Efficient winnowing material flotation equipment

An air separation and high-efficiency technology, which is applied in solid separation, food science, and separation of solids from solids by air flow. It can solve the problems of air separation efficiency and air separation accuracy of a single device, and improve flotation efficiency. , the effect of expanding the flotation chamber and enhancing the practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

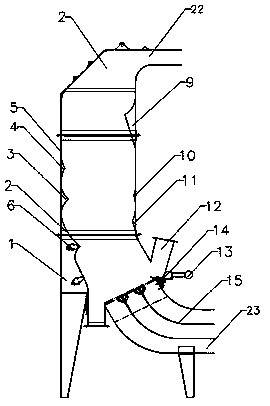

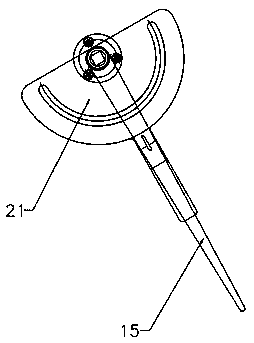

[0028] Figure 1-Figure 4 It shows: a high-efficiency air separation material flotation equipment, including a shell 1, a flotation chamber, an air supply device and a throwing device, the shell 1 is a rectangular cavity structure, and the shell 1 is internally set There is a flotation chamber, and the flotation chamber is divided into three flotation chambers; and the flotation chambers are respectively provided with air guiding devices, and the air guiding devices include a fixed plate 5, a second throwing plate 2, a third The material throwing plate 3 and the fourth material throwing plate 4; the bottom of the housing 1 is provided with an air inlet duct 23, and the junction of the air inlet duct 23 is provided with an isolation net, and the lower part of the isolation net is provided with an air supply device. The wind device includes an air supply guide plate 15 and a handle 21 connected with the air supply guide plate 15, the air supply guide plate 15 is movably connecte...

Embodiment 2

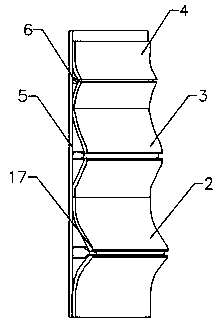

[0030] This embodiment further explains the air guide device on the basis of specific embodiment 1, the fixed plate 5 of the air guide device is movably arranged in the first flotation chamber of the flotation chamber, and the fixed plate 5 It is movably connected with the bottom of the first flotation chamber; the fixed plate 5 is provided with the second throwing plate 2, the third throwing plate 3 and the fourth throwing plate 4 from bottom to top; the other side of the shell 1 Air guide plate 9 and material guide plate 11 are provided, and air guide plate 9 and material guide plate 11 are arranged correspondingly with material throwing plate; Air guide plate 9 and air guide plate 11 are arranged on a plurality of flotation chamber inner walls, can Diverting the air flow and adjusting the position of the cyclone in the flotation chamber ensures that the material can be flotation under the best wind field, effectively improving the flotation efficiency and enhancing the pract...

Embodiment 3

[0032]This embodiment further explains the air guide device on the basis of the specific embodiment 1. The three throwing plates of the air guide device have arc-shaped board surfaces, and the middle part of the throwing plate is provided with a flexible The air throwing device, the flexible air throwing device is composed of a vent 17 and a nozzle 6, the vent 17 is located between two throwing plates, and the vent 17 is provided with an air duct, and the air duct is provided with A number of nozzles 6; flexible air-throwing nozzles are arranged in the middle of the first throwing plate 2, the second throwing plate 3 and the third throwing plate 4 of the air guide device, which can reversely lead out the airflow and provide reverse flow for the flotation chamber. The airflow generates a cyclone, and the material is longitudinally flotation by the cyclone, the unqualified material is taken away from the bottom outlet, and the qualified material is exported from the upper part. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com