Simulated ignition testing method for vehicle

A technology for simulating ignition and testing methods, which is applied in vehicle testing, electrical testing/monitoring, and machine/structural component testing, etc. It can solve software and hardware repair obstacles and troubles, affect safety and function, and the high price of robotic arms. Achieve the effect of saving development cost and cycle and avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

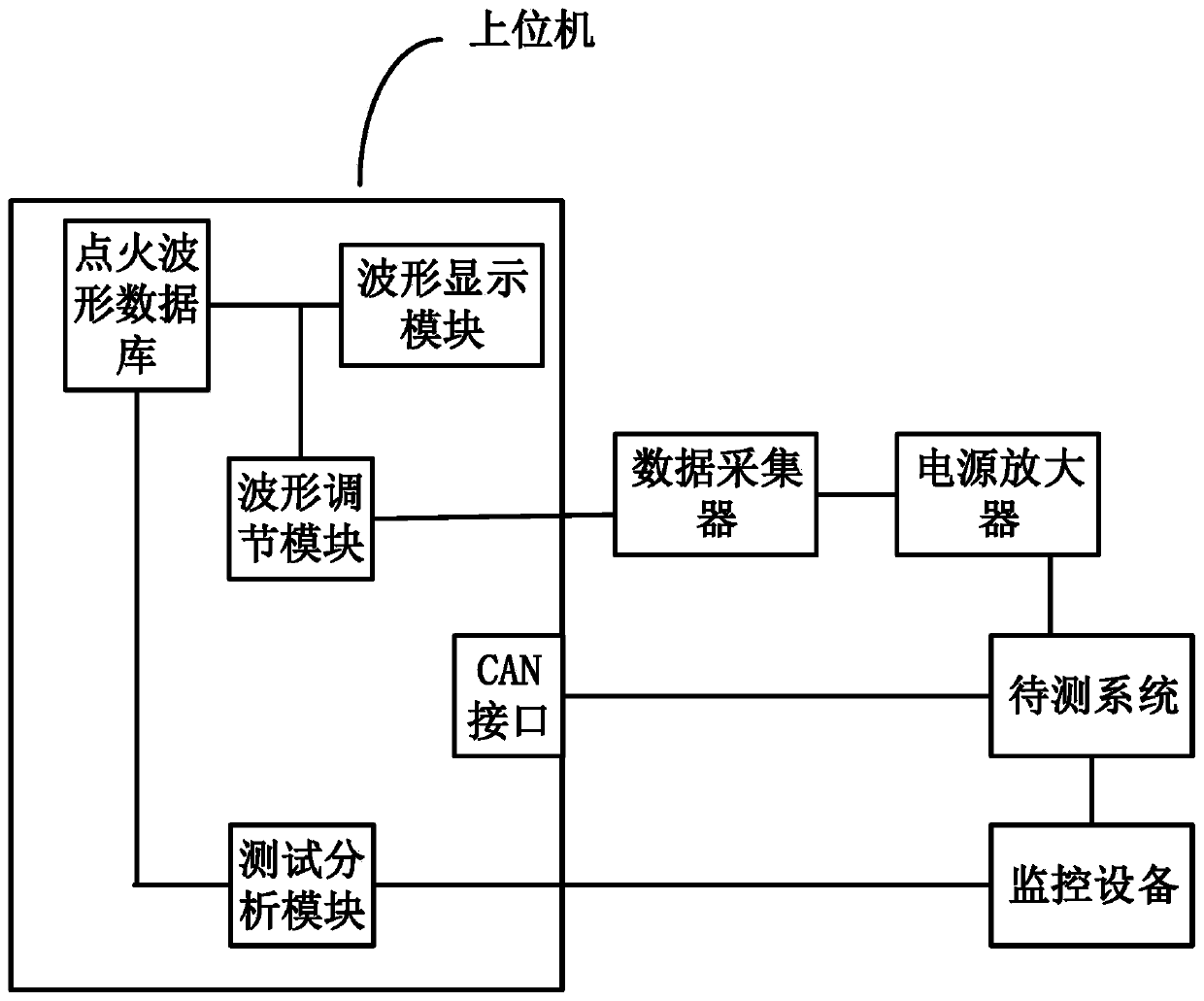

[0038] This implementation provides a simulated ignition test system for vehicles, including a host computer, a data acquisition device (Data Acquisition, DAQ), and a power amplifier. The data acquisition device is connected to the host computer and the power amplifier respectively, and the host computer is used to generate virtual pressure ignition. Waveform signal, the data collector is used to convert the digital signal generated by the host computer into an analog signal and then output it, and the power amplifier is used to adjust the analog signal output by the data collector to adjust the parameters of the output analog ignition waveform.

[0039] The upper computer includes at least: an ignition waveform database, a waveform display module, and a waveform adjustment module;

[0040] an ignition waveform database configured to store ignition waveform data generated by vehicle pressure ignition;

[0041] Specifically, the ignition waveform data includes parameters such a...

