Connecting piece inner insertion type steel pipe column and steel beam connection joint

A technology for connecting nodes and connectors, applied in the direction of buildings and building structures, can solve the problems of complex welding seam intersection, affecting the beauty of buildings, damage to the mechanical performance of nodes, etc., to achieve superior bending performance, simple force transmission mechanism, The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

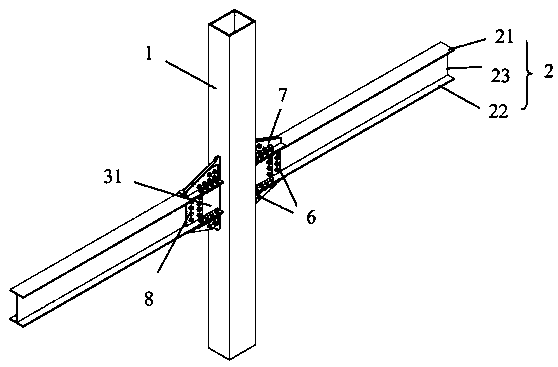

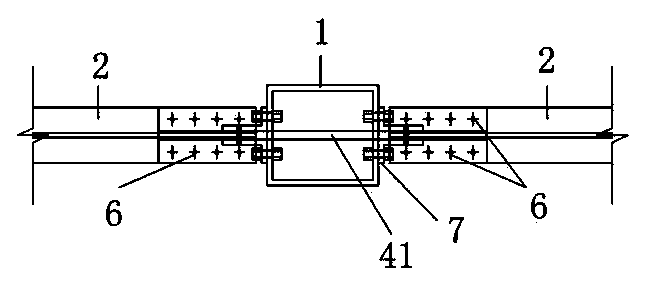

[0040] Such as figure 1 , figure 2 As shown, the connection node of the internally inserted steel pipe column and the steel beam includes a steel pipe column 1, a steel beam 2 and a connecting piece. The connecting piece is arranged vertically, and the connecting piece horizontally penetrates the steel pipe column 1 and protrudes from the side wall of the steel pipe column 1. The connecting piece is welded to the flange of the steel pipe column 1, that is, the connecting piece is welded at the junction of the steel pipe column 1. The steel beam 2 is arranged on one side of the connecting piece, the web 23 of the steel beam 2 is arranged vertically, and the flanges of the steel beam 2 are respectively connected with The upper part and the lower part of the piece are connected by high-strength bolts 6, and the web 23 of the steel beam 2 is connected with the high-strength bolt 6 in the middle of the connecting piece.

[0041] Specifically, the steel pipe column 1 is horizontally pr...

Embodiment 2

[0058] The structure of this example is roughly the same as that of Example 1, but the differences are:

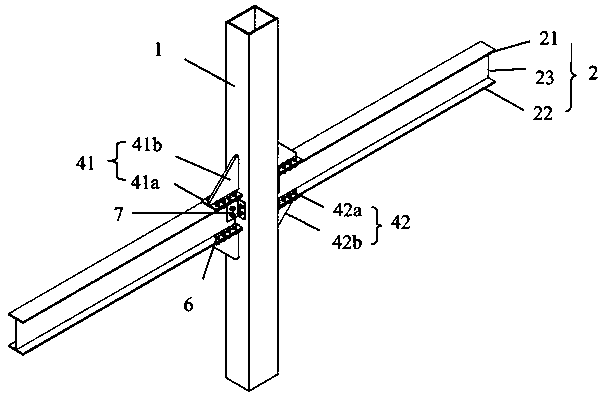

[0059] Such as image 3 , Figure 4 As shown, the cross section of the steel tube column 1 is rectangular or square, and the form is a hollow steel tube column 1 or a concrete-filled steel tube concrete composite column. The web 23 of the steel beam 2 and the side wall of the steel pipe column 1 are connected by an angle steel 7.

[0060] The connector includes an upper inner insert 41 and a lower inner insert 42, the upper inner insert 41 is located above the lower inner insert 42, and the upper inner insert 41 includes an upper flange connecting plate 41a and an upper vertical plate 41b that are perpendicular to each other. The lower end of the upper vertical plate 41b is connected to The middle of the upper flange connecting plate 41a is fixed; the lower inner insert 42 includes a lower flange connecting plate 42a and a lower vertical plate 42b that are perpendicular to each...

Embodiment 3

[0074] The structure of this example is roughly the same as that of Example 2, but the differences are:

[0075] Such as Figure 5 , Image 6 As shown, the connecting piece includes an upper connecting piece and a lower connecting piece. The upper connecting piece and the lower connecting piece respectively penetrate the steel pipe column 1 horizontally and protrude from the side wall of the steel pipe column 1, and the upper connecting piece is provided with an upper groove horizontally passing through the upper connecting piece. The lower connecting piece is provided with a lower groove that horizontally penetrates the lower connecting piece. The extension direction of the upper groove and the lower groove is parallel to the axial direction of the steel beam 2, that is, the extension of the upper groove and the lower groove The direction is parallel to the length of the steel beam 2. The flange of the steel beam 2 includes an upper flange 21 and a lower flange 22. The upper groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com