Motor cooling and vibration reducing mechanism

A shock-absorbing mechanism and heat-dissipating shell technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor heat dissipation, low refrigerant fluidity, motor damage, etc., to improve the heat exchange rate and speed up the heat exchange. Efficiency, the effect of increasing the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

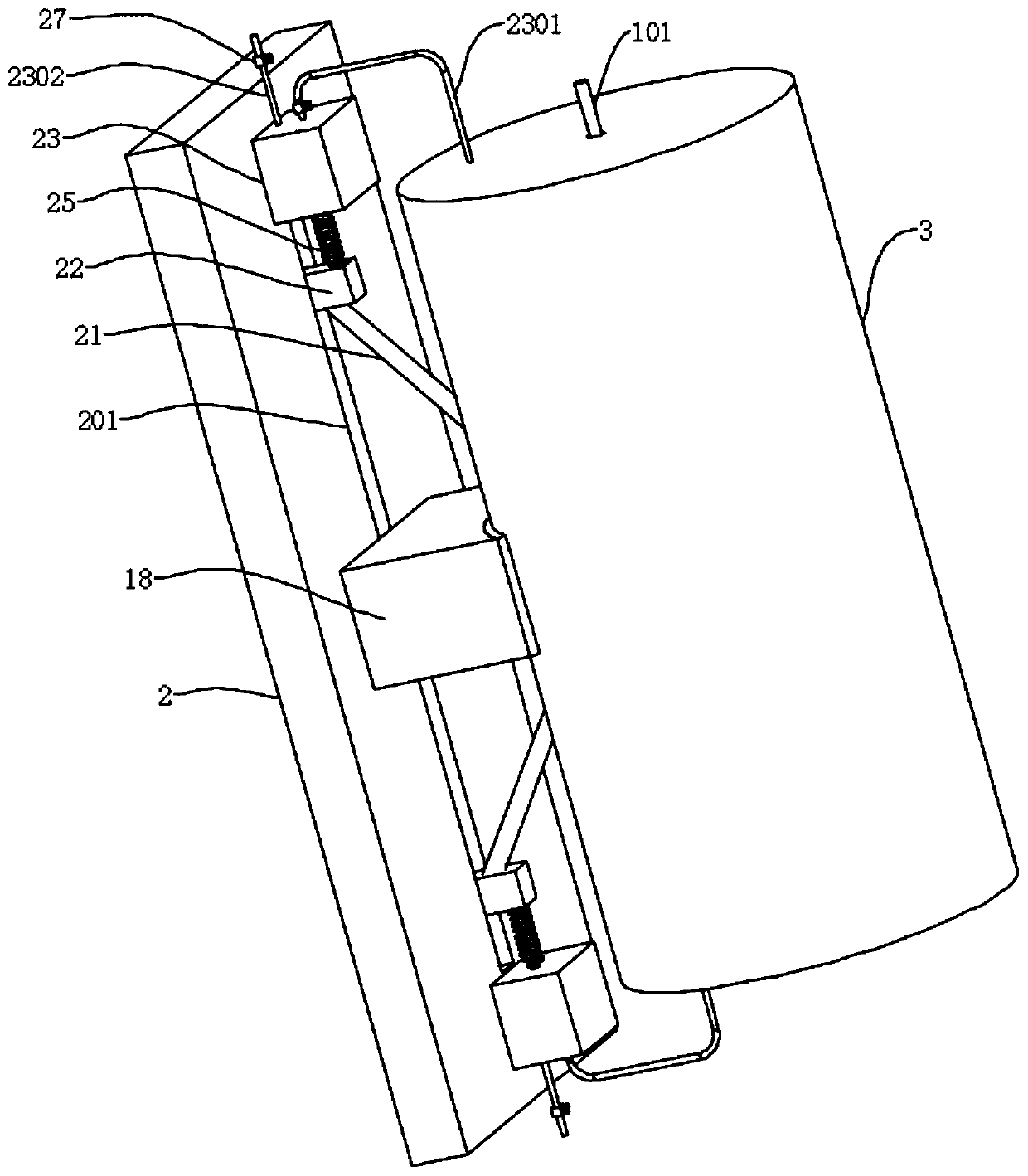

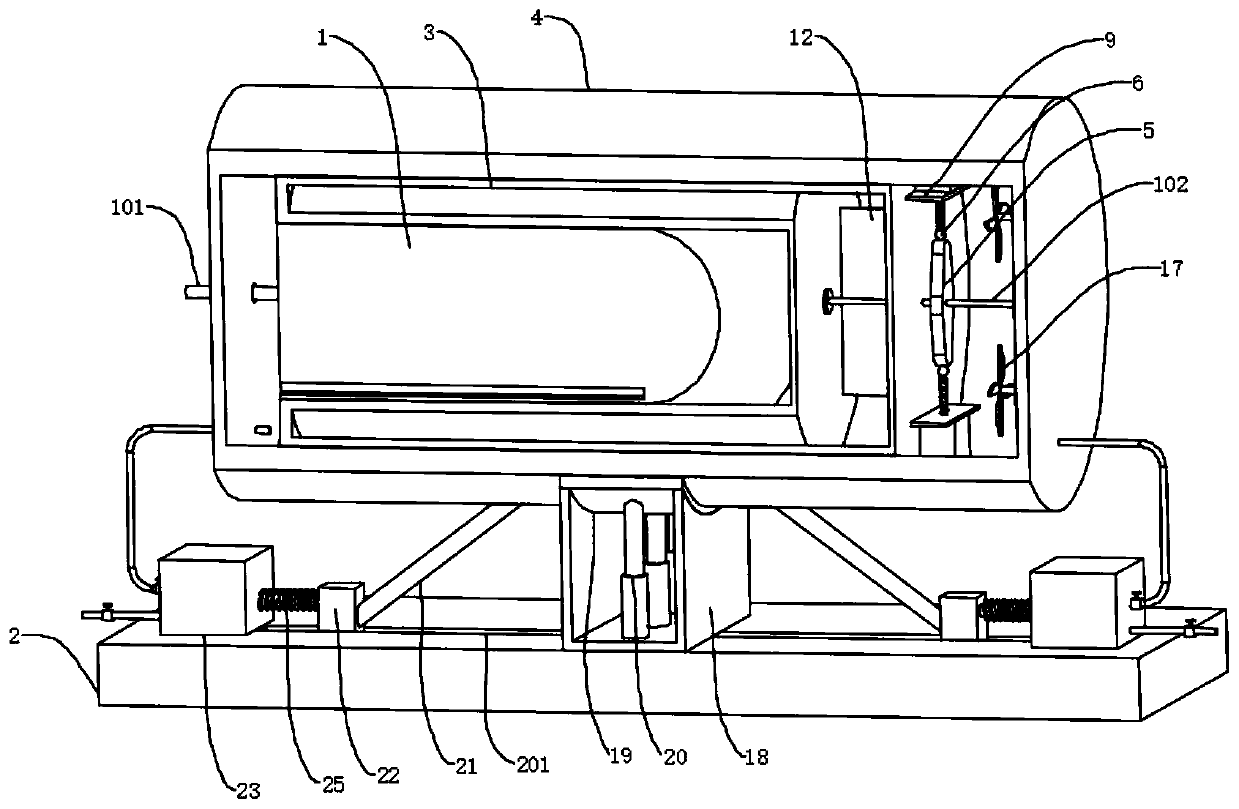

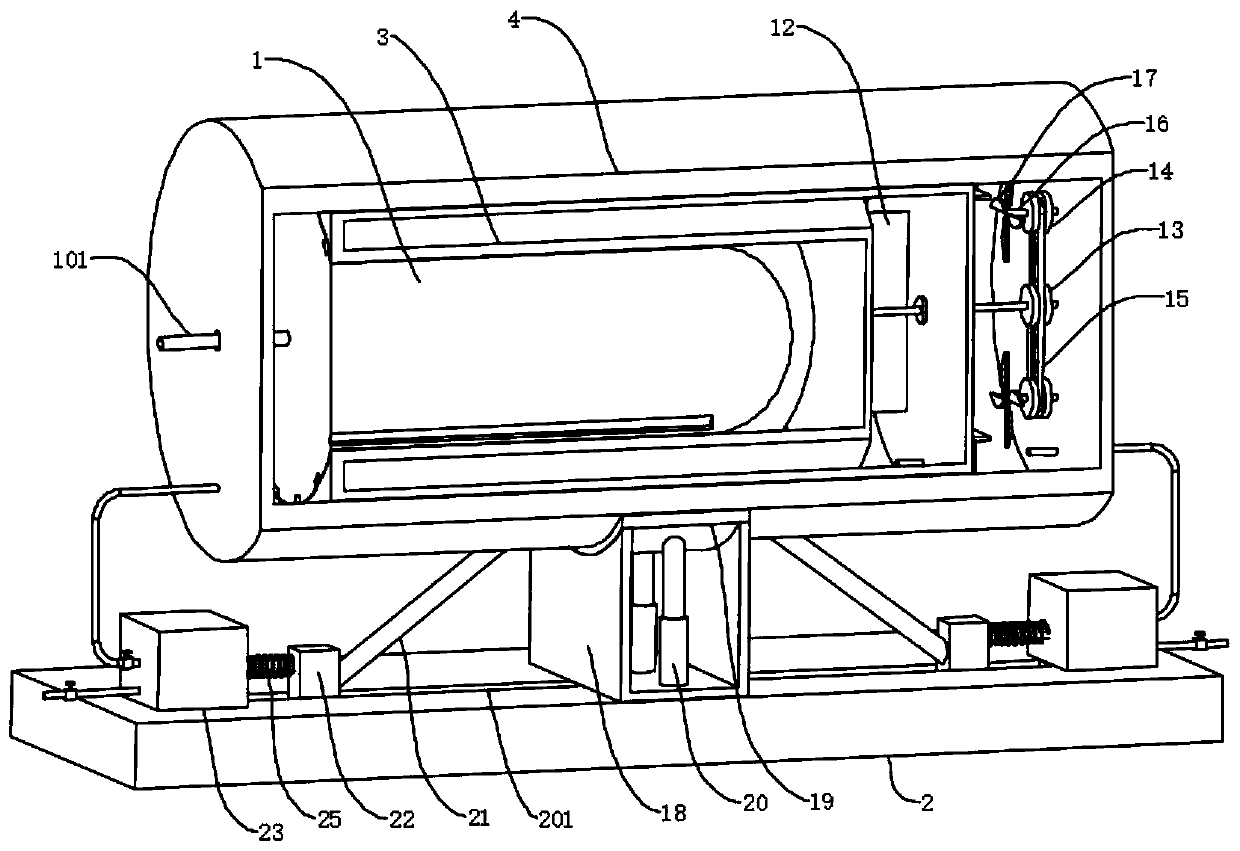

[0032] refer to Figure 1-3, a motor cooling and shock absorbing mechanism, comprising a motor body 1, a heat dissipation shell 4 and a base 2, the outer wall of the motor body 1 is fixedly connected with a heat dissipation water jacket 3, and the motor body 1 is fixedly connected to the inside of the heat dissipation casing 4 through the heat dissipation water jacket 3, The two ends of the motor body 1 are respectively fixedly connected with a first drive shaft 101 and a second drive shaft 102, one end of the first drive shaft 101 extends outward through the side wall of the heat dissipation shell 4, and one end of the second drive shaft 102 passes