Paint continuous and quantitative charging, mixing and blanking production process

A production process and material mixing technology, applied in the field of material transmission, can solve the problems of complex transfer process, low work efficiency, troublesome quantitative feeding, etc., and achieve the effect of unified power unit, high production efficiency and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

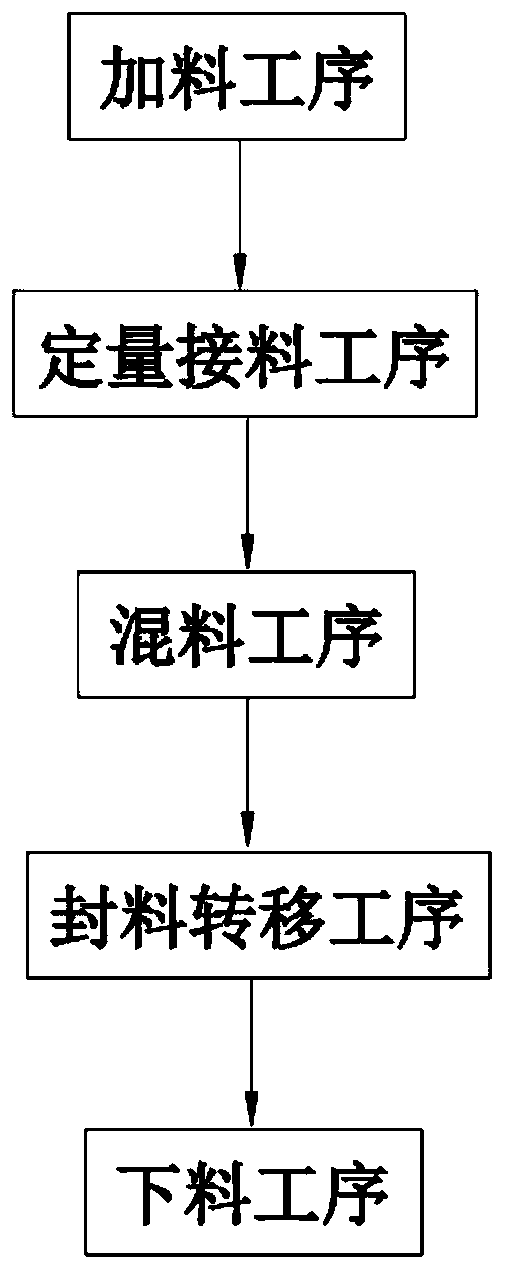

[0048] Such as Figure 1-2 As shown, a continuous quantitative feeding and mixing and blanking production process for coatings includes:

[0049] Step 1, feeding process: several feeding devices arranged sequentially along the conveying direction are loaded with different materials, the opening and closing assembly seals the opening at the bottom of the feeding device, the storage area above the feeding device is opened, and the materials fall into the In the quantitative feeding area below it;

[0050] Step 2, Quantitative material receiving process: When the material receiving device is sequentially transported to the bottom of each feeding device by the conveying device, the storage area is blocked by the mutual conflict with the opening and closing components, and the material stops falling into the quantitative feeding area, and at the same time The bottom opening of the feeding device is opened, and the material in the quantitative feeding area falls into the material r...

Embodiment 2

[0063] For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 is described below; the difference between Embodiment 2 and Embodiment 1 is:

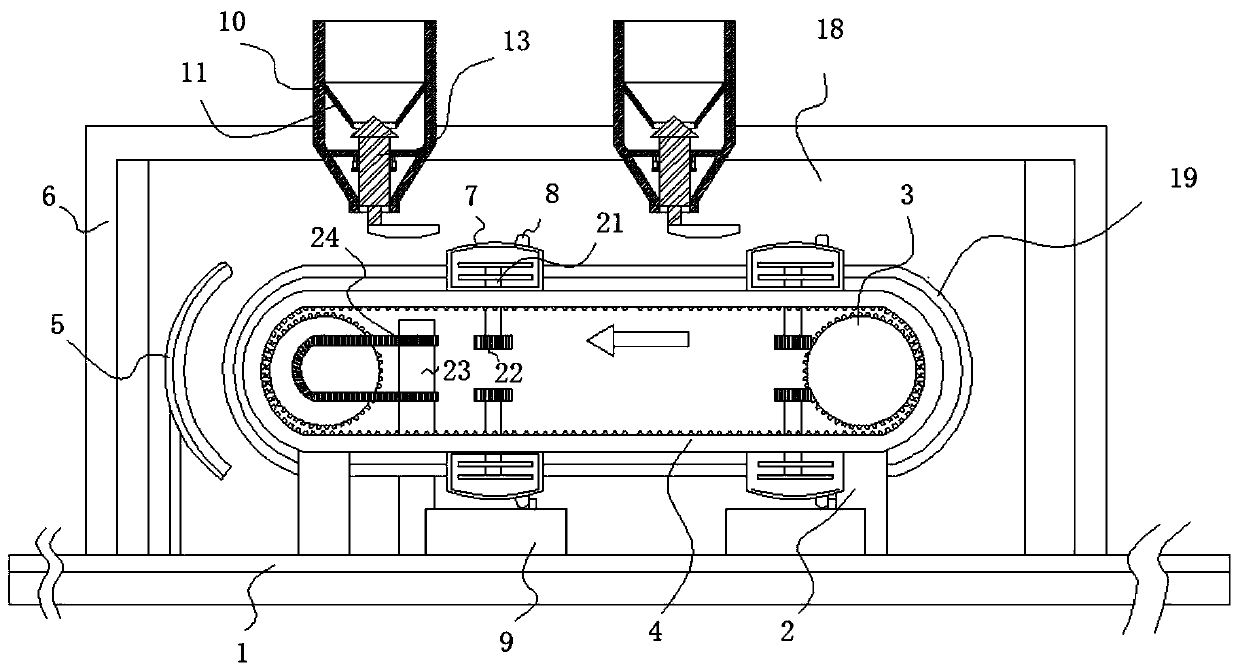

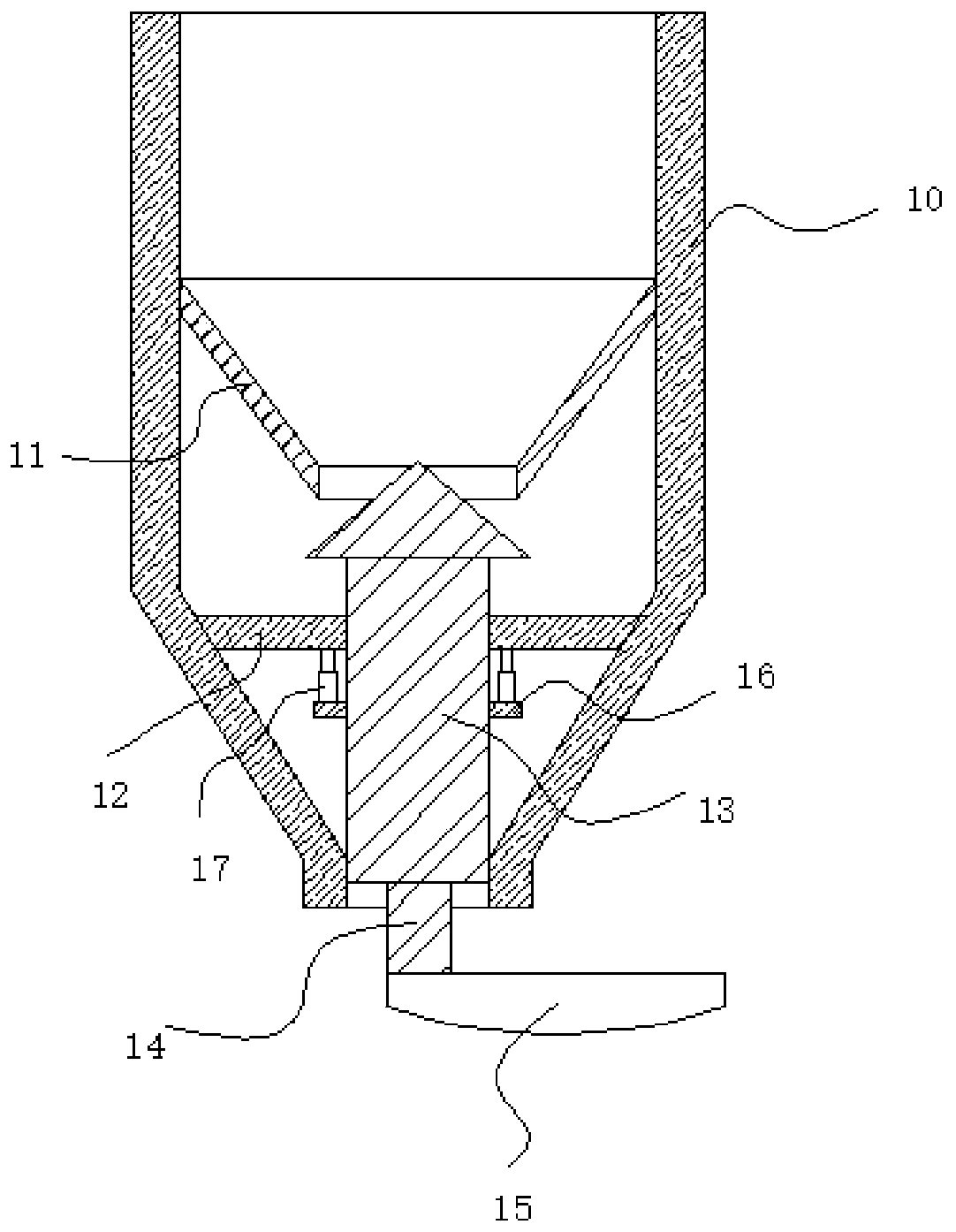

[0064] Such as Figure 2-7 , a continuous quantitative feeding and mixing and unloading device, including a transmission belt 1, a conveying device is arranged above the transmission belt 1, a material receiving device is fixed on the conveying device, and a stirring device is provided inside the material receiving device, and a conveying device is provided There is a linkage device that interacts with the stirring device. A fixed frame 6 fixed on the ground is provided above the transmission belt 1. A positioning device is fixed on the inner wall of the fixed frame 6, and on the positioning device that the receiving device slides, the fixed frame 6 There are two unloading devices fixed above the conveying device, and the unloading device interacts with the receiving device on the conveying device. One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com