Preparing method of antibacterial and antistatic spandex

An anti-static and spandex technology, applied in the direction of conductive/anti-static filament manufacturing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem that the conductivity of composite powder is difficult to guarantee, the aggregation of carbon materials cannot be avoided, and the spinning process cannot be performed and other issues, to achieve the effect of broad market prospects and application value, high durability, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

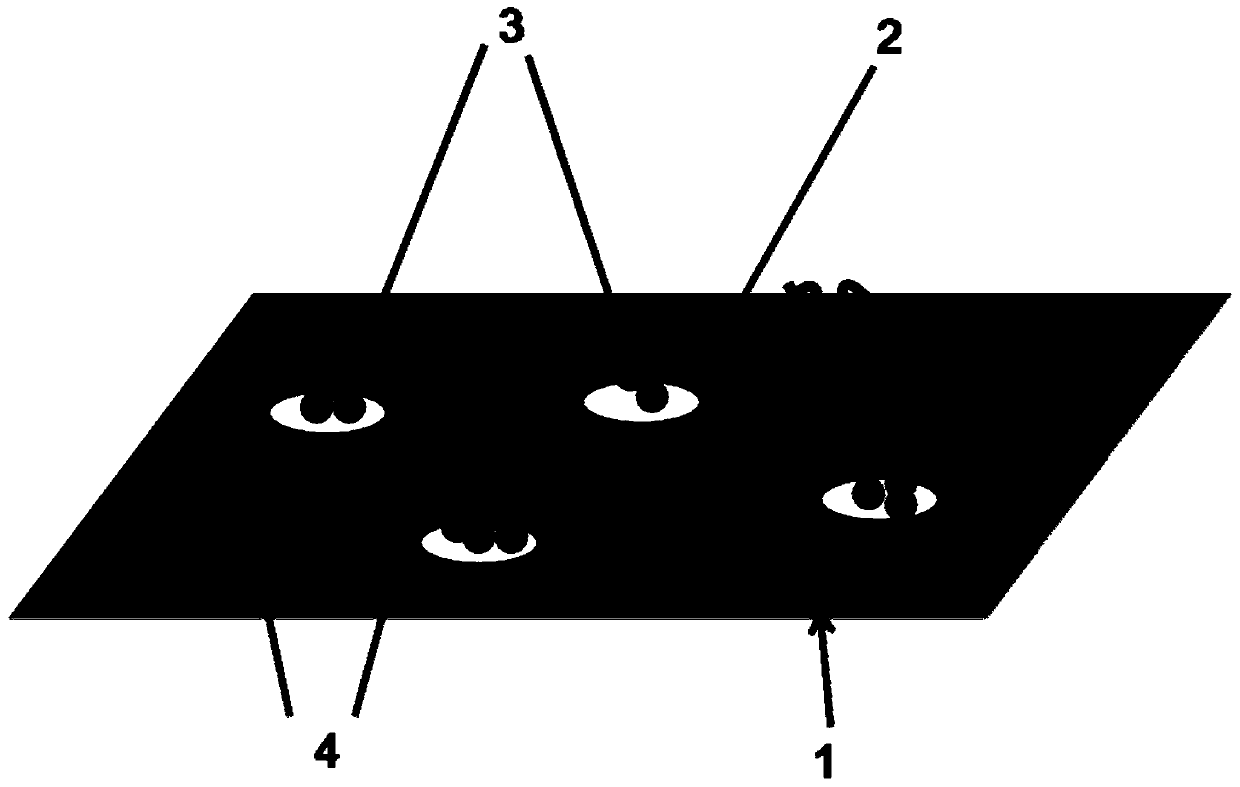

Image

Examples

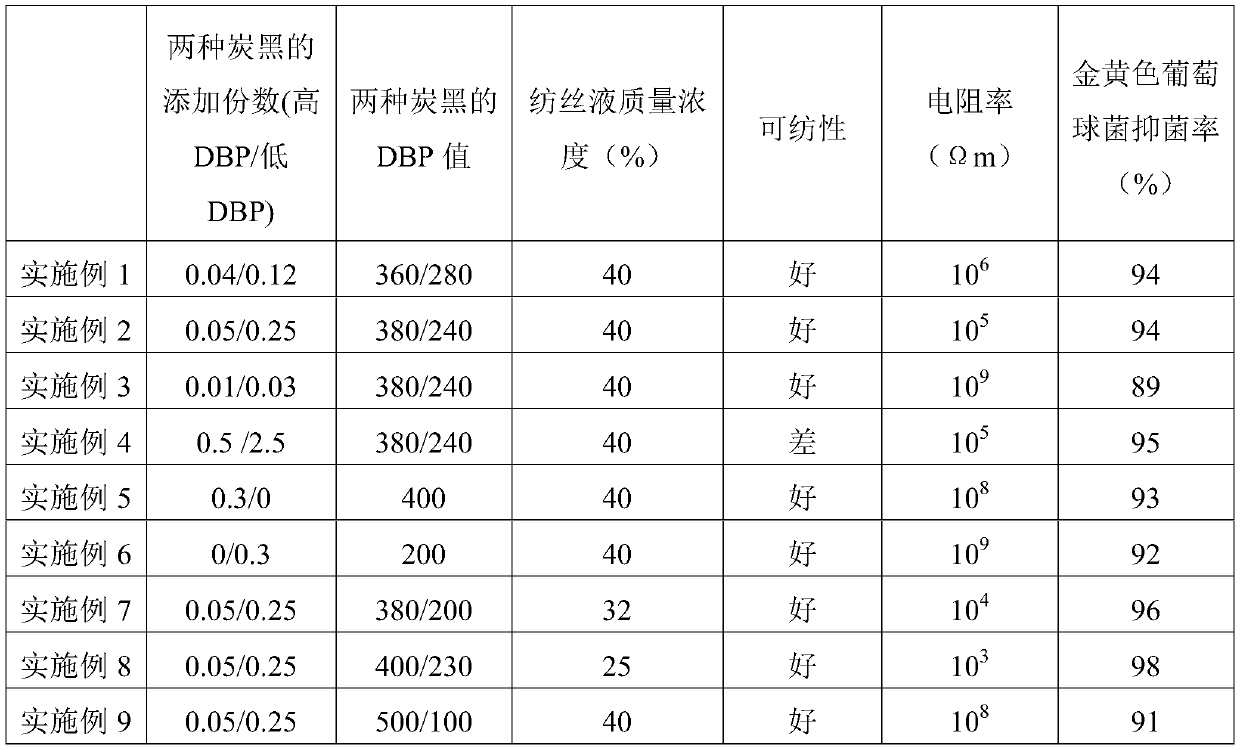

Embodiment 1

[0023] (1) Add 0.01 mass parts sodium hydroxide to 25 mass parts, mass concentration is 2mg / g graphene oxide aqueous dispersion liquid, mix and stir evenly, obtain the first mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 4;

[0024] (2) Add 0.12 parts by mass of nano-carbon black with low DBP value and 0.04 parts by mass of nano-carbon black with high DBP value to the first mixed solution obtained in step (1), stir and react at 100°C for 1h to obtain a mixed dispersion, wherein The total weight of mixed nano-carbon black is 0.16 parts by mass, the DBP value of high DBP value nano-carbon black is 360, and the DBP value of low DBP value nano-carbon black is 280;

[0025] (3) Wash the mixed dispersion obtained in step (2) until neutral, add 5 parts by mass of dimethylacetamide, heat to 70°C, and distill under reduced pressure until it is substantially anhydrous to obtain a second mixed solution;

[0026] (4) Mix the second mixed solution obtained in step (3)...

Embodiment 2

[0029] (1) Add 0.01 mass parts sodium hydroxide to 25 mass parts, mass concentration is 2mg / g graphene oxide aqueous dispersion liquid, mix and stir evenly, obtain the first mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 4;

