Turbine disc multi-failure-mode reliability optimization method based on EGRA

A failure mode and optimization method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as waste of calculations, failure to consider the impact of correlation relationships, etc., to reduce distribution, reduce times, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

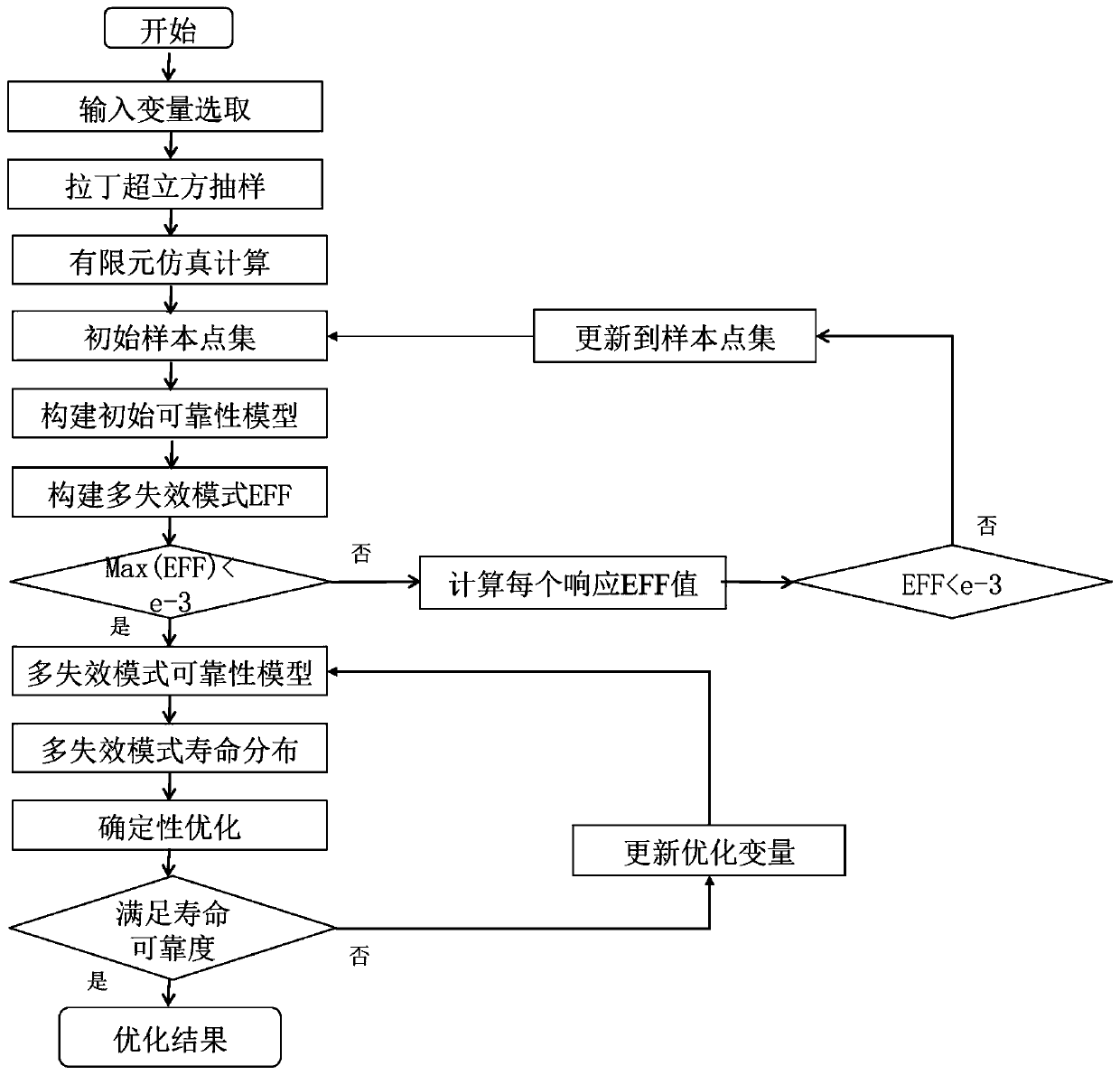

[0020] The technical solution of the EGRA-based multi-failure mode reliability optimization method for a turbine disk of the present invention will be further described below with reference to the accompanying drawings.

[0021] (1) For the existing turbine disk, select a sector model with a tongue and groove for full parametric modeling, group the geometric parameters of the turbine disk, integrate DOE Latin hypercube sampling, UG update model, ANSYS extraction maximum, etc. Sensitivity analysis of parameters is carried out to select the angle along the lower side of the web on the right side of the disk, the thickness of the disk center on the right side, the width of the journal on the right side of the disk, the axial coordinates of the positioning point of the right web, and the radial direction of the positioning point of the left web. The coordinates of the five disk body geometry and the five geometric parameters that have the greatest influence on the maximum equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com