Nano photo-catalytic purification fabric and manufacturing method thereof

A manufacturing method and nano-light technology, applied in rayon manufacturing, biochemical fiber treatment, fiber chemical characteristics, etc., can solve the problems that consumers cannot meet the pursuit of comfort, green, environmental protection, health care, and no formaldehyde removal, and avoid mold. and corruption, high economic and social benefits, and high killing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

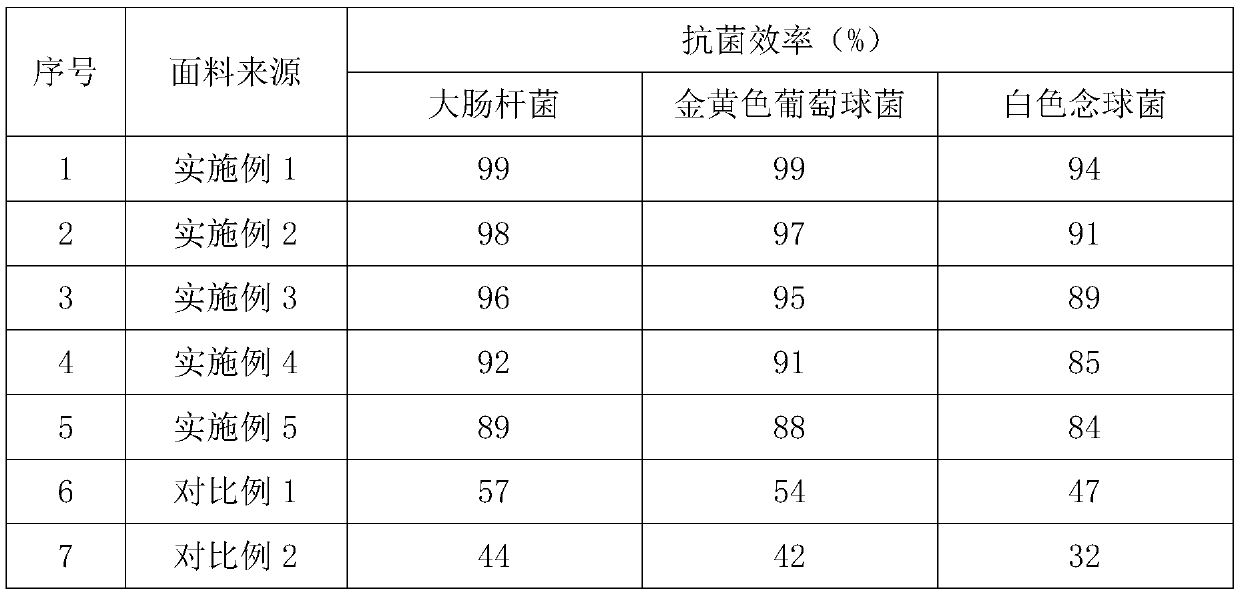

Examples

Embodiment 1

[0052] The manufacturing method of the nano-light purification fabric provided in this embodiment comprises the following steps:

[0053](1) dissolving chitosan in deionized water, adding acetic acid, obtaining a chitosan solution with a mass concentration of 5% after ultrasonic dispersion, and dispersing graphene oxide in deionized water to obtain a graphene oxide with a mass concentration of 0.5% Dispersion liquid, according to the weight ratio of chitosan and graphene oxide is the ratio of 5:1, the graphene oxide dispersion liquid is added dropwise in the chitosan solution, after dropping, the mixed solution is transferred to the hydrothermal reaction kettle , put the reaction kettle into a hydrothermal box, place it in a closed environment at 140°C for hydrothermal reaction for 18 hours, and obtain a graphene-chitosan composite hydrogel after cooling, and the obtained graphene-chitosan composite hydrogel After the gel is broken, freeze-dry to obtain graphene-chitosan compo...

Embodiment 2

[0057] The manufacturing method of the nano-light purification fabric provided in this embodiment comprises the following steps:

[0058] (1) dissolving chitosan in deionized water, adding acetic acid, obtaining a chitosan solution with a mass concentration of 5% after ultrasonic dispersion, and dispersing graphene oxide in deionized water to obtain a graphene oxide with a mass concentration of 0.5% Dispersion liquid, according to the weight ratio of chitosan and graphene oxide is the ratio of 6:1, the graphene oxide dispersion liquid is added dropwise in the chitosan solution, after dropping, the mixed solution is transferred to the hydrothermal reaction kettle , put the reaction kettle into a hydrothermal box, raise the temperature to 145°C, and conduct a hydrothermal reaction for 16 hours. After cooling, the graphene-chitosan composite hydrogel was obtained, and the obtained graphene-chitosan composite hydrogel was After crushing, through freeze-drying, obtain graphene-chit...

Embodiment 3

[0062] The manufacturing method of the nano-light purification fabric provided in this embodiment comprises the following steps:

[0063] (1) dissolving chitosan in deionized water, adding acetic acid, obtaining a chitosan solution with a mass concentration of 5% after ultrasonic dispersion, and dispersing graphene oxide in deionized water to obtain a graphene oxide with a mass concentration of 0.5% Dispersion liquid, according to the weight ratio of chitosan and graphene oxide is the ratio of 4:1, the graphene oxide dispersion liquid is added dropwise in the chitosan solution, after dropping, the mixed solution is transferred to the hydrothermal reaction kettle , put the reaction kettle into a hydrothermal box, place it in a closed environment at 160°C for hydrothermal reaction for 14 hours, and obtain a graphene-chitosan composite hydrogel after cooling, and the obtained graphene-chitosan composite hydrogel After the gel is broken, freeze-dry to obtain graphene-chitosan comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com