Intelligent defect detection system for paper bottle production and application equipment thereof

A technology of intelligent detection and application equipment, which is applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, which can solve the waste of production costs, time-consuming and laborious manual sampling inspection, and the time of manual inspection cannot be extended for a long time, etc. problems, to achieve the effect of ensuring production flexibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

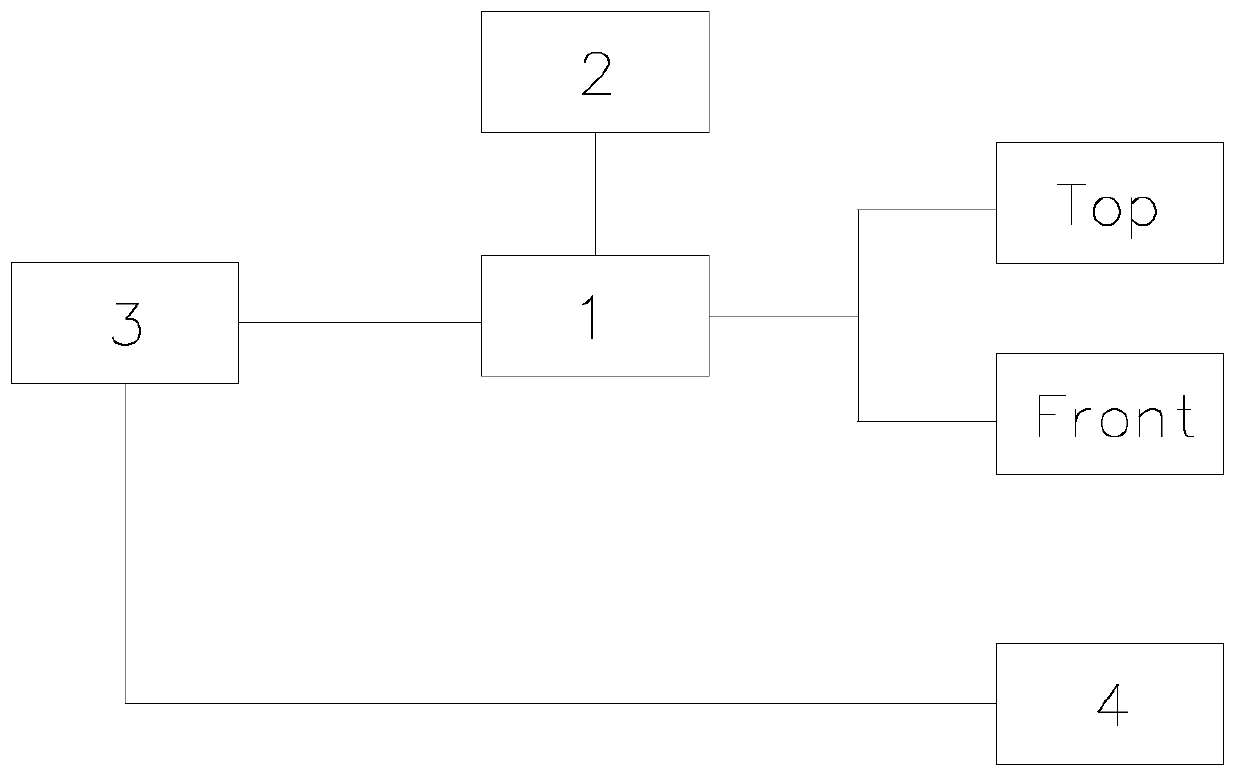

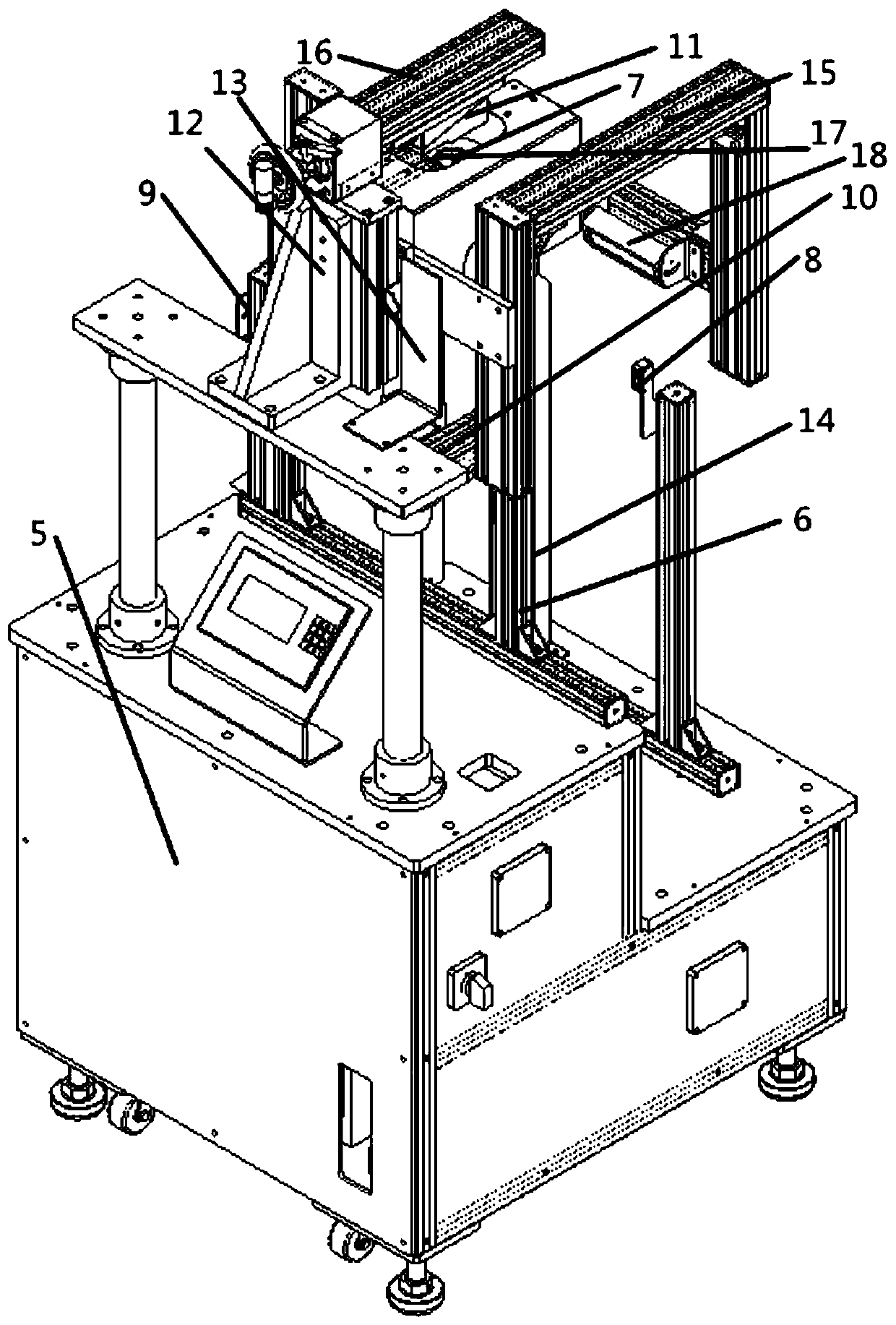

[0017] As shown in the figure, an intelligent defect detection system for paper bottle production and its application equipment, the detection system includes a double-station detection module 1, a product sensing module 2, a comparative analysis module 3 and a synchronous blow-off module 4; The double station detection module 1 includes a Top module and a Front module, the Top module collects the top photo of the product, the Front module collects the front photo of the product, and the photos of the two angles of the product transported at high speed are taken and collected by the equipment; The product sensing module 2 described above is used to sense the position of the product and is connected to the equipment for detection; the comparative analysis module 3 compares the collected product photos with the standard sample photos to analyze whether the product deviation exceeds the standard; the described synchronous blowing In addition to module 4, the results obtained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com