A preparation method of polyimide composite material and application of polyimide composite material in battery

A technology of polyimide and composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrical conductivity and poor electrochemical performance of batteries, and achieve high cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] The preparation of embodiment 1 polyimide composite material

[0110]Step A: add superconducting carbon black (Super P) of polyimide synthesis amount 5% in small beaker, then add the sodium carboxymethyl cellulose (CMC) of superconducting carbon black (Super P) content 1.5%, Add 20mL solvent N,N-dimethylformamide (DMF) and magnetically stir for 10min, then transfer to an ultrasonic wave for ultrasonic dispersion for 30min.

[0111] Step B: Add 1,4,5,8-naphthalene tetracarboxylic anhydride powder and ethylenediamine solution in the N,N-dimethylformamide (DMF) solution at a molar ratio of 1:1, keep magnetic stirring, and then Add the mixture from step A. It was carried out in a glass flask protected by an argon atmosphere. The flask was transferred to a 50°C oil bath, and the temperature was gradually raised to 150°C, and the reaction was carried out at this temperature for 4h.

[0112] Step C: Collect the product, centrifuge, and remove the supernatant. For the centr...

Embodiment 2

[0114] The preparation of embodiment 2 polyimide composite material

[0115] The specific operation is the same as in Example 1, the difference is that step A is: add superconducting carbon black (Super P) with a polyimide synthesis amount of 10% in a small beaker, and the obtained polyimide composite material is designated as sample 2.

