Side brush assembly, cleaning robot and moving method of cleaning robot

A cleaning robot and side brush technology, which is applied to robot cleaning machines, cleaning machines, carpet cleaning, etc., can solve problems affecting the smooth movement of cleaning robots, and achieve the effect of avoiding excessive loss and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

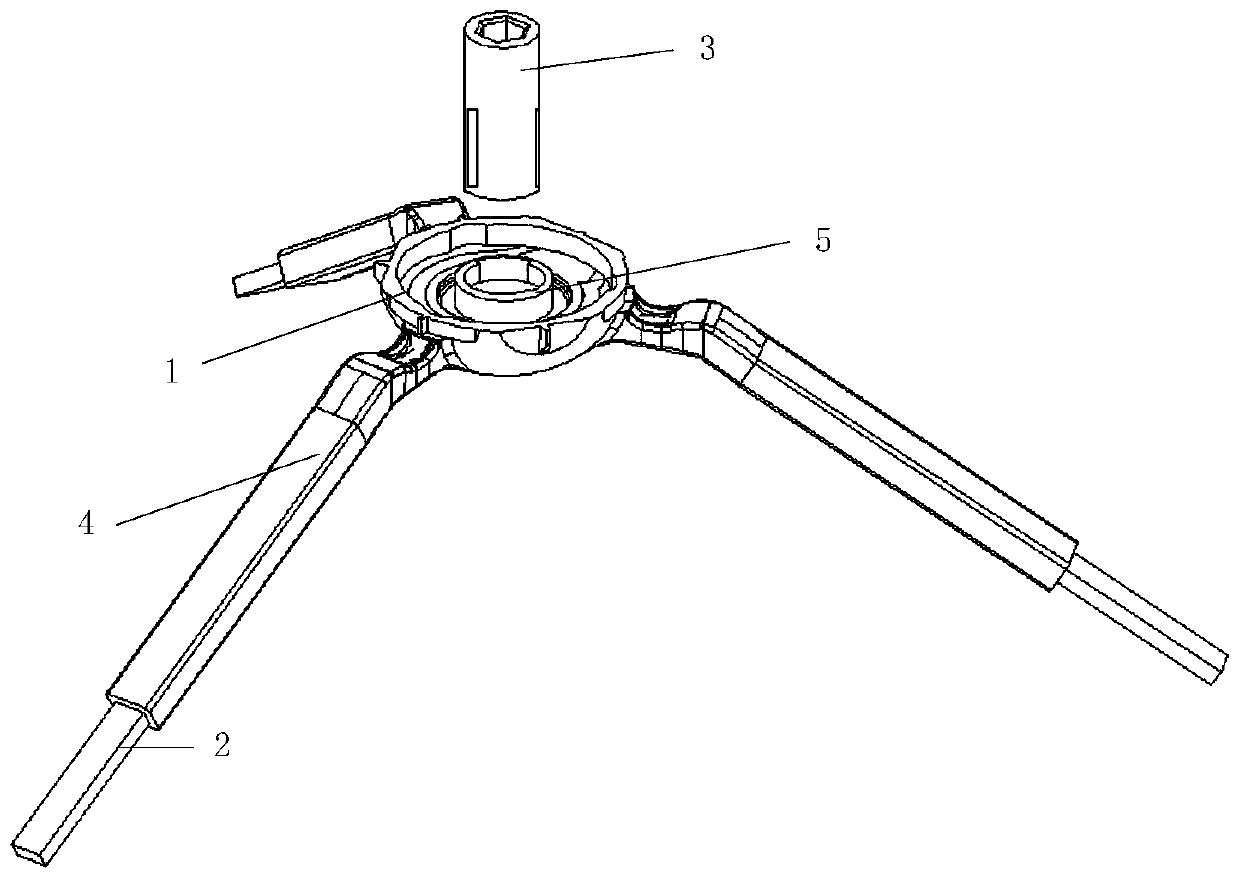

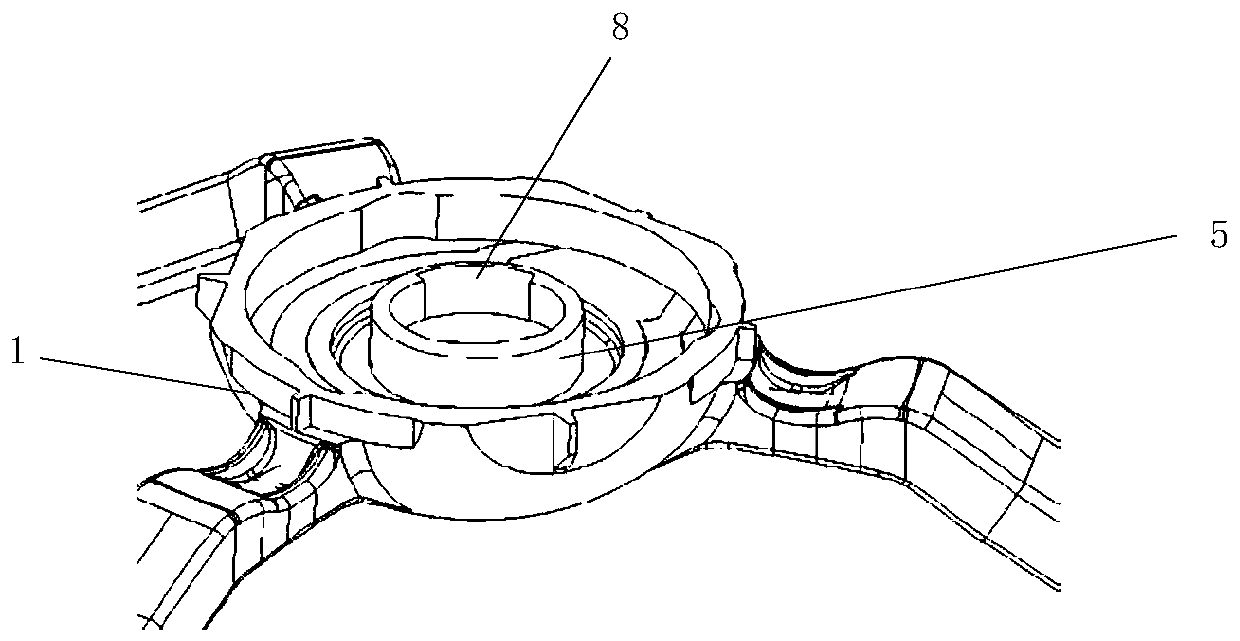

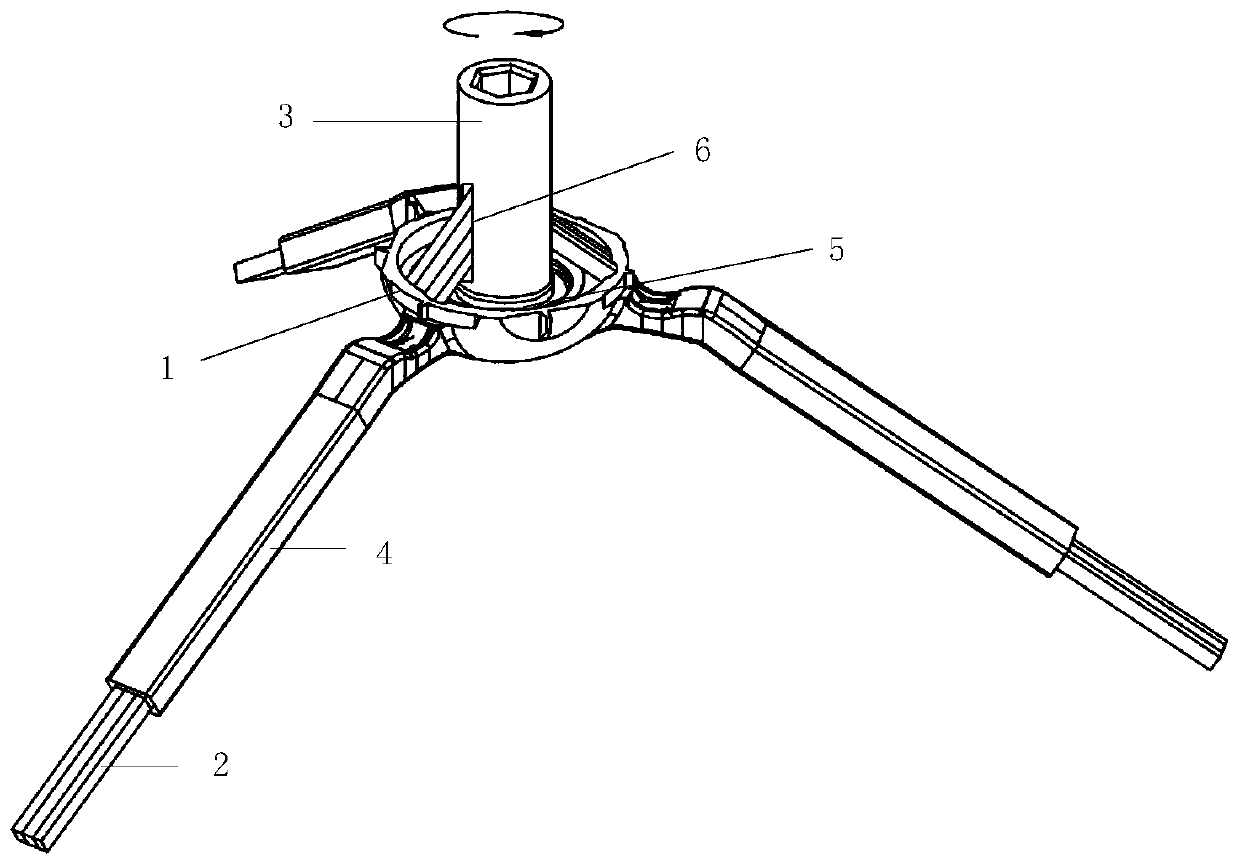

[0055] Such asfigure 1 As shown, the embodiment of the present invention provides a side brush assembly, which includes a side brush body 1, a side brush motor and bristles 2; The fixed parts; the bristles 2 are arranged in the bristle accommodating part; the side brush motor can drive the bristles 2 to protrude and / or retract from the bristle accommodating part, and the side brush motor can drive the side brush body 1 to rotate. When the cleaning robot needs to move, the side brush motor drives the bristles 2 into the bristle accommodation, so that the bristles 2 are separated from the working surface. When the cleaning robot needs to perform cleaning operations, the side