Compaction construction device for bituminous concrete pavement, and construction method

A technology of asphalt concrete and construction equipment, which is applied in the field of building construction, can solve the problems of low construction efficiency, heavy work of construction personnel, and high price, and achieve the effects of simple structure, improved construction efficiency, and reduced physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

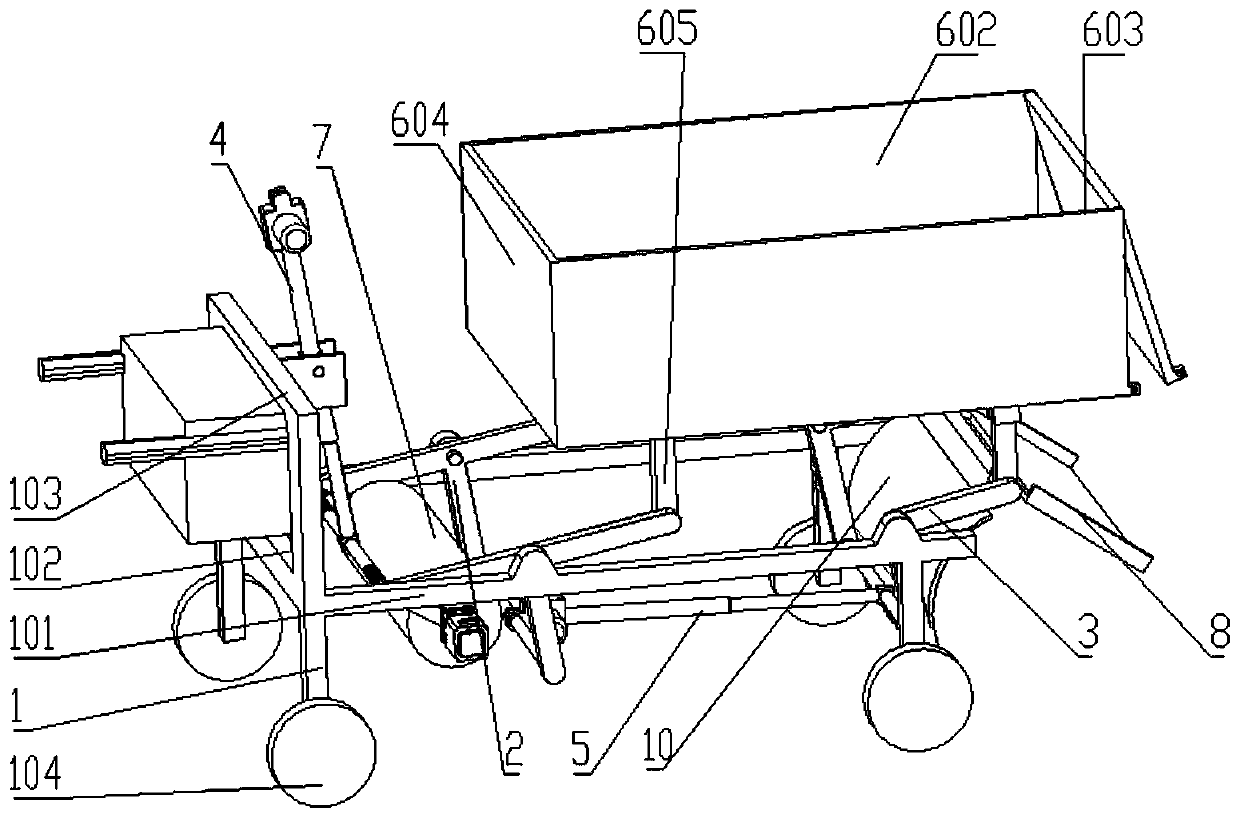

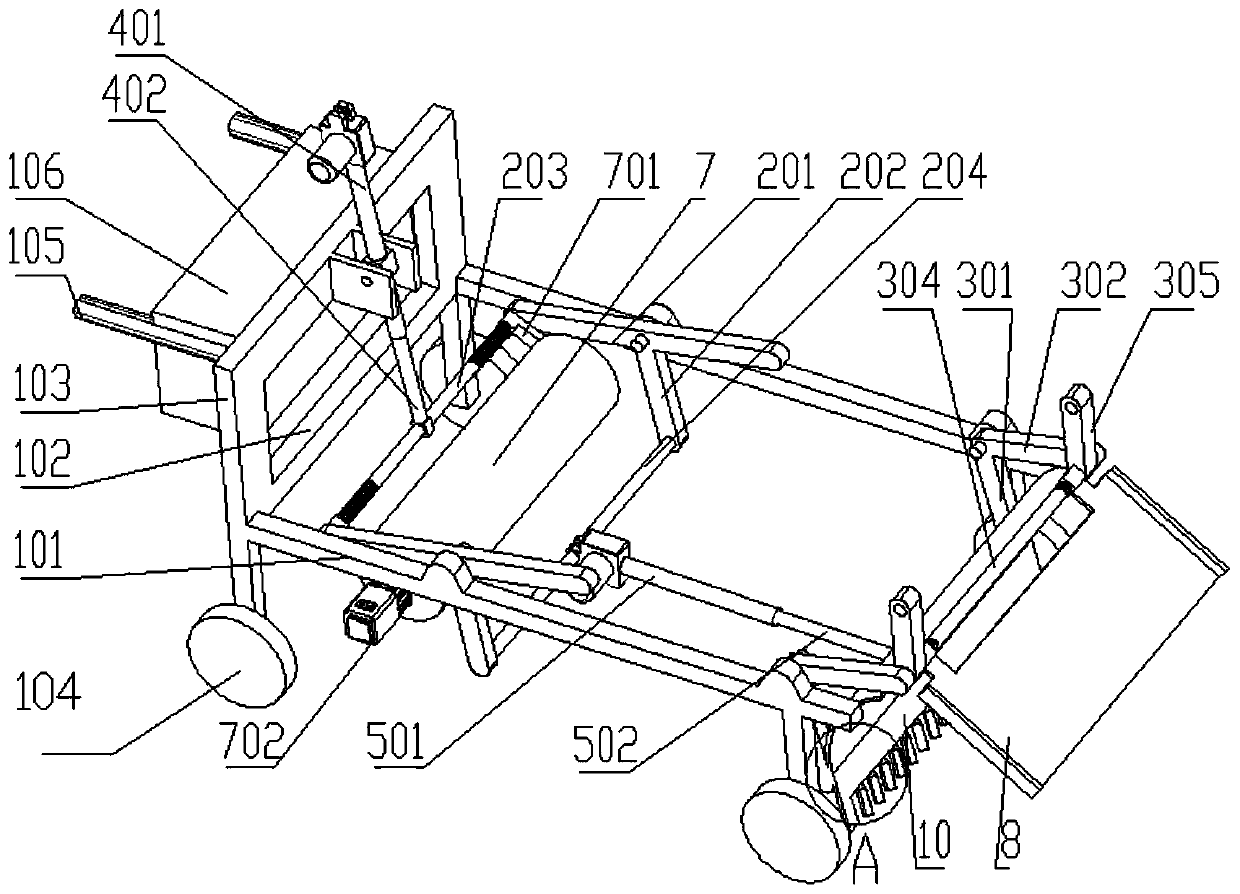

[0038] see Figure 1-Figure 7, a rolling construction device for asphalt concrete pavement, including a vehicle frame 1 provided with wheels 104, the vehicle frame 1 includes two symmetrically arranged longitudinal beams 101, one end of the two longitudinal beams 101 is connected by a crossbeam 102, and the top of the crossbeam 102 is arranged There is a vertical plate 103, which also includes a connecting frame one 2 and a connecting frame two 3 arranged between the two longitudinal beams 101, and the connecting frame one 2 is close to the vertical plate 103;

[0039] Connecting frame one 2 comprises two T-bars and cylindrical bar one 203 and cylindrical bar two 204 that connect two T-bars, T-bar comprises horizontal bar 201 and is arranged on the vertical bar 202 of horizontal bar 201 middle positions, two One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com