Embodiment 3

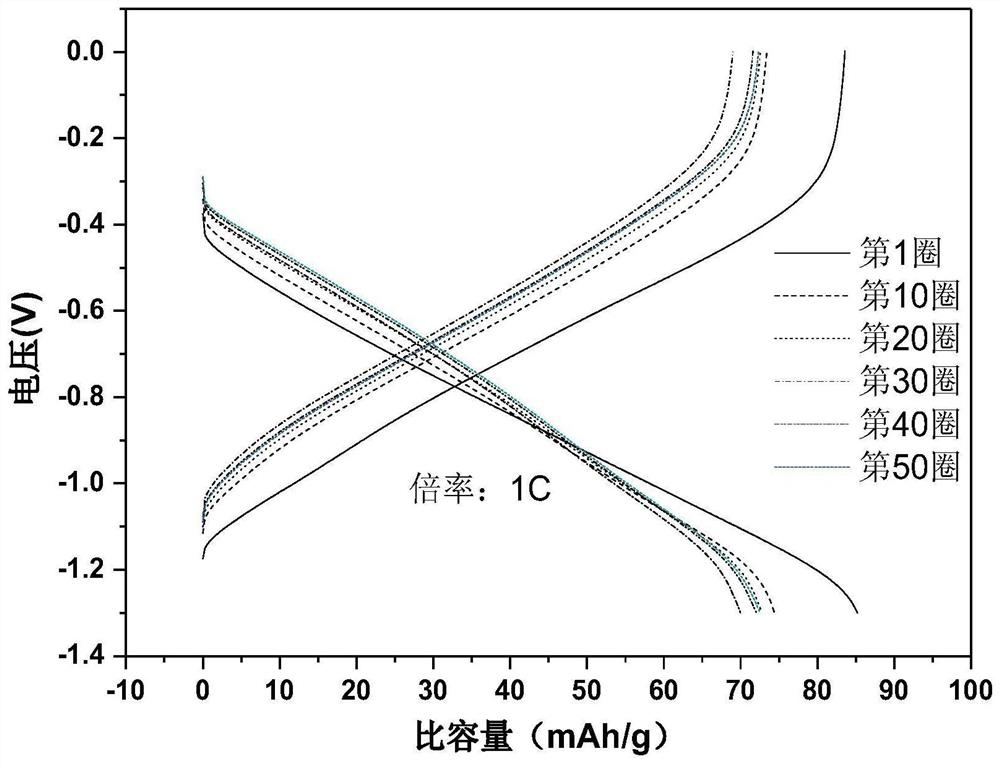

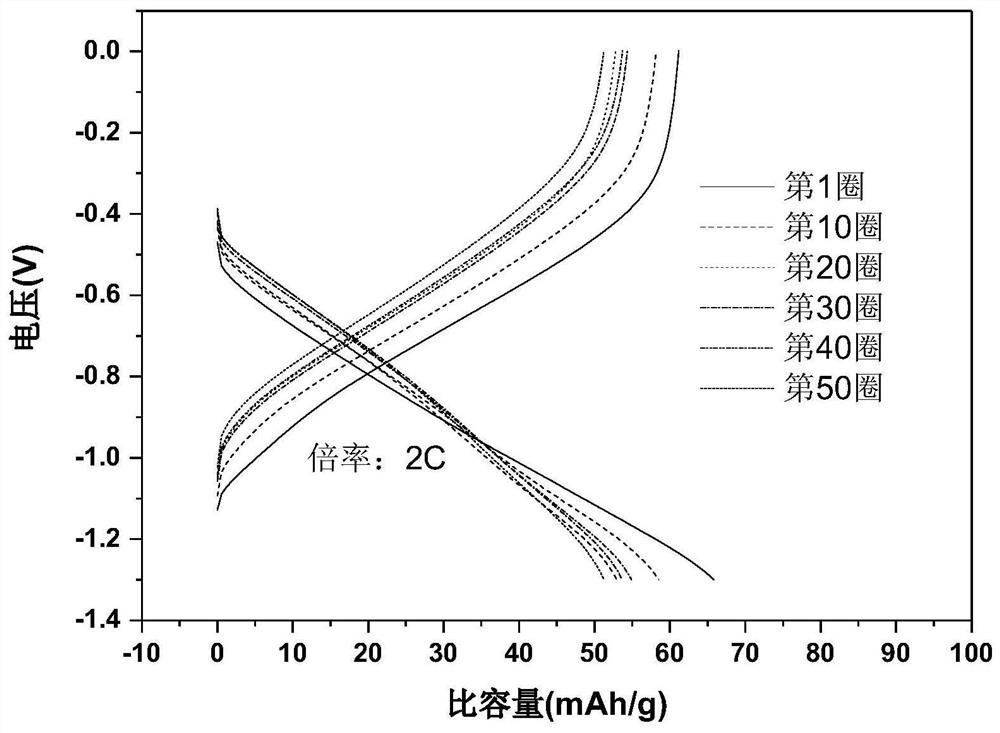

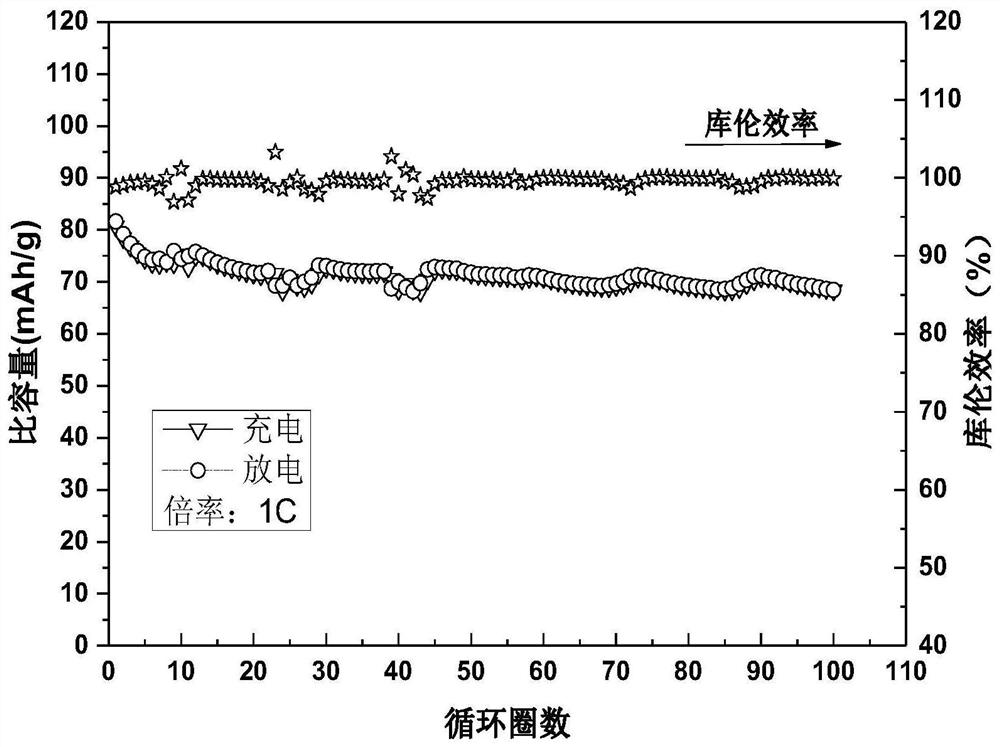

[0118] The preparation of embodiment 3 half cell

[0119] half cell

[0120] Electrolyte: 2.0M lithium sulfate (Li 2 SO 4 ) aqueous solution

[0121] Diaphragm: glass fiber filter paper (porosity below 1 micron, thickness about 260 microns)

[0122] Positive electrode: polyimide-based carbon-based composite electrode

[0123] Negative electrode: activated carbon cloth

[0124] Preparation process: negative electrode case / negative electrode / diaphragm / positive electrode / gasket / shrapnel / positive electrode case. After assembly, use a button battery sealing machine to seal under a pressure of 1500Kg. .

[0125] Half-cell 1-1, half-cell 1-2, and half-cell 1-D1 were obtained by using sample 1 in Example 1, sample 2 in Example 2, and sample D1 in Comparative Example 1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com