Alarm height-adjustable liquid level sensor assembly with liquid storage tank cover

A liquid level sensor, adjustable technology, applied in the direction of caps with auxiliary devices, containers, container decorations, etc., can solve the problems that cannot be adjusted arbitrarily, the process is difficult to control, and the liquid storage tank has no alarm, so as to reduce the development cost and cycle, and the effect of improving production and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

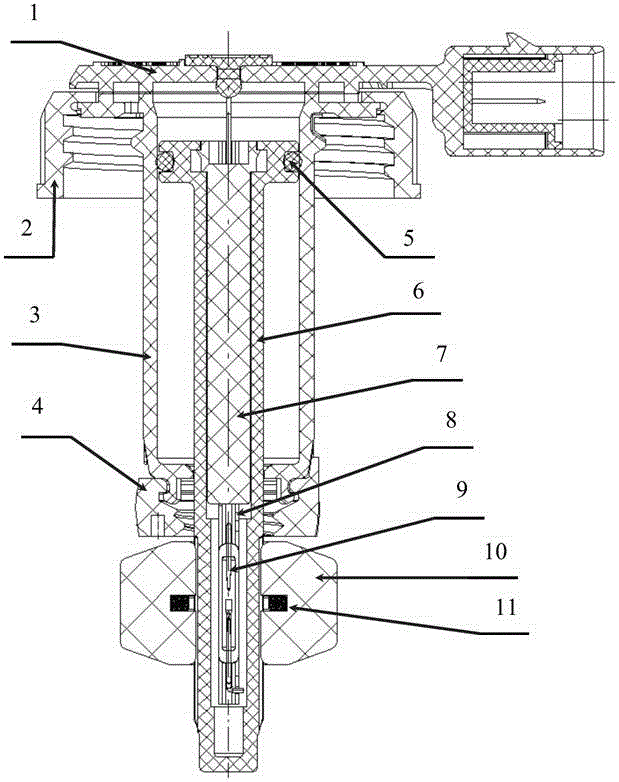

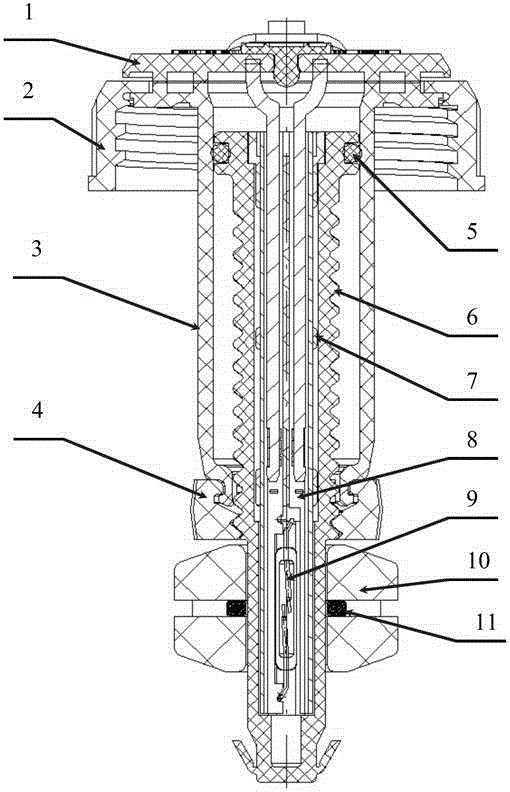

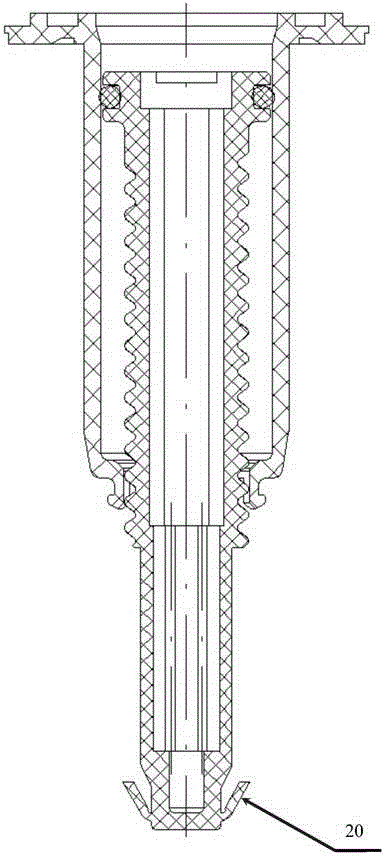

[0042] Such as Figure 1-4 As shown, the present invention includes a dust-proof ventilation cap 1, a screw cap 2, a sleeve 3, a push rod 6 and a conductive metal strip 12, and the screw cap 2 is set outside the upper end of the sleeve 3, and the screw cap 2 can rotate freely, preventing The dust ventilation cover 1 is welded 21 on the upper end face of the sleeve 3 by ultrasonic welding, such as Figure 10 As shown, the dust-proof ventilation cover 1 and the end face of the sleeve 3 are sealed. Such as Figure 5 As shown, the center of the bottom surface of the dust-proof ventilation cover 1 is fixed with two conductive metal strips 12 extending downward in parallel, and the conductive metal strips 12 are as follows: Figure 17 As shown, the upper end of the conductive metal strip 12 is connected to the wire harness interface 16 on the side of the dust-proof ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com