Method and device for recovering acetylene from displacement exhaust gas of acetylene generator

A technology for acetylene generators and gas storage devices, which is applied to acetylene generators, parts of acetylene gas generators, chemical instruments and methods, etc., and can solve the problem of poor adsorption effect of adsorbents, failure to meet emission standards, and low pressure of replacement exhaust gas and other problems, to achieve the effect of large operating flexibility, improving the social benefits of the factory, and less corrosiveness of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

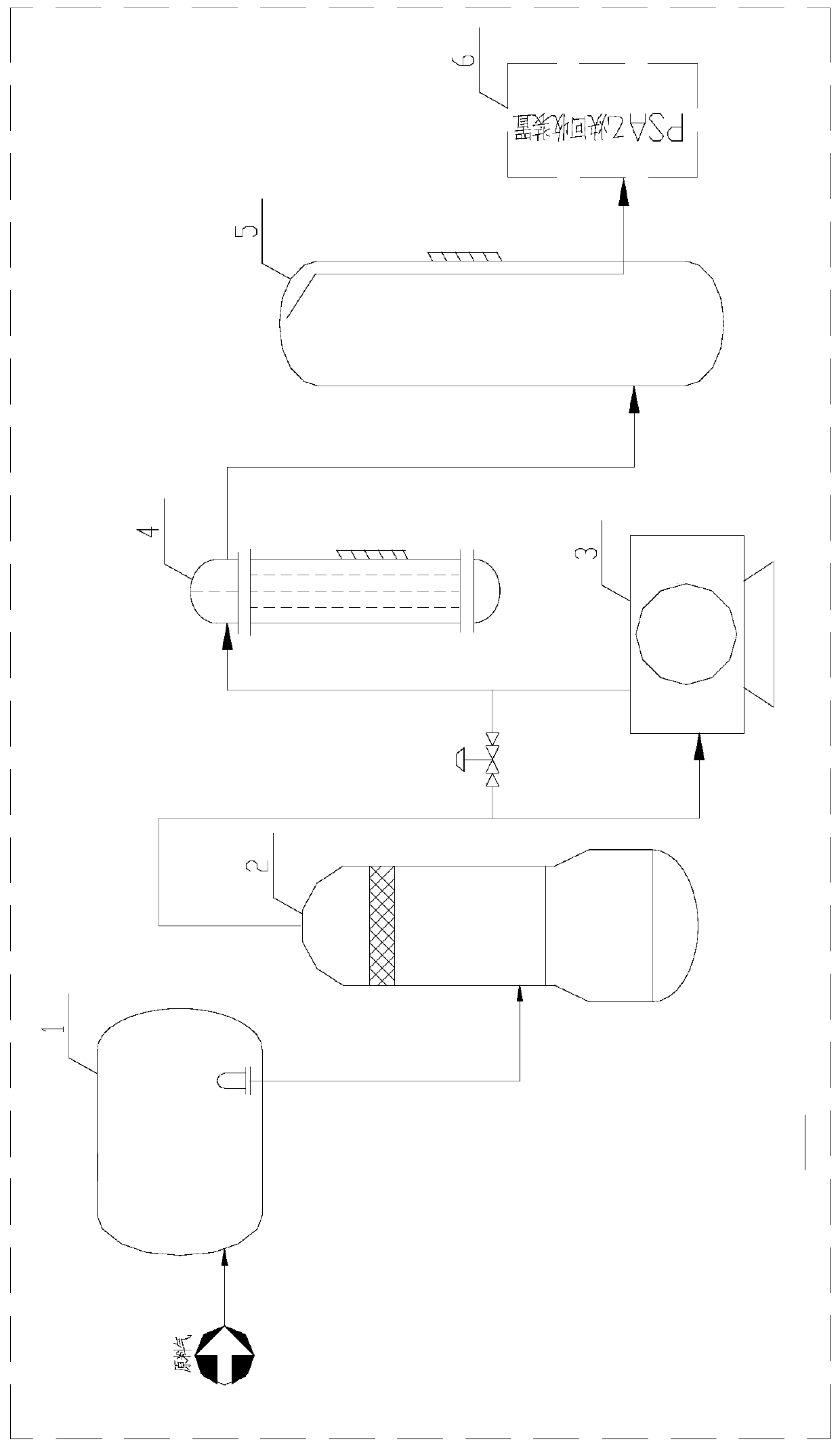

[0047] A method for recovering acetylene from acetylene generator replacement exhaust gas, using the device in the specific embodiment, specifically comprising the following steps:

[0048] The adsorption working pressure of the device is about 0.18Mpa, and the gas volume is 500Nm 3 / h or so, the composition of the exhaust gas replaced by the acetylene generator is shown in Table 1 below:

[0049] Table 1 acetylene generator replacement waste gas composition list

[0050] components C 2 h 2

O 2

N 2

Σ Volume content (%) 15 ~0.5 ~84.5 100

[0051] After the device is in operation, the raw gas enters the gas storage device under normal pressure, and a distance sensor is installed on the top of the gas storage device to monitor the amount of gas storage in real time. The raw gas comes out of the gas storage device and enters the dust removal device to remove dust.

[0052] The raw material gas after dedusting enters the compressor to be ...

Embodiment 2

[0058] A method for recovering acetylene from acetylene generator replacement waste gas, using the device in the specific embodiment, specifically comprising the following steps:

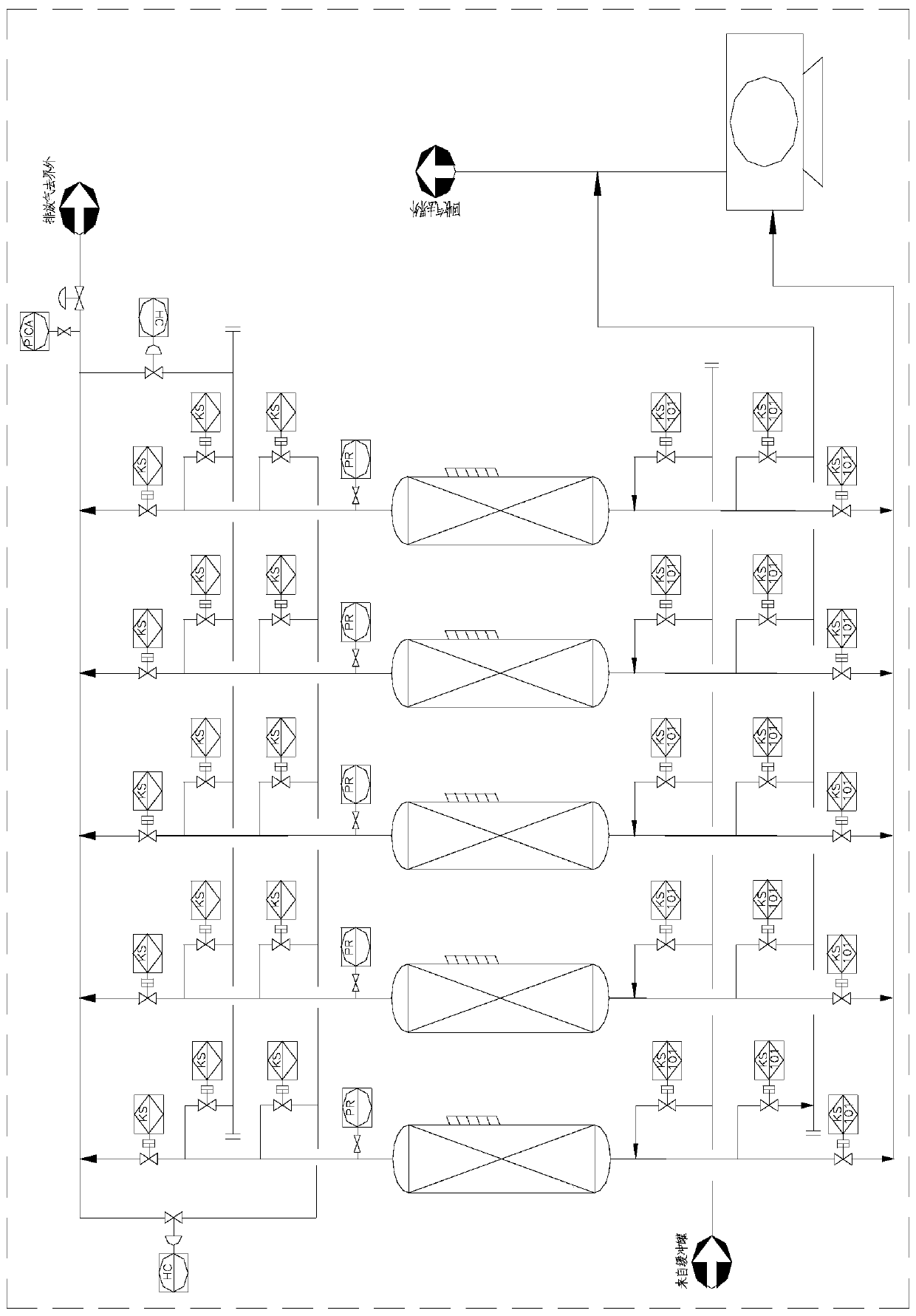

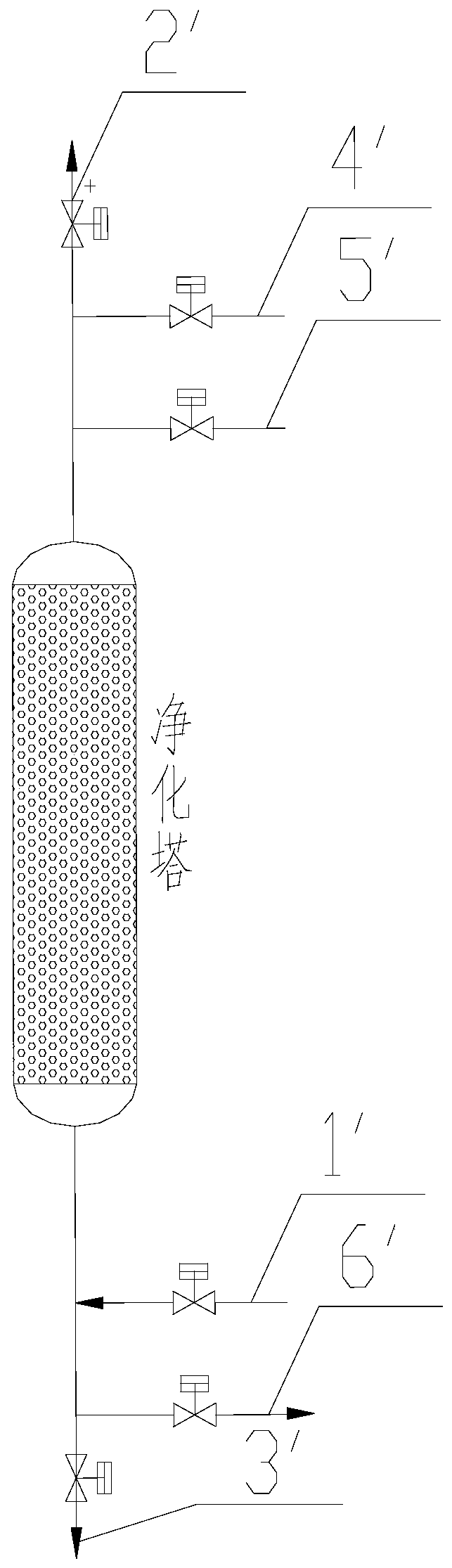

[0059] In this example, the adsorption working pressure of the device is 0.25Mpa, and the gas volume is 1500Nm 3 There are 8 purification towers per hour, and each purification tower is connected in parallel, and each purification tower is connected by a pipeline and a program-controlled valve; each purification tower needs to undergo adsorption and pressure reduction when purifying and recycling the material gas There are six steps: evacuation, evacuation and flushing, pressure boost and final boost. The composition of the waste gas replaced by the acetylene generator is shown in Table 2 below:

[0060] Table 2 acetylene generator replacement waste gas composition list

[0061]

[0062]

[0063] After the device is in operation, the raw gas enters the gas cabinet at about 3Kpa, enters the c...

Embodiment 3

[0067] A method for recovering acetylene from the replacement waste gas of the acetylene generator, adopting the operation steps as described in Example 2, wherein 3 purification towers are configured. The raw material gas composition is as shown in the table of embodiment 2, the working pressure of the purification tower is 0.15Mpa, and the raw material gas volume is about 150Nm3 / h. The gas storage device is an air storage bag with a volume of 100m 3 , The raw material gas enters the air storage bag for buffering under normal pressure, and the dust in the exhaust gas is removed by washing with water, and then pressurized to 0.15Mpa. After being buffered by the buffer tank, it enters the purification tower to recover the effective component acetylene. After being treated by the device of this example, the recovery rate of acetylene in the raw gas reaches 99.9%, and the total non-methane hydrocarbon content in the purified gas is less than 20mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com