Steel ball heat treatment furnace

A technology for heat treatment furnaces and steel balls, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of heat treatment furnace temperature reduction, affecting the quenching and tempering effect of steel balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

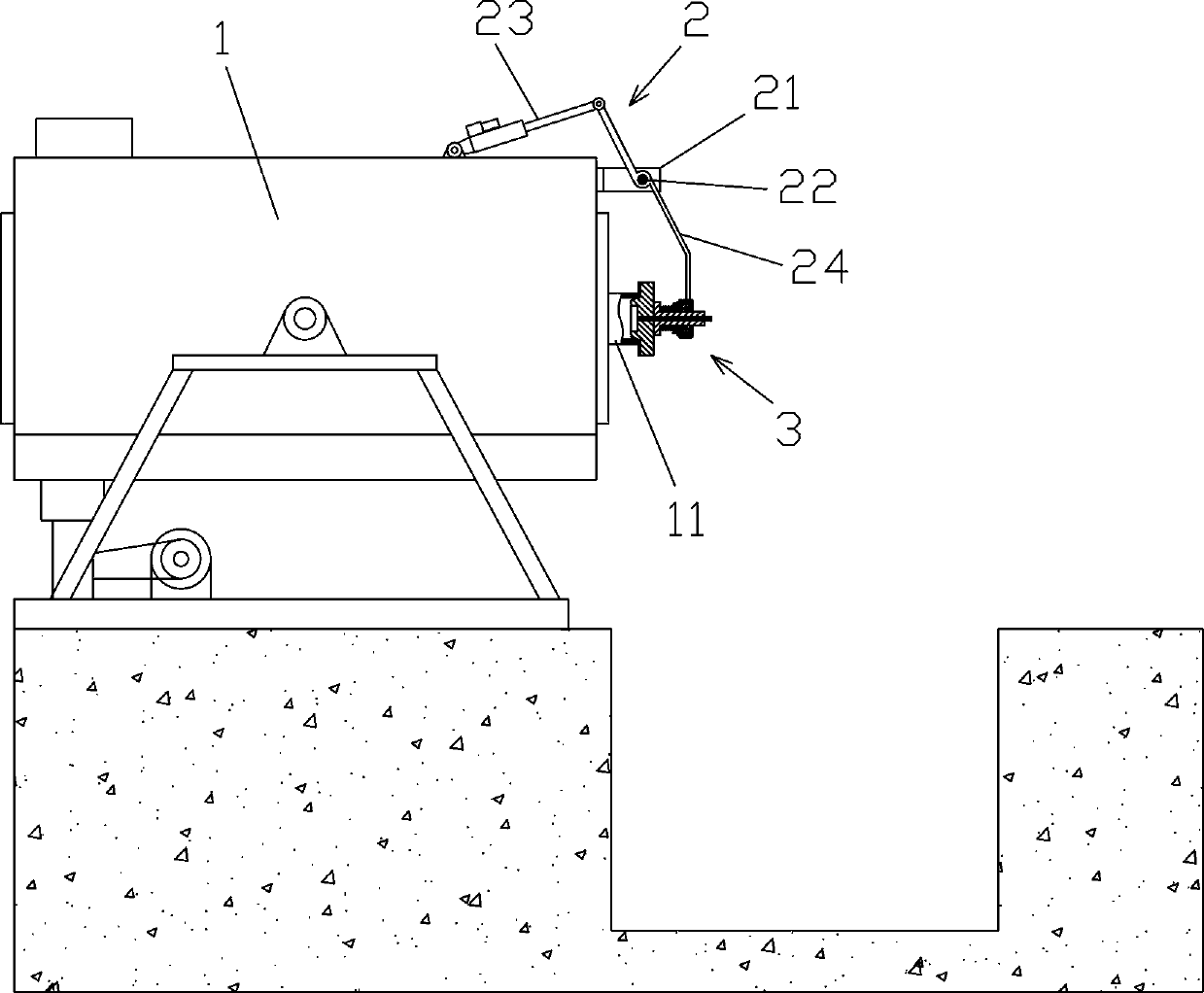

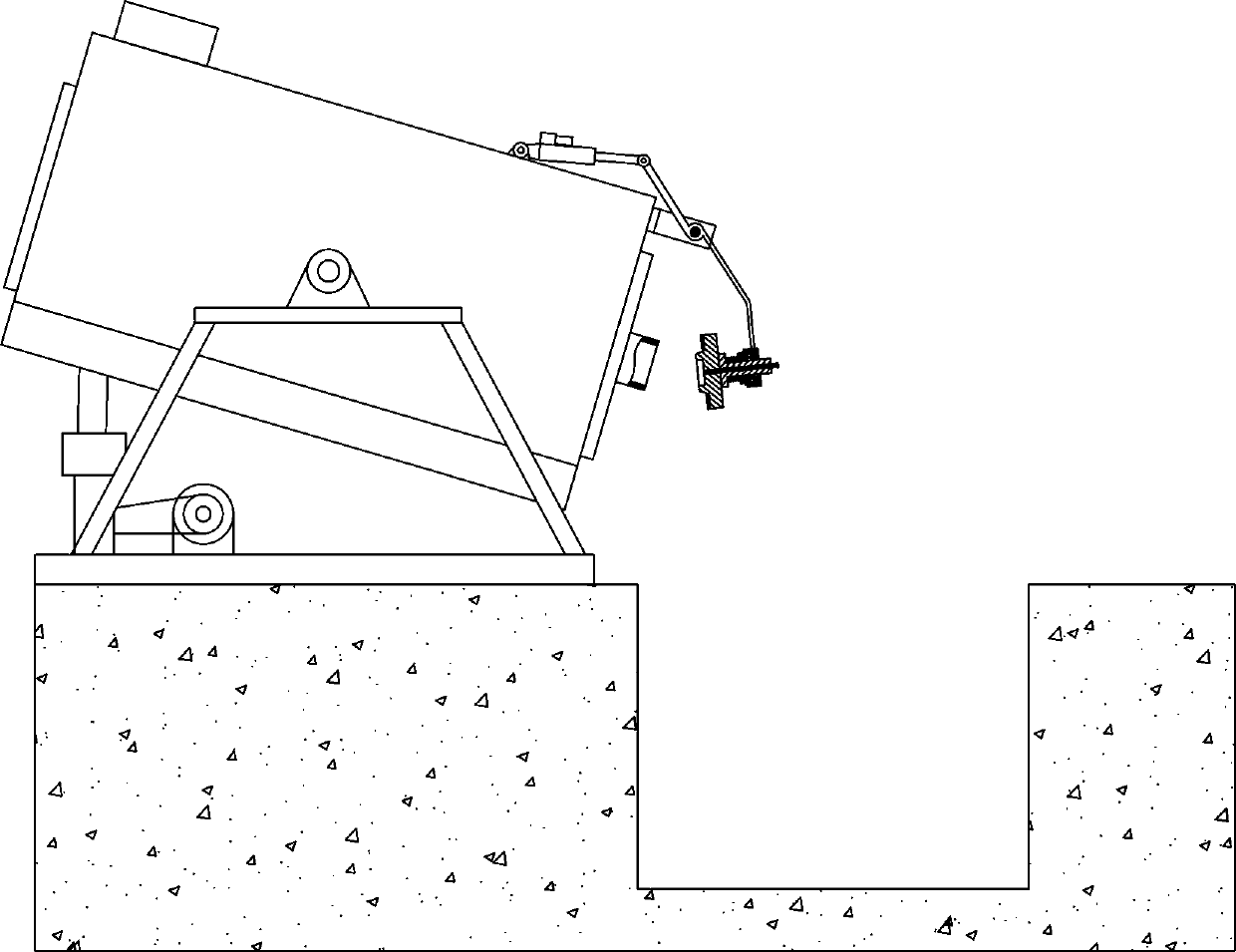

[0016] Such as Figures 1 to 3 As shown, a steel ball heat treatment furnace includes a furnace body 1, the furnace body 1 has a discharge pipe 11, an opening mechanism 2 is installed on the furnace body 1, and a closing device 3 is connected to one end of the opening mechanism 2;

[0017] The opening mechanism 2 includes an electric telescopic rod 23, a support 21 fixedly connected to the body of furnace 1, a rotating shaft 22 whose axis is connected to the support 21, and a rocker 24 whose middle shaft is connected to the rotating shaft 22, and one end of the electric telescopic rod 23 It is hinged with the furnace body 1, and the other end is hinged at the upper end of the rocker 24;

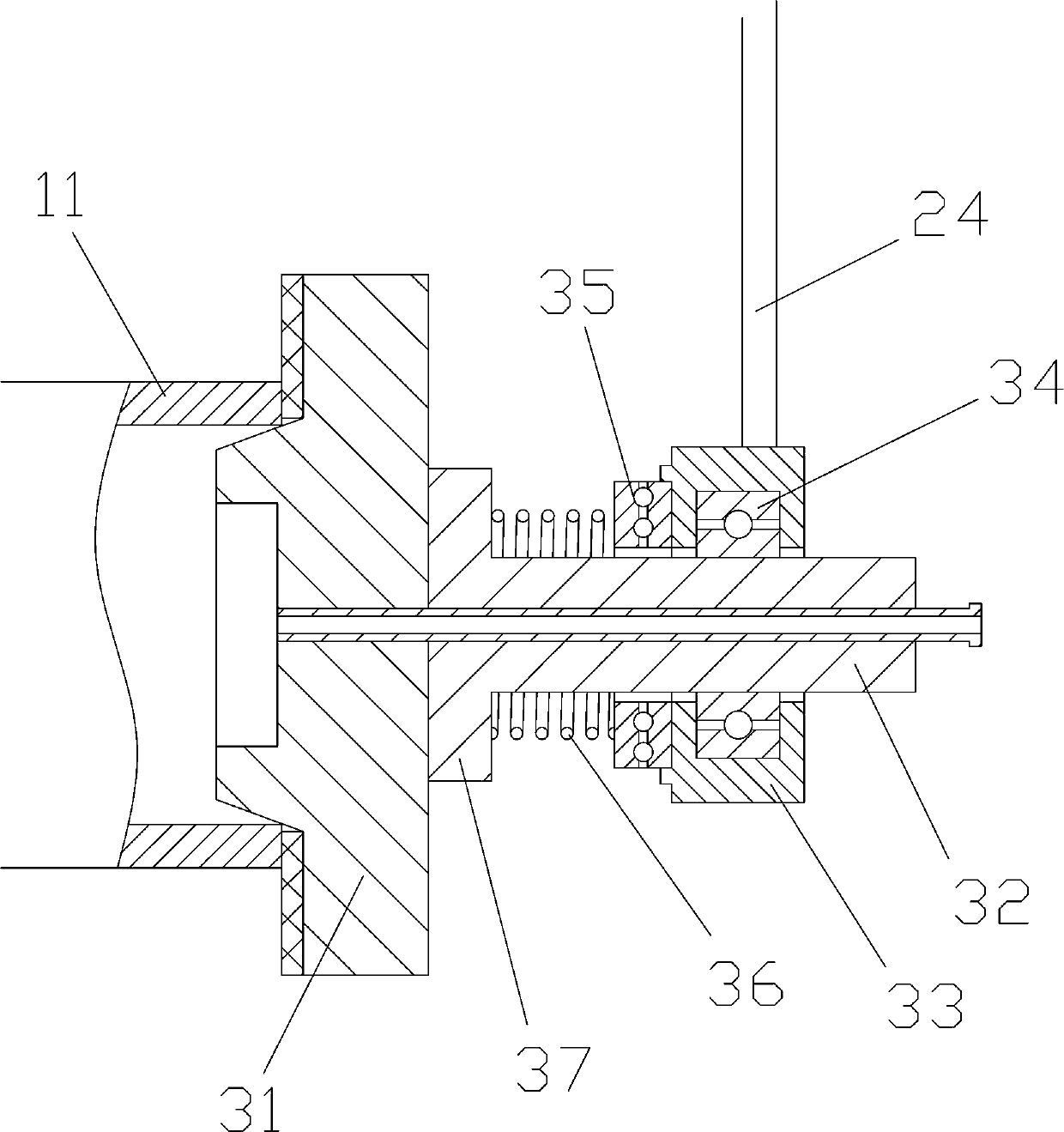

[0018] The closure device 3 includes a furnace cover 31 and a housing 33. The housing 33 is provided with a first bearing 34, and a hollow shaft 32 is installed in the first bearing 34. One end of the hollow shaft 32 is fixedly connected with the furnace cover 31. A through hole communicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com