Construction method of ballastless track in heavy haul railway tunnel group

A ballastless track and construction method technology, applied in tracks, track laying, track maintenance, etc., can solve the problem of not meeting the high-precision and high-efficiency requirements of heavy-duty railways, and achieves alleviation of the contradiction between operation and maintenance. The effect of the accurate laying position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

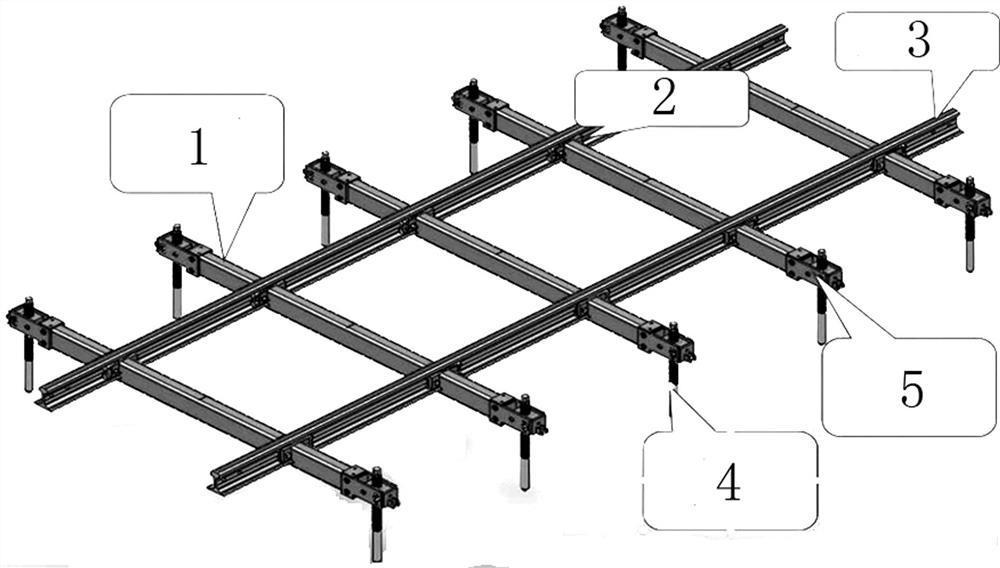

Image

Examples

Embodiment

[0353] 1. Project overview

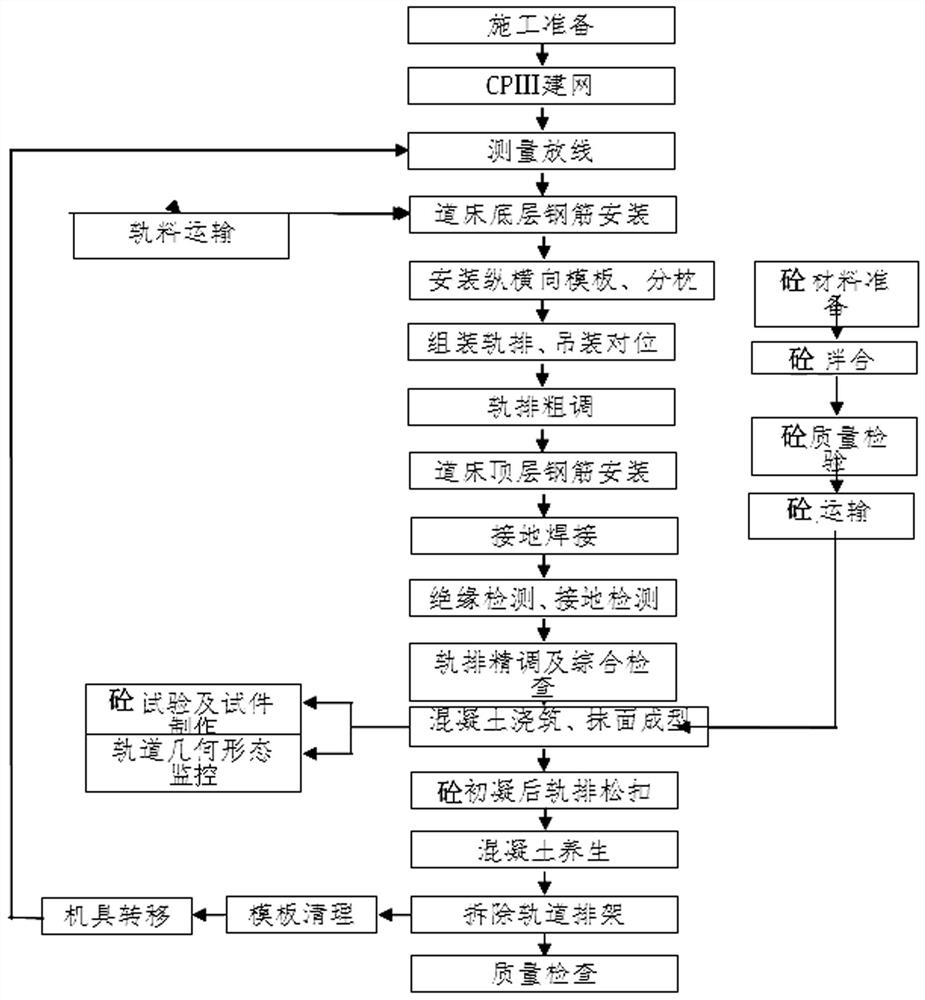

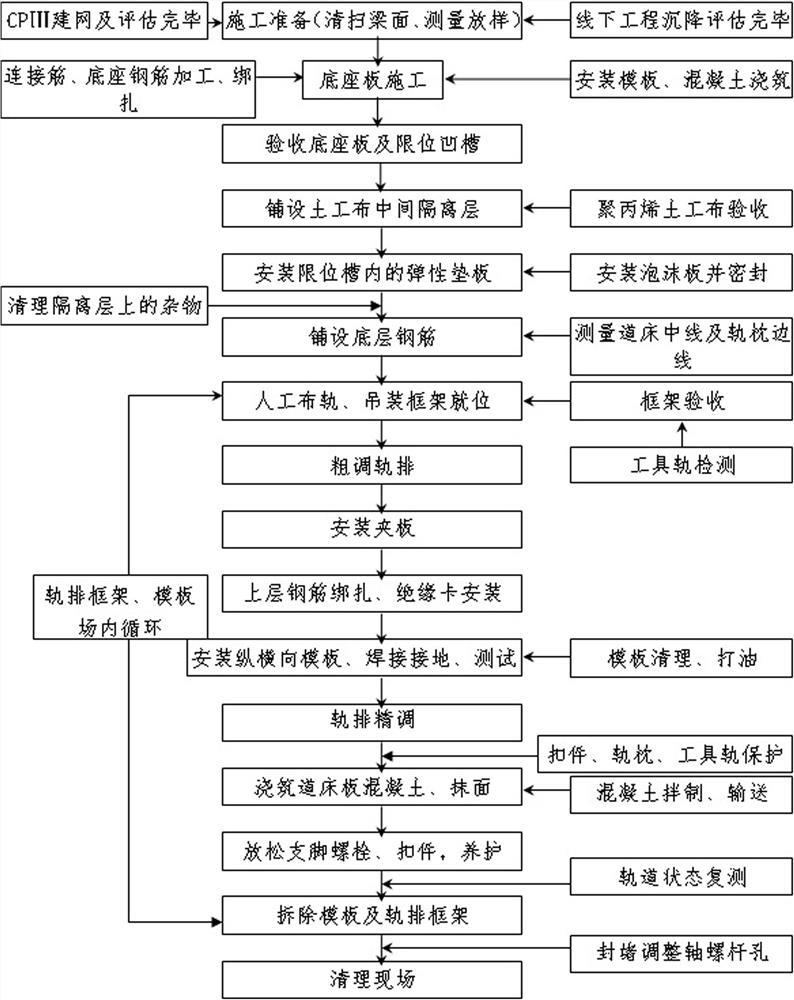

[0354] The starting and ending mileage of MHTJ-17 bidding section of the new Mengxi-Central China railway coal transportation channel civil engineering project: DK828+253.5~DK883+289.5, of which the main line of the whole line is 55.036 kilometers long, and the uplink and downlink lines are 2.2 kilometers. There are 26 tunnels in this tender section, with a total length of 16804.3 meters, accounting for 30.5% of the total length of the line. In principle, ballastless tracks are laid on tunnels with a length of 1 km or more, and elastic bearing block type ballastless tracks are generally laid in the tunnels; when ballastless tracks in tunnel group sections are considered to be laid in sections, heavy-duty Cushion buried ballastless track. The total length of the ballastless track (single track) is 24.157km.

[0355] 2. Application

[0356] The MHTJ-17 bid section of the new Mengxi-Central China railway coal transportation channel civil engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com