[0030] (2) Add 0.25 parts by mass of nano-carbon black with low DBP value and 0.05 parts by mass of nano-carbon black with high DBP value to the first mixed solution obtained in step (1), stir and react at 100°C for 1h to obtain a mixed dispersion, wherein The total weight of mixed nano carbon black is 0.3 parts by mass, the DBP value of high DBP value nano carbon black is 380, and the DBP value of low DBP value nano carbon black is 240;

[0031] (3) Wash the mixed dispersion obtained in step (2) until neutral, add 5 parts by mass of dimethylacetamide, heat to 70°C, and distill under reduced pressure until it is substantially anhydrous to obtain a second mixed solution;

[0032] (4) Mix the second mixed solution obtained in step (3) ...

Embodiment 3

[0035] (1) Add 0.01 mass parts sodium hydroxide to 25 mass parts, mass concentration is 2mg / g graphene oxide aqueous dispersion liquid, mix and stir evenly, obtain the first mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 7;

[0036](2) Add 0.01 mass part of nano-carbon black with low DBP value and 0.03 mass part of high DBP value nano-carbon black to the first mixed solution obtained in step (1), stir and react at 100°C for 1h to obtain a mixed dispersion, wherein The mixed nano-carbon black gross weight is 0.04 parts by mass, the DBP value of high DBP value nano-carbon black is 380, and the DBP value of low DBP value nano-carbon black is 240;

[0037] (3) Wash the mixed dispersion obtained in step (2) until neutral, add 5 parts by mass of dimethylacetamide, heat to 70°C, and distill under reduced pressure until it is substantially anhydrous to obtain a second mixed solution;

[0038] (4) Mix the second mixed solution obtained in step (3) with the spandex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com