New anti-failure damper and its installation method

A damper and anti-failure technology, which is applied in the direction of transportation and packaging, forced railway car stoppers, railway car body parts, etc., can solve the problems of friction disc damper clamping force reduction, damper failure, rail deformation and wear, etc. Achieve the effects of reducing the number of dampers arranged, improving the safety protection level, and reducing the distance occupied by lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

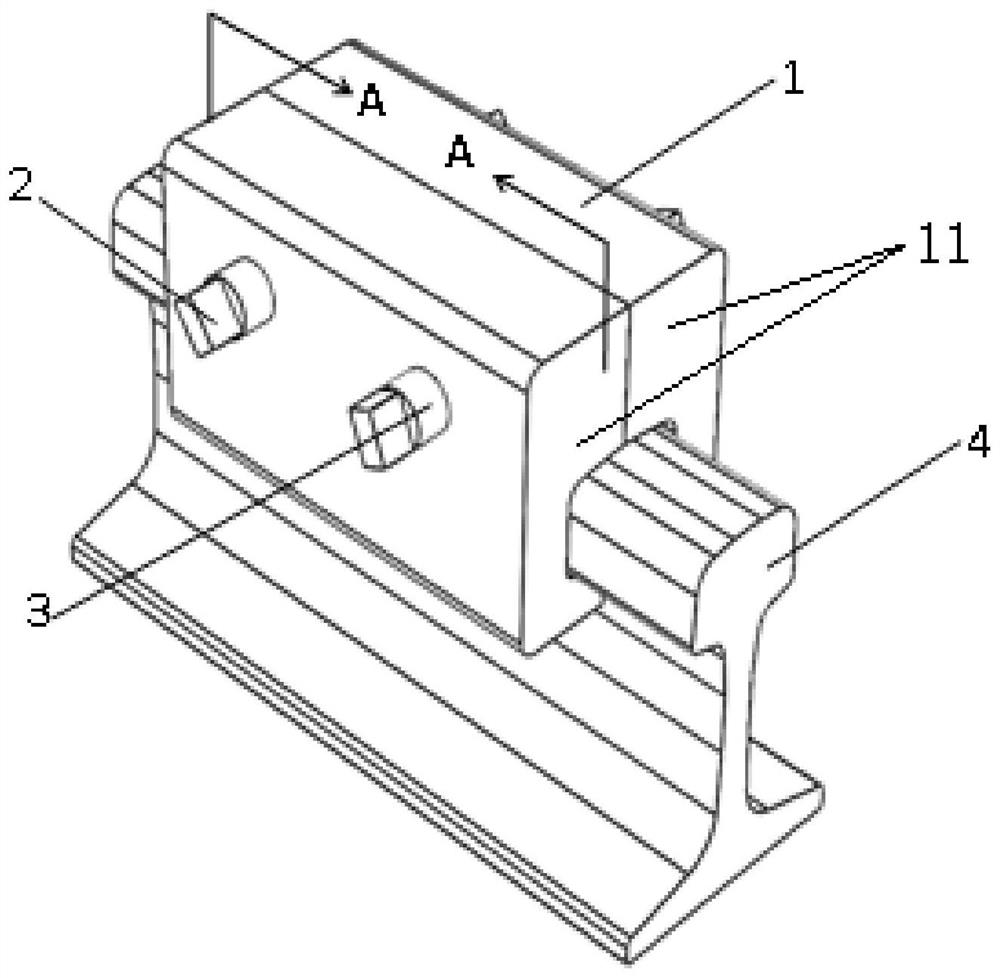

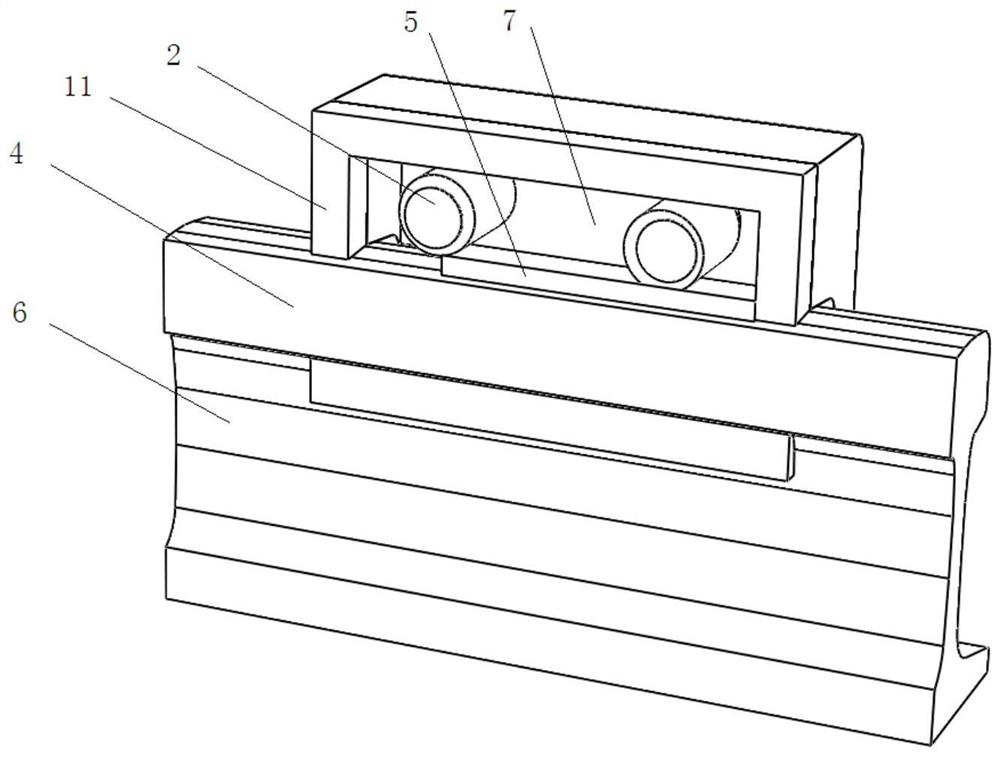

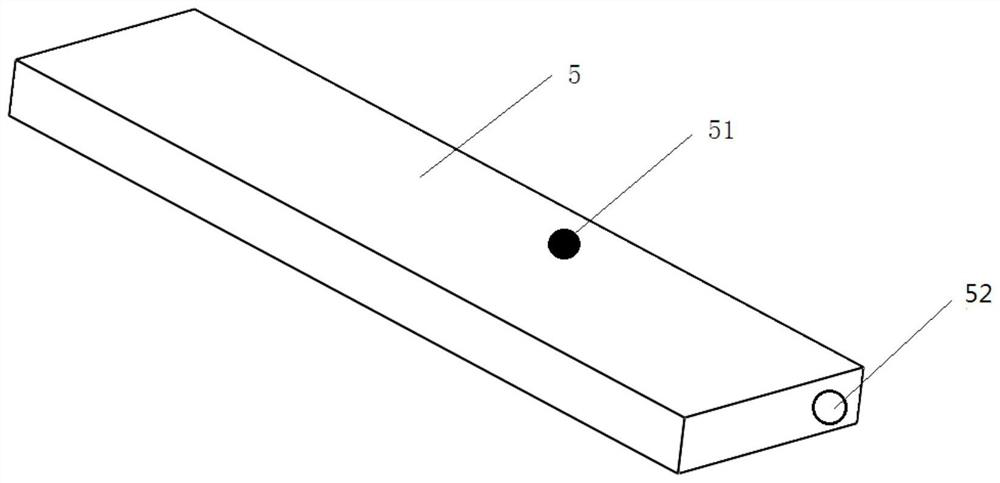

[0064] As shown in the figure, the present invention provides a new type of anti-failure damper. The friction plate 5, two half boxes 11 and eccentric body bolts 2 are assembled on the rail according to the instructions of the installation marks 52 to ensure the damping on the box 1. Arrow 111 in the sliding direction of the damper is the sliding direction of the damper.

[0065] After docking the two half-boxes 11, lock the eccentric body bolt 2 to prevent it from deflecting, and start pre-tightening the nut 3;

[0066] Use a torque wrench to apply torque to the eccentric body bolt 2, so that the eccentric body 21 presses the friction plate, and further locks the nut 3;

[0067] When the damper is pushed by the sliding car stopper or the front damper, one end of the box body 1 of the hit damper starts to be stressed and starts to move, and as a friction body, after receiving the force of the rail surface, it will After sliding, the eccentric body bolt 2 is driven to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com