Roller bed conveyor device based on tray anti-reversing

An anti-backward and conveyor technology, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of high replacement cylinder costs, high production costs, and high maintenance costs, and achieve low production costs and long service life. , the effect of not consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

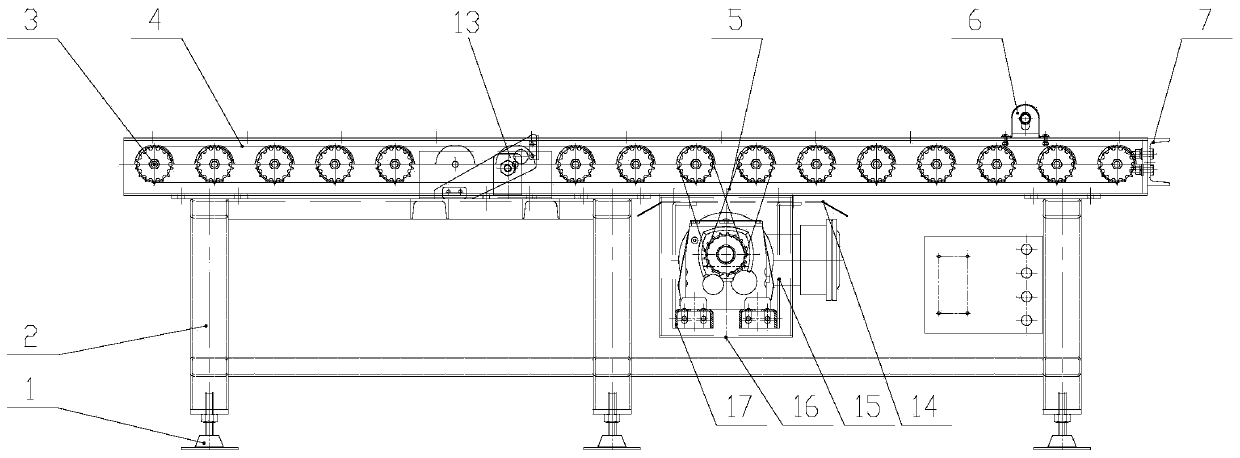

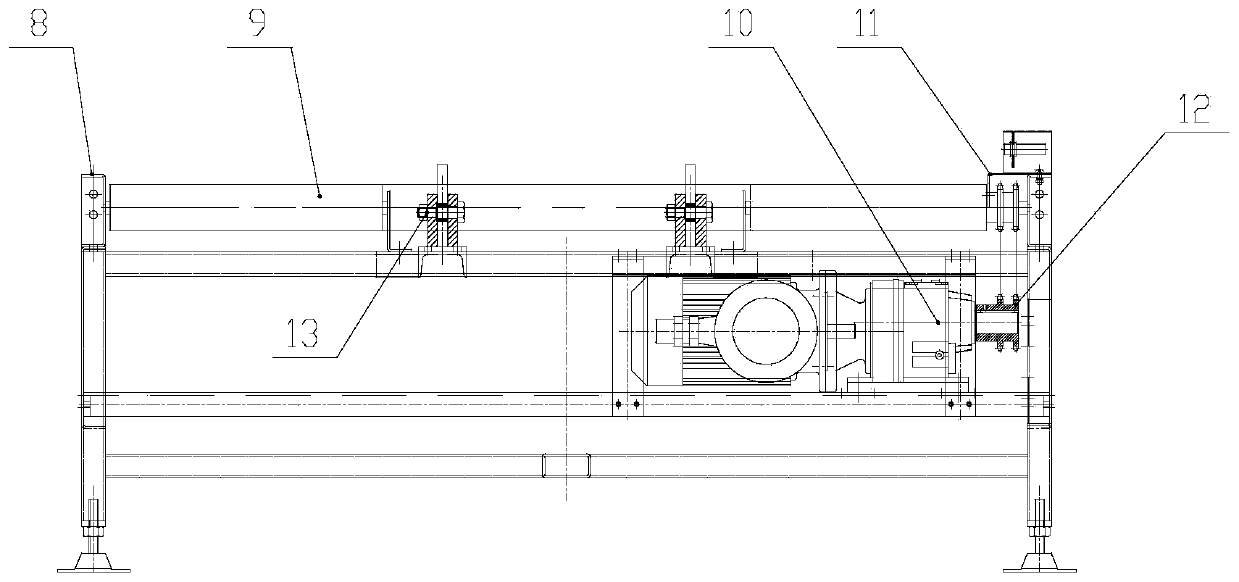

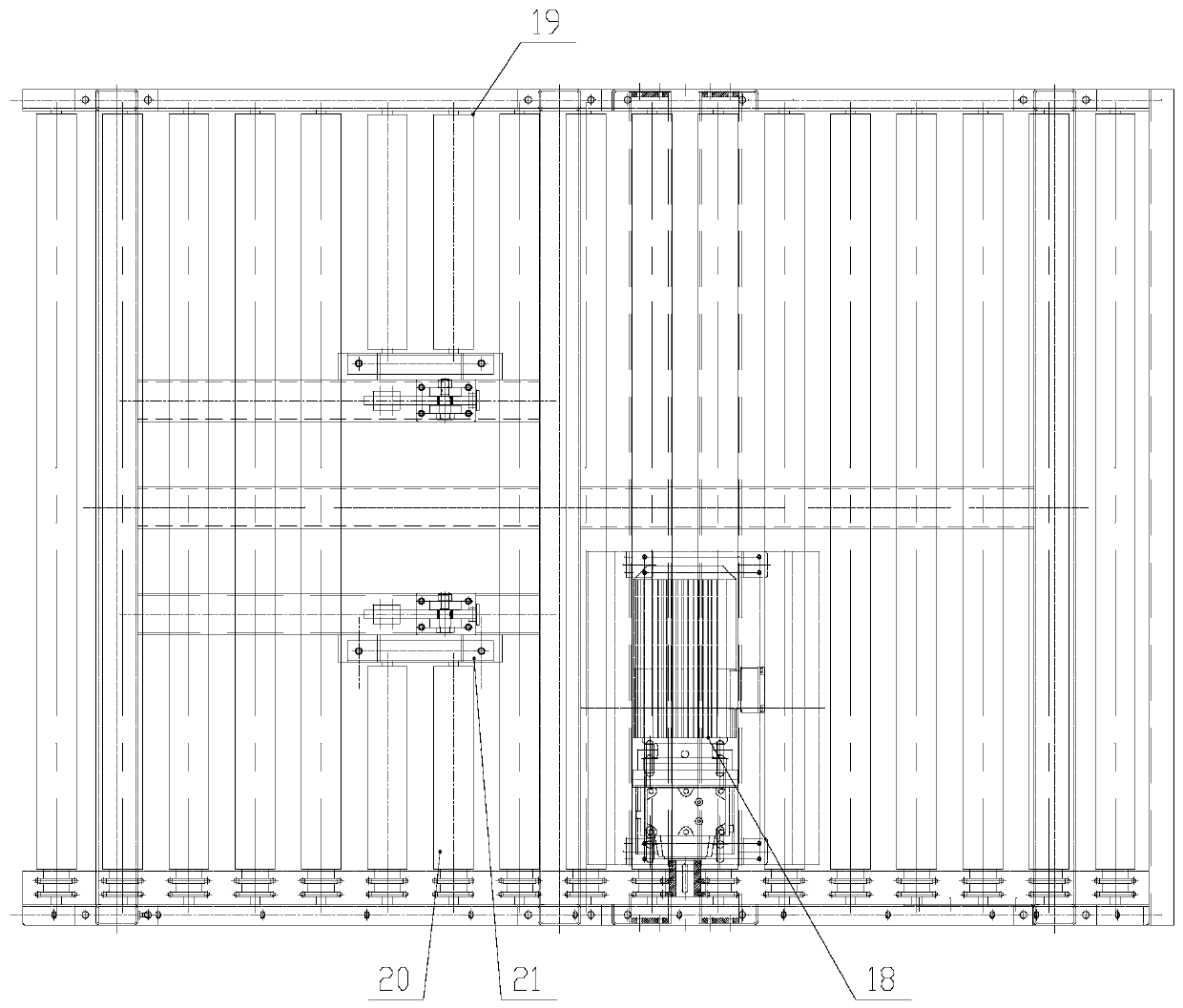

[0020] Figure 1~7 Among them, including foot cup 1, roller machine bracket 2, hexagon socket screw 3, chain 4, right side plate 5, light detection sensor 6, end baffle 7, left side plate 8, long power roller 9, power shaft 9-1, the retaining ring for the first hole 9-2, the first deep groove ball bearing 9-3, the retaining ring for the second hole 9-4, the second deep groove ball bearing 9-5, the third deep groove ball bearing 9-6, bearing seat 9-7, reducer 10, cover plate 11, sprocket 12, intermediate baffle assembly 13, hex nut 13-1, mounting bracket 13-2, intermediate baffle 13-3, copper sleeve 13 -4. Connecting bolts 13-5, first weight block 13-6, second weight block 13-7, dust cover 14, reducer bracket 15, reducer mounting plate 16, reducer mounting beam 17, motor reducer 18. Unpowered roller 19, short powered roller 20, short side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com