Embodiment 2

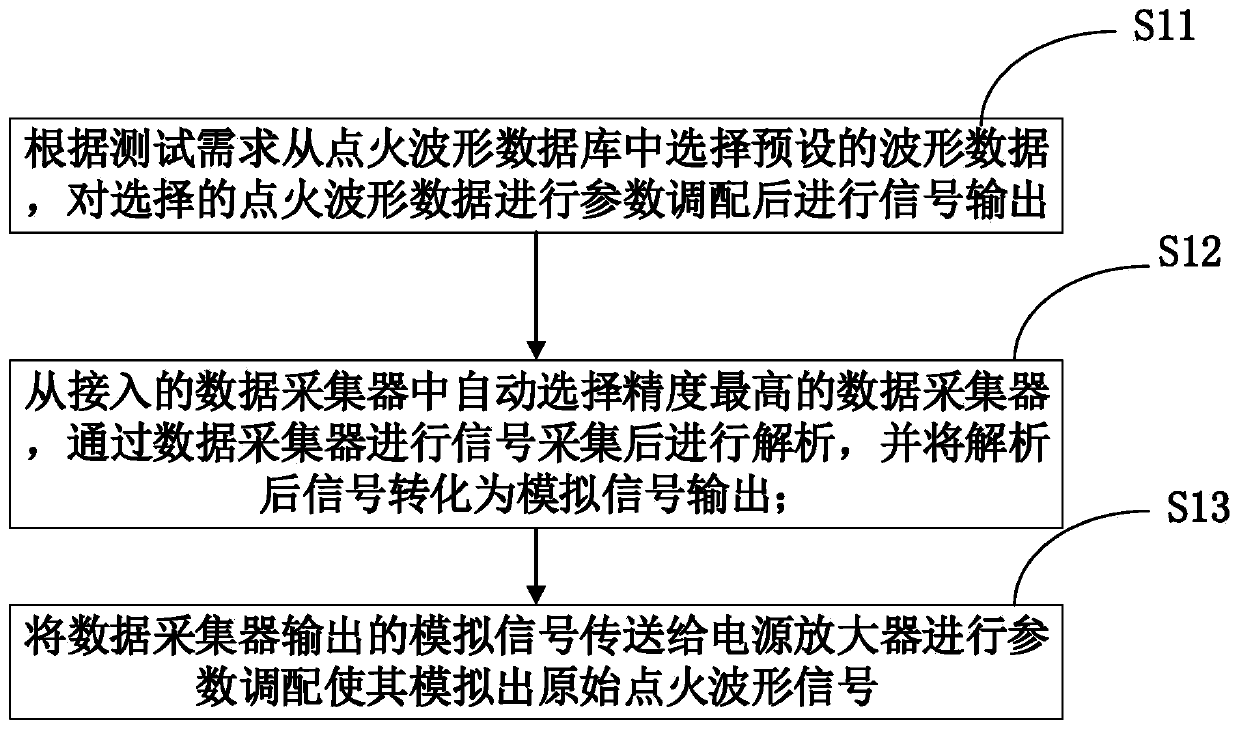

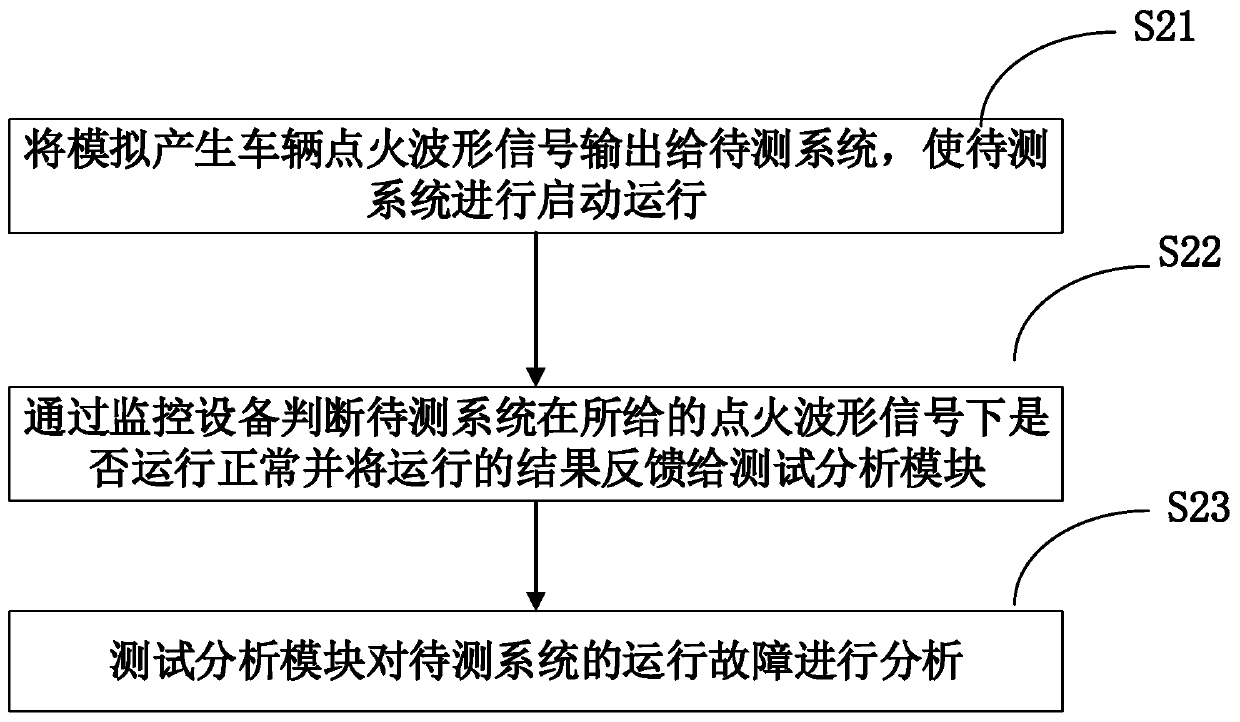

[0070] This implementation provides a simulated ignition test method for a vehicle, including a method for forming a simulated vehicle ignition waveform and a method for testing a system to be tested by using the simulated vehicle ignition waveform. The method for forming a simulated vehicle ignition waveform includes the following steps:

[0071]Step S11, selecting preset waveform data from the ignition waveform database according to the test requirements, performing parameter adjustment on the selected ignition waveform data, and then outputting signals;

[0072] Specifically, the ignition waveform database is stored in the host computer, and the parameter adjustment of the ignition waveform data is performed through the waveform adjustment module in the host computer;

[0073] The ignition waveform database is configured to store the ignition waveform data generated by vehicle pressure ignition. The ignition waveform data includes parameters such as output accuracy and vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com