brush motor drives the bristles 2 to protrude from the bristle accommodation. The bristles 2 are in contact with the working surface again, and at the same time, the side brush motor drives the side brush body 1 to rotate, so that the bristles 2 rotate with the side brush body 1 for cleaning operations. It s...

Embodiment 2

[0072] An embodiment of the present invention provides a cleaning robot, including a side brush assembly. For the side brush assembly, refer to the side brush assembly in Embodiment 1.

[0073] In the embodiment of the present invention, in addition to the basic functions, the cleaning robot can at least move autonomously and does not need to clean the working surface during the moving process. After charging, return to continue the cleaning operation, or stop the current cleaning operation and go to a new operation area, etc.

[0074] Since the moving process of the cleaning robot has a certain degree of automation, in the embodiment of the present invention, the cleaning robot also includes a main control unit; the main control unit structure receives the signal sent by the sensor; the main control unit controls the motion state of the side brush motor. The main control unit may be a part on the cleaning robot that is used solely to control the movement of the cleaning robot...

Embodiment 3

[0076] An embodiment of the present invention provides a method for moving a cleaning robot, and the cleaning robot refers to Embodiment 2.

[0077] This move method includes:

[0078] S1. The main control unit of the cleaning robot generates a side brush control signal and sends it to the side brush assembly.

[0079] The main control unit receives the movement instruction signal, determines the movement target position, and sends a side brush control signal to the side brush assembly.

[0080]It should be noted that the movement indication signal can be a power warning signal, a breakpoint position continuation scan signal, a return to charging stand signal, and a fast movement signal. When the current power in the power supply unit is lower than 15% of the total power and needs to be returned to the charging stand for charging, the power supply unit generates a power warning signal and sends it to the main control unit; when the cleaning robot is cleaning, if the power is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com