Visible light photocatalytic functional treatment liquid for wood lacquer coating surface and preparation method thereof

A visible light and photocatalytic technology, applied in the field of coatings, can solve problems such as failure to meet environmental protection requirements, cadmium sulfide toxicity, etc., and achieve the effects of enhancing photolysis ability, improving photocatalytic effect, and improving photocatalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

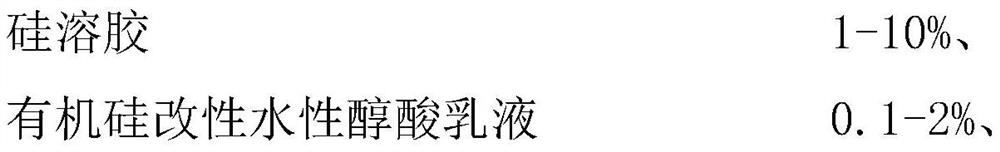

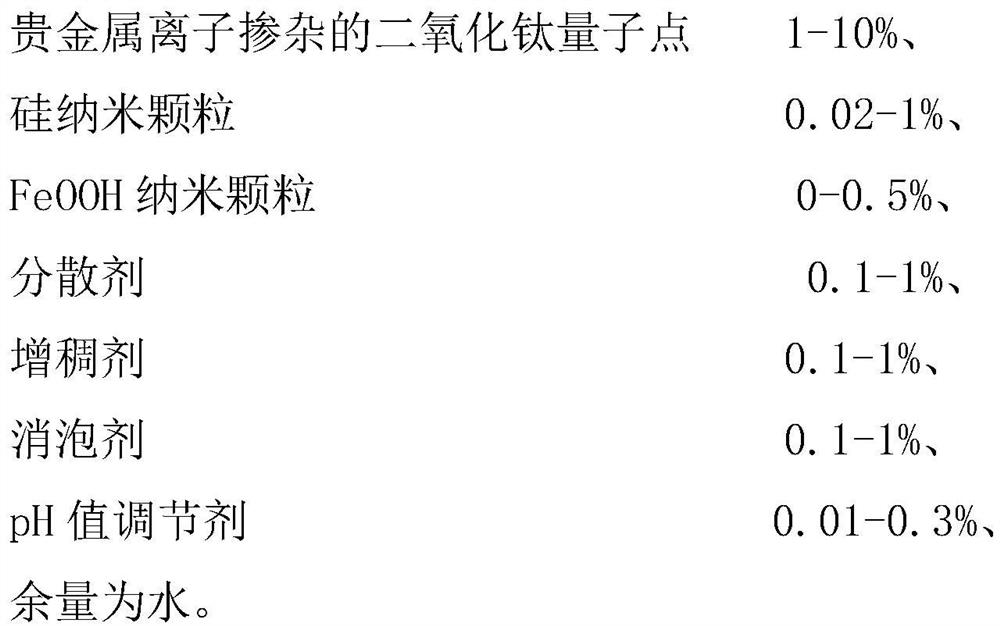

[0032] A kind of visible light photocatalytic functional treatment liquid for the surface of wood lacquer coating, comprising the following components by weight percentage:

[0033]

[0034] The preparation method is as follows:

[0035] c) Add silicon nanoparticles into water to activate and stir for later use; add titanium dioxide quantum dots doped with noble metal ions according to the ratio, and use a ball mill at a speed of 70-1500 rpm for 0.25-1 hour to form a suspension ;

[0036] d) Add silica sol to the suspension obtained in step a), and ball mill for 0.25-1 hour until uniform; then add dispersant, thickener, defoamer, pH regulator, silicone modified water-based alkyd emulsion Use a ball mill to grind for 0.5-6 hours until it is uniform, and obtain a visible light photocatalytic functional treatment liquid for the surface of the wood paint coating, put it into a packaging container, and fill it with nitrogen gas at a pressure of 0.10-0.13 MPa for packaging.

Embodiment 2

[0038] The formula and preparation method in this embodiment are similar to Example 1, the only difference is that instead of using silicon nanoparticles with a particle size less than 8nm in this embodiment, silicon nanoparticles with a particle size of 20-200nm are used, and the rest are the same as those in Example 1. 1 is the same.

Embodiment 3

[0040] A kind of visible light photocatalytic functional treatment liquid for the surface of wood lacquer coating, comprising the following components by weight percentage:

[0041]

[0042] The preparation method is as follows:

[0043] a) Add silicon nanoparticles into water to activate and stir for later use; add noble metal ion-doped titanium dioxide quantum dots and FeOOH nanoparticles according to the proportion, and use a ball mill at a speed of 70-1500 rpm for 0.25-1 hour until uniform , forming a suspension;

[0044] b) Add silica sol to the suspension obtained in step a), and ball mill for 0.25-1 hour until uniform; then add dispersant, thickener, defoamer, pH regulator, silicone modified water-based alkyd emulsion Use a ball mill to grind for 0.5-6 hours until it is uniform, and obtain a visible light photocatalytic functional treatment liquid for the surface of the wood paint coating, put it into a packaging container, and fill it with nitrogen gas at a pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com