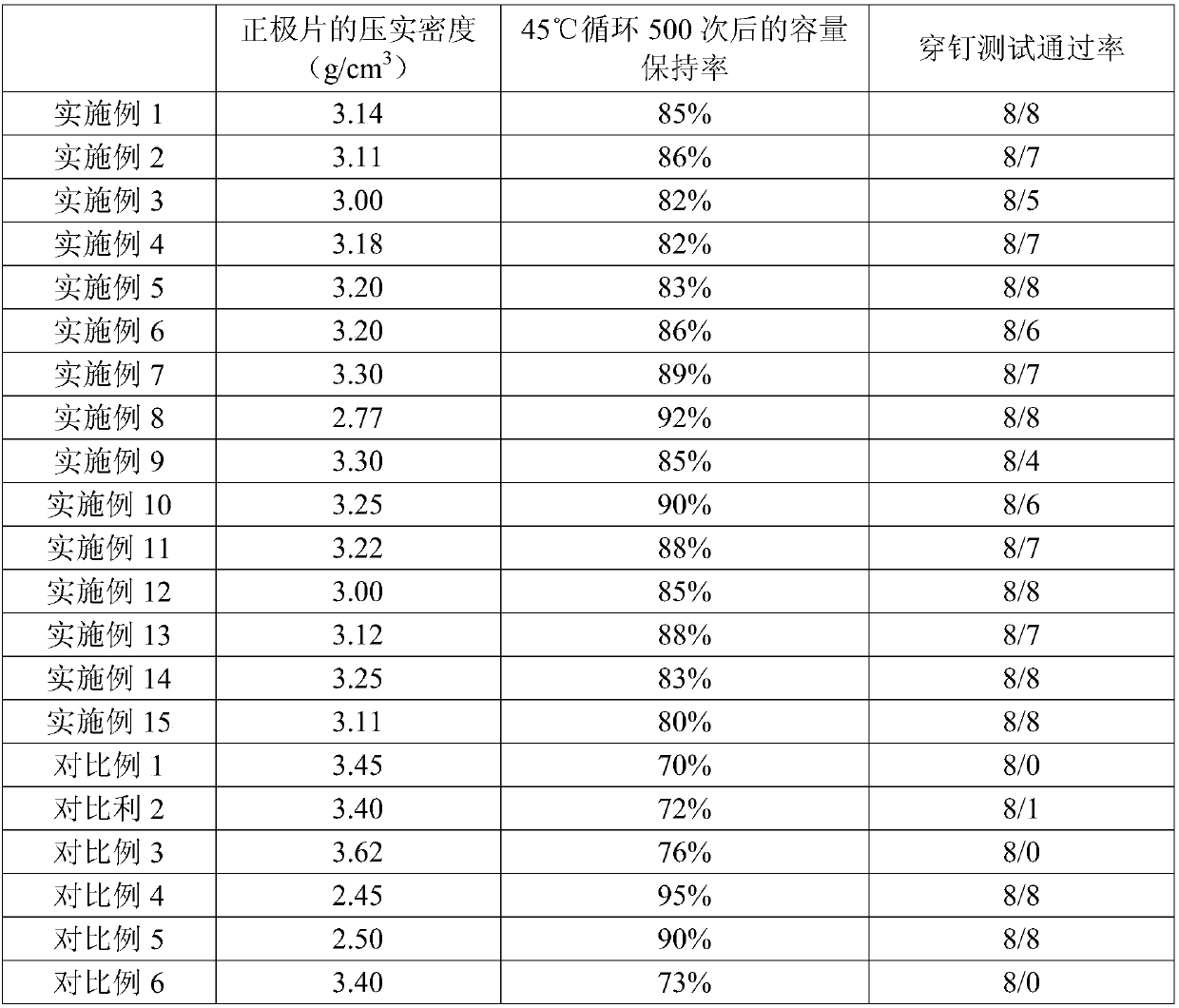

Embodiment 1

[0045] (1) Preparation of positive electrode sheet

[0046] LiNi with secondary particle structure 0.8 co 0.12 mn 0.08 o 2 and LiNi with single crystal grain structure 0.8 co 0.12 mn 0.08 o 2 The first positive electrode active material formed by mixing at a mass ratio of 7:3 is uniformly mixed with the binder polyvinylidene fluoride (PVDF) and the conductive agent conductive carbon (Super-P), and then the solvent N-methylpyrrolidone (NMP) is added , to obtain the first positive electrode slurry after stirring and mixing. Among them, the solid mass ratio of the first positive electrode active material, Super-P and PVDF is 95:2.5:2.5, and the LiNi with the secondary particle structure 0.8 co 0.12 mn 0.08 o 2 The particle size is 11μm, LiNi with single crystal particle structure 0.8 co 0.12 mn 0.08 o 2 The particle size is 3 μm, and the solid content of the first positive electrode slurry is 70%.

[0047] The olivine-type lithium iron phosphate (LiFePO 4 ) and t...

Embodiment 2

[0059] The preparation process of lithium ion battery is the same as embodiment 1, the difference is that,

[0060] (1) Preparation of positive electrode sheet

[0061] The first cathode active material consists of LiNi with secondary particle structure 0.8 co 0.12 mn 0.08 o 2 and LiNi with single crystal grain structure 0.8 co 0.12 mn 0.08 o 2 Formed by mixing at a mass ratio of 8:2;

[0062] The compacted density of the positive electrode sheet is 3.11g / cm 3 ;

[0063]By controlling the coating weight of the first positive electrode slurry and the second positive electrode slurry, the total reversible capacity ratio of the first positive electrode active material and the second positive electrode active material per unit area of the final positive electrode film is 3.2:1;

[0064] The resting time, drying temperature and cold pressing pressure of the first positive electrode slurry and the second positive electrode slurry are reasonably controlled, so that the th...

Embodiment 3

[0066] The preparation process of lithium ion battery is the same as embodiment 1, the difference is that,

[0067] (1) Preparation of positive electrode sheet

[0068] The first cathode active material consists of LiNi with secondary particle structure 0.8 co 0.12 mn 0.08 o 2 and LiNi with single crystal grain structure 0.8 co 0.12 mn 0.08 o 2 Formed by mixing at a mass ratio of 9:1;

[0069] The compacted density of the positive electrode sheet is 3.00g / cm 3 ;

[0070] By controlling the coating weight of the first positive electrode slurry and the second positive electrode slurry, the total reversible capacity ratio of the first positive electrode active material and the second positive electrode active material per unit area of the final positive electrode film is 3.2:1;

[0071] The resting time, drying temperature and cold pressing pressure of the first positive electrode slurry and the second positive electrode slurry are reasonably controlled, so that the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com