Air horn solenoid valve

A solenoid valve and air horn technology, applied in the field of solenoid valves, can solve the problems of low service life, coil open circuit, low protection level, etc., and achieve the effects of reducing product cost, prolonging service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

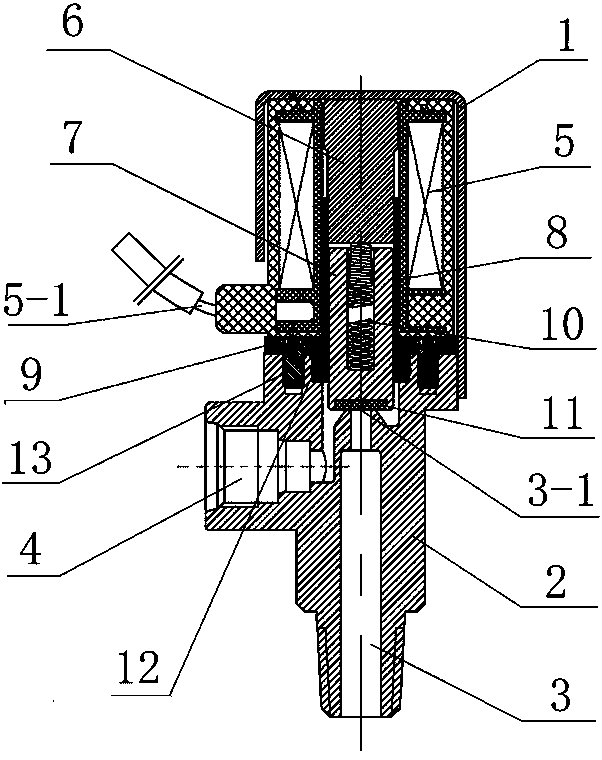

[0033] The present invention as Figure 1 to Figure 3 Shown:

[0034] An air horn solenoid valve, including a valve body, a coil assembly 5, a static valve core 6 and a moving valve core 7, wherein: the valve body includes a casing 1 and a base 2, the bottom of the base 2 is axially provided with an air outlet 3, and the air outlet The inner end of 3 is provided with a sealing end surface 3-1, the inner end of the air outlet 3 is provided with a valve core movement chamber, and the side wall of the valve core movement chamber is provided with an air inlet 4, and the air inlet 4 and the air outlet 3 move through the valve core The cavity is connected; the coil assembly 5 is located above the base 2, the coil assembly 5 includes a skeleton and a coil, the exterior of the coil assembly 5 is integrally sealed, and the lead wire 5-1 is integrated with the coil assembly 5;

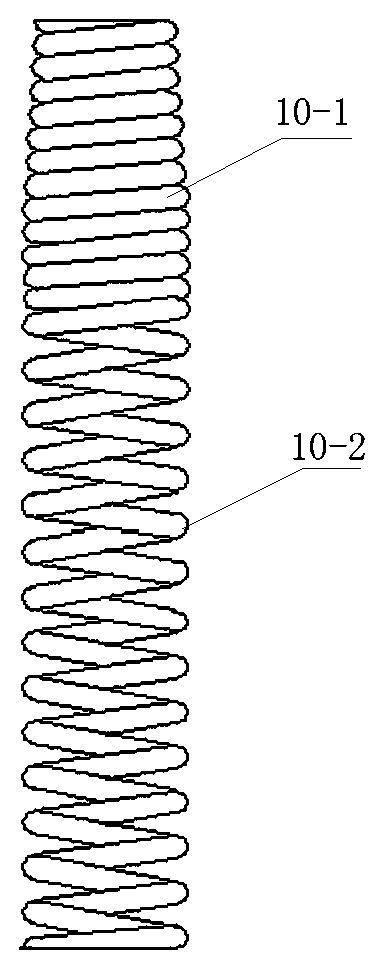

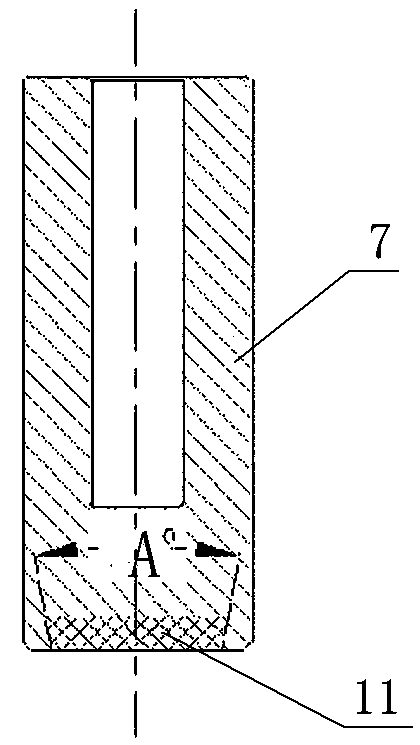

[0035] A spool mounting cavity is axially provided in the frame of the coil assembly 5, and the spool mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com