Antenna cover plate profiling prefabricated member puncture method and antenna cover plate forming method

A prefabricated part and antenna cover technology, which is applied in the field of antenna cover molding and antenna cover profiling prefab puncture, can solve the problems of low overall strength and weak force on the radome cover, so as to avoid unbalanced force. , high overall strength and performance, the effect of reducing the amount of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

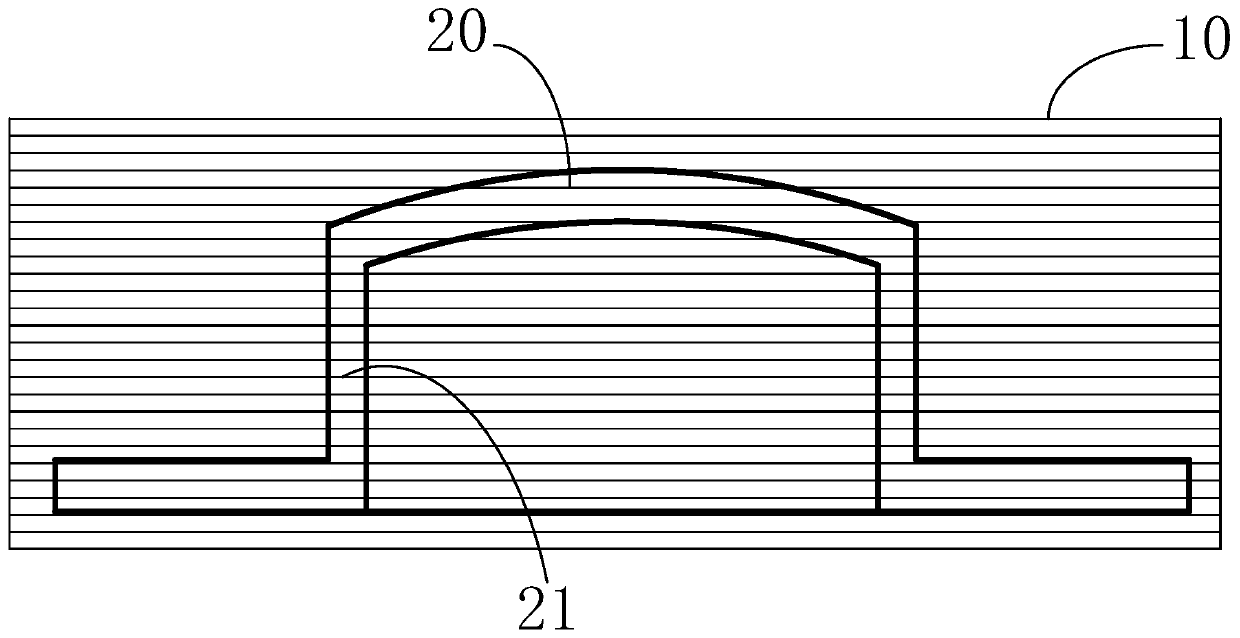

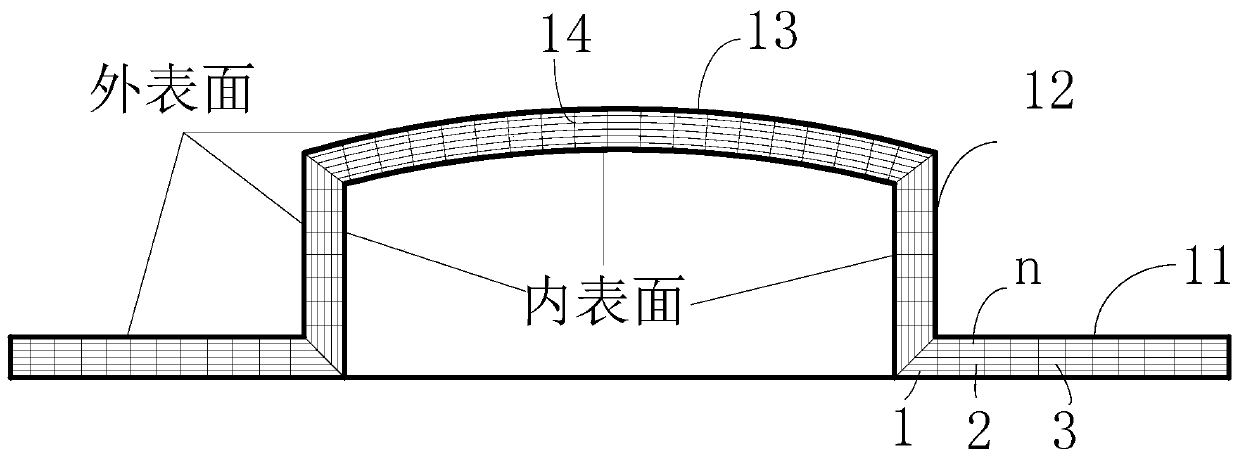

[0032] as attached figure 2 Shown, a kind of puncture method of profiling prefabricated part of antenna cover plate, comprises the following steps:

[0033] S1, continuously laying a layer of fiber cloth on the outer surface of the mold;

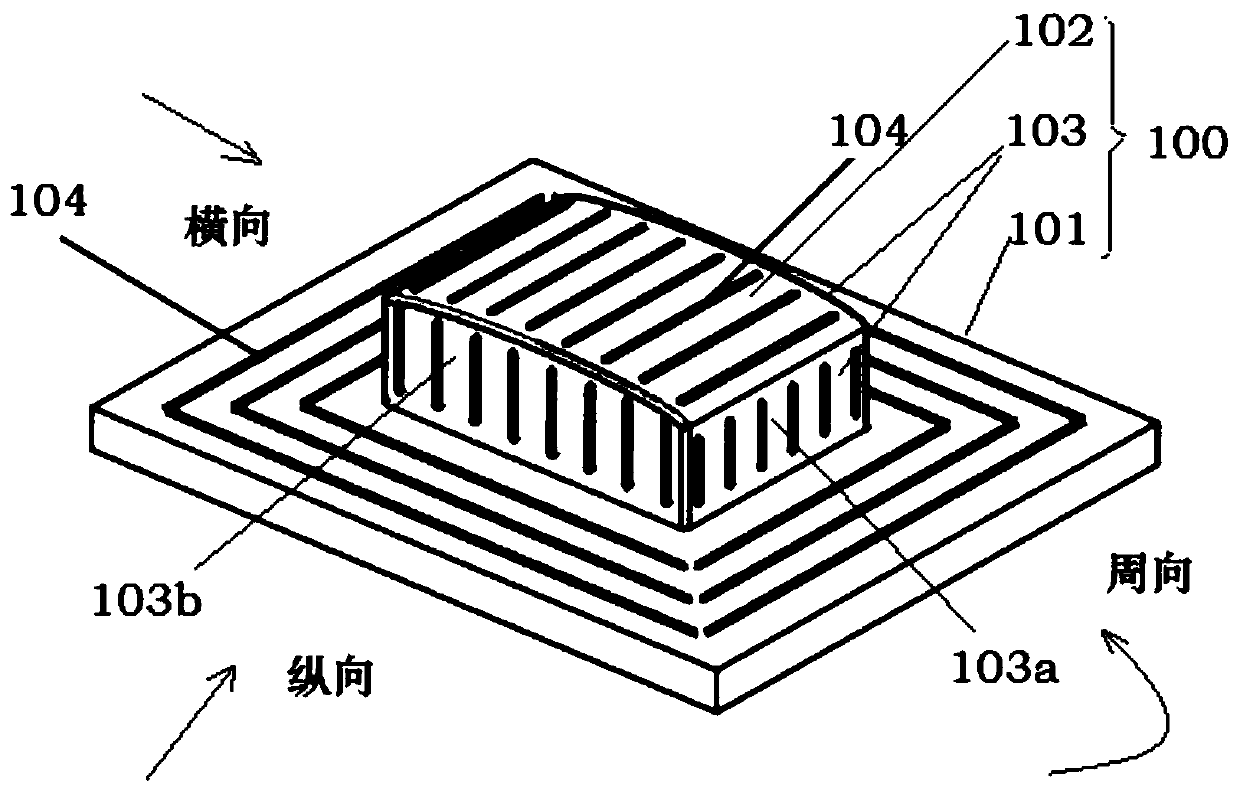

[0034] The fiber cloth is made of woven cloth layer, which is formed by two-way fiber weaving. The fiber cloth is covered on the mold, and the center position is aligned with the center of the raised top surface of the mold to reduce the waste of raw materials.

[0035] S2, adjusting the fiber gap of the fiber cloth on the raised part of the mold so that the fiber cloth coincides with the outer surface of the mold and forms a fiber cover;

[0036] This process can be adjusted manually or through the mold. Yes, the fiber cloth is deformed by the gap between the vertical and horizontal fibers. After deformation, a three-dimensional fiber cover is formed. The fiber cover here covers the outer surface of the mold as a whole. And it is the sam...

Embodiment 2

[0074] Based on the first embodiment above, the embodiment of the present invention also provides a method for forming an antenna cover, including the following steps:

[0075] The preform is prepared by the puncture method of the profiling preform of the antenna cover plate in any of the above embodiments;

[0076] Use two rigid molds to clamp both sides of the prefabricated part in the thickness direction, and adjust the gap between the two rigid molds according to the control margin to control the thickness of the prefabricated part within the preset range; The gap between the rigid molds, until the preform reaches the pre-controlled thickness, the common way to fix the inner rigid mold, apply pressure to the outer rigid mold, when the pre-controlled thickness range is reached, fix the inner and outer rigid molds (such as bolt connection and other methods) , to maintain a gap between the two to control the preform thickness;

[0077] Put the two rigid molds and the preform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com