through the cooling water The side wall of the sleeve 3 extends to the inside of the heat dissipation shell 4, and the heat dissipation water jacket 3 is fixedly connected with a symmetrically arranged support plate 9 on the side wall inside the heat dissipation shell 4, and the side wall of the support plate 9 is fixedly connected ...

Embodiment 2

[0036] refer to Figure 4 , a motor cooling and damping mechanism, which is basically the same as Embodiment 1, the difference is that the refrigerant pumping assembly includes a liquid tank 10, and the side wall of the liquid tank 10 is slidably connected with a first slide bar 7, and the first slide bar 7 One end placed inside the liquid tank 10 is fixedly connected with a first piston plate 11, a water pipe 1001 is plugged into the side wall of the liquid tank 10, and one end of the water pipe 1001 passes through the side wall of the heat dissipation water jacket 3 and extends to the inside of the heat dissipation water jacket 3;

[0037] The reciprocating mechanism includes a two-way cam 5 and a rolling ball 6. The two-way cam 5 is connected to the second drive shaft 102 placed on the outer wall of the heat dissipation shell 4. The rolling ball 6 is fixedly connected to the end of the first slide bar 7 away from the liquid tank 10. The two-way cam 5 is offset against the r...

Embodiment 3

[0040] refer to Figure 2-3 , a motor cooling and shock absorbing mechanism, which is basically the same as Embodiment 2, the difference is that the heat dissipation assembly includes fan blades 17, and the fan blades 17 are movably connected to the inner wall of the heat dissipation housing 4 through the rotating rod 16, and the second drive shaft 102 A first pulley 13 is socketed on the outer wall, a second pulley 14 is socketed on the outer wall of the rotating rod 16, and the first pulley 13 and the second pulley 14 are connected by a belt 15 through transmission;

[0041] The rotation of the second drive shaft 102 will drive the first pulley 13 connected to it to rotate, and the first pulley 13 will drive the second pulley 14 to rotate through the belt 15, and the second pulley 14 will drive the rotating rod 16 to rotate to drive the fan. The leaves 17 rotate to dissipate heat inside the heat dissipation